Sintering machine tail high-temperature smoke synergistic trapping device and method thereof

A soot and high temperature technology is applied in the field of high-temperature soot-efficiency trapping devices at the tail of a sintering machine, which can solve the problems of strong lifting effect, large volume of high-temperature flue gas, and unreasonable structure of dust hood.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

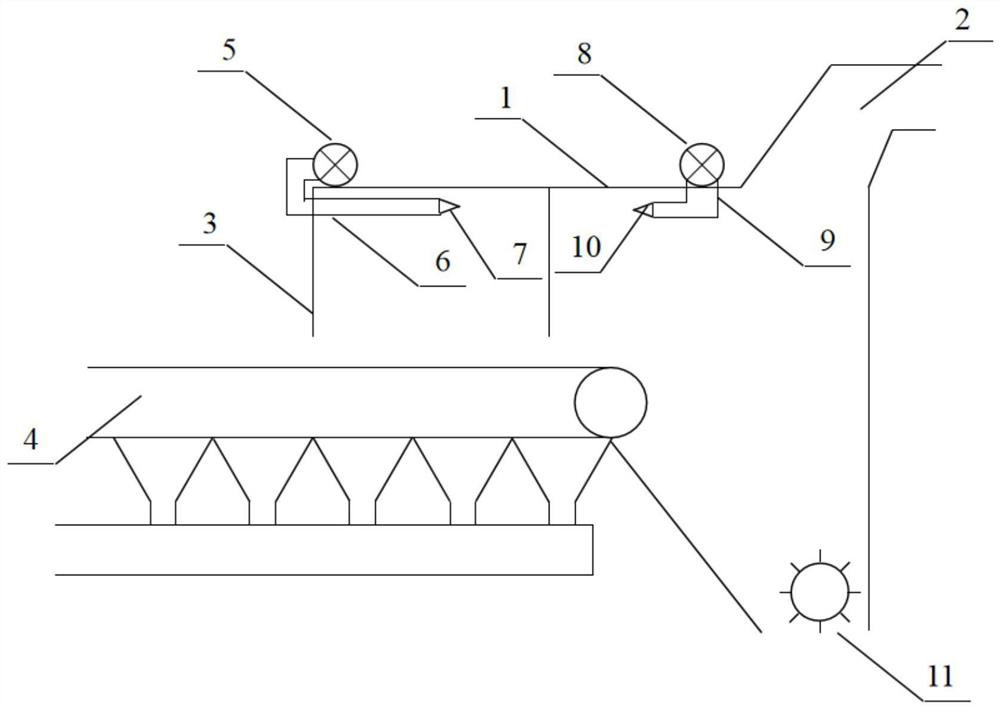

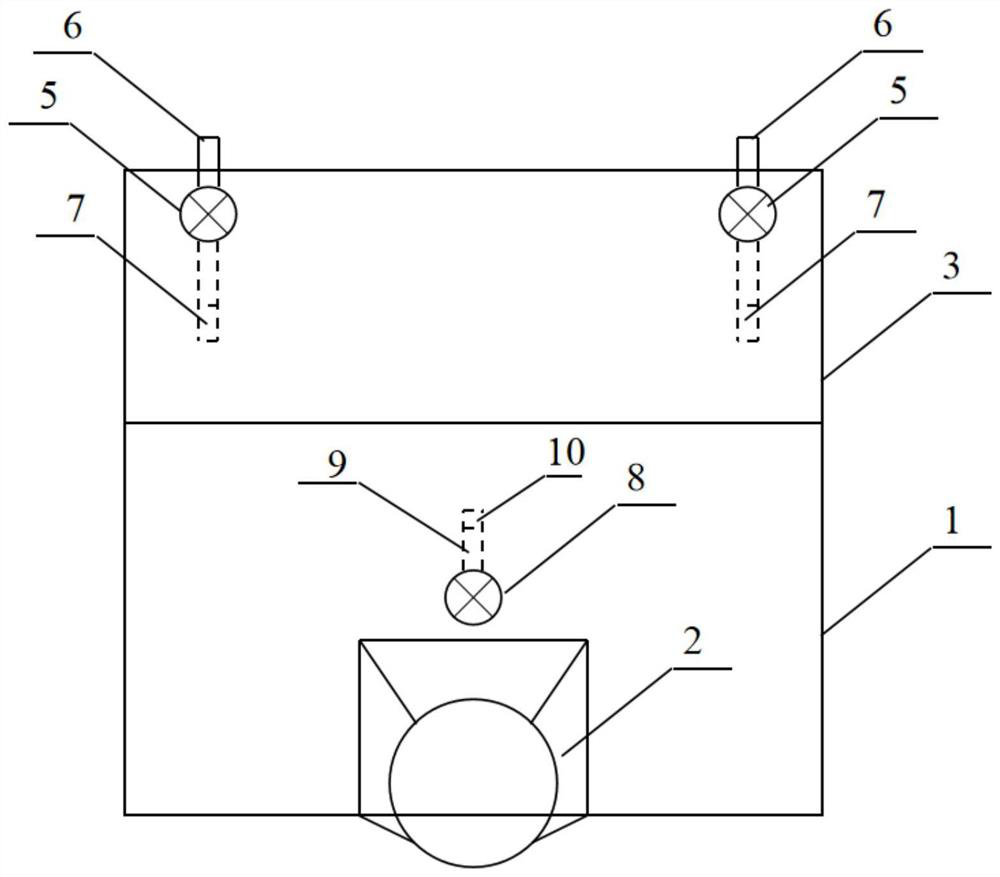

[0050] According to another specific embodiment of the present invention, another device and method for synergistically collecting high-temperature smoke and dust at the tail of a sintering machine are provided, including the following steps:

[0051] S1: Feeding, the sintered ore is transported to 2 to 3 trolleys at the tail of the sintering machine through the sintering trolley 4, and the sintering ore is covered by the expansion cover 3 and the tail cover 1;

[0052] S2: Jet flow, the air flow ejected from the forward jet flow subsystem and the reverse jet flow subsystem of the jet jet system together form an air curtain to form a directional vortex at the rear of the cover, and the air curtain covers the sintering machine within the attenuation distance end;

[0053] S3: crushing, the sintered ore falls and is crushed by the single roll crusher 11, generating high-temperature smoke and dust during crushing;

[0054] S4: Suction and dust removal, the suction hood 2 connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com