High-precision film thickness measuring system and method

A measurement system, high-precision technology, applied in the direction of measurement devices, ion implantation plating, coating, etc., can solve problems such as poor reliability, increase in the oscillation frequency of quartz crystals, and affect the optical characteristics of products, so as to avoid power failure and reliable The effect of transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

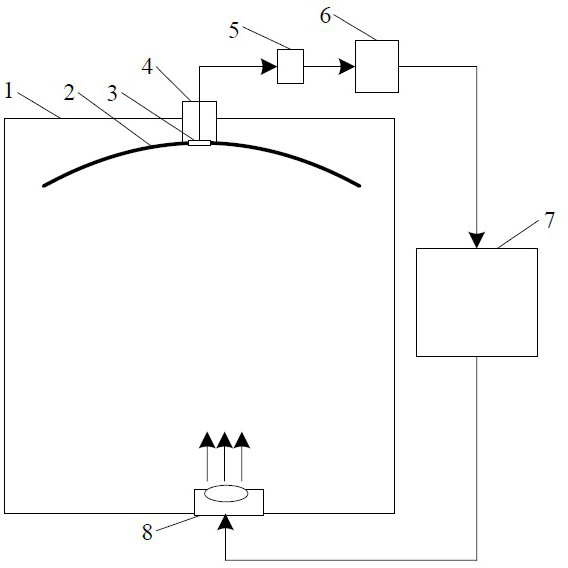

Problems solved by technology

Method used

Image

Examples

Embodiment 1

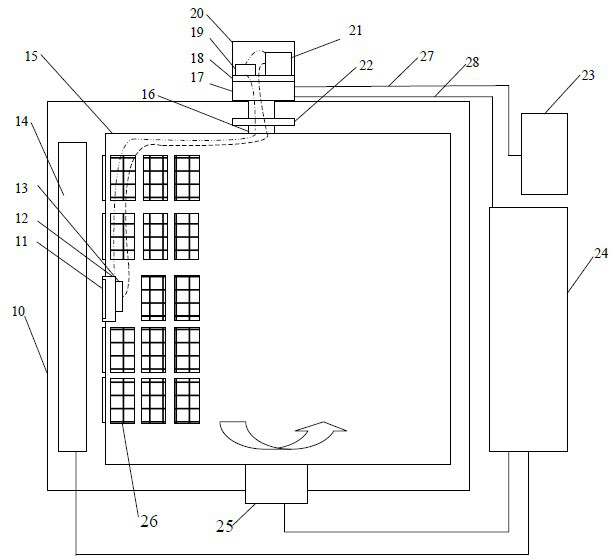

[0038] Embodiment 1 (horizontal sputtering):

[0039] Such as figure 2Shown is a vertical rotary magnetron sputtering vacuum equipment, including a vacuum chamber 10, a quartz crystal 11, a wafer probe 12, a temperature sensor 13, multiple sets of sputtering targets 14, a rotating workpiece holder 15, a rotating shaft 16, a slip ring 17, Encoder 18, oscillation package 19, film thickness gauge mounting bracket 20, film thickness gauge 21, vacuum feed flange 22, industrial computer 23, electric control cabinet 24, rotating motor 25, workpiece 26.

[0040] The film thickness measurement system includes: quartz crystal 11, wafer probe 12, oscillation package 19, film thickness gauge 21, film thickness gauge mounting bracket 20, temperature sensor 13, encoder 18, slip ring 17, supercapacitor and vacuum feed flange twenty two.

[0041] The quartz crystal 11 is installed in the wafer probe 12 , installed on the vertical surface of the workpiece holder 15 , and rotates with the wo...

Embodiment 2

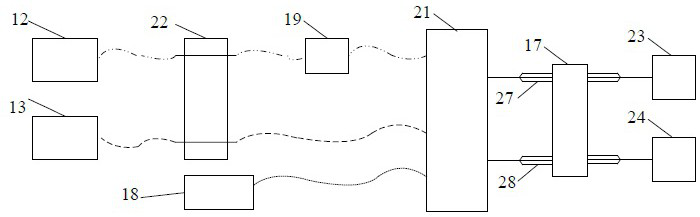

[0052] See Figure 4 , is a schematic diagram of a vertical sputtering structure according to another embodiment of the present invention. The quartz crystal 11 is installed in the wafer probe 12 , installed on the horizontal plane of the workpiece holder 15 , and rotates with the workpiece holder 15 . The coaxial cable of the wafer probe 12 is connected to the oscillating package 19 through the vacuum feeding flange 22 , and the oscillating package 19 is connected to the film thickness gauge 21 through the coaxial cable. The oscillating package 19 and the film thickness gauge 21 are installed in the film thickness gauge mounting bracket 20 outside the vacuum chamber. The film thickness gauge mounting bracket 20 is set on the upper end of the workpiece rack rotating shaft 16, rotates with the workpiece rack 15, and remains relatively stationary with the wafer probe 12 . A rotary motor 25 is installed on the top of the cavity 10 to drive the workpiece holder 15 to rotate horiz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com