Simulation method for wet chemical etching process of flexible PCB

A PCB board and wet chemical technology, which is applied in the field of flexible PCB board preparation and flexible PCB board wet chemical etching process simulation, can solve the problems of relying on manual experiments, high cost, and long time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

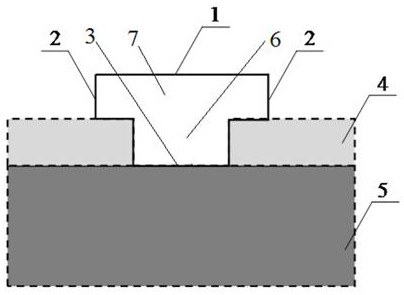

[0036] In order to facilitate the understanding of the embodiments of the present invention, specific embodiments will be taken as examples for further explanation below in conjunction with the accompanying drawings, and each embodiment does not constitute a limitation to the embodiments of the present invention.

[0037] The copper film is used as the etching substrate below, and the CuCl 2 The solution will be described as an etching solution as an example.

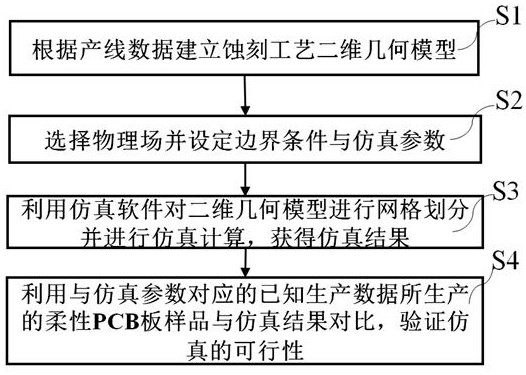

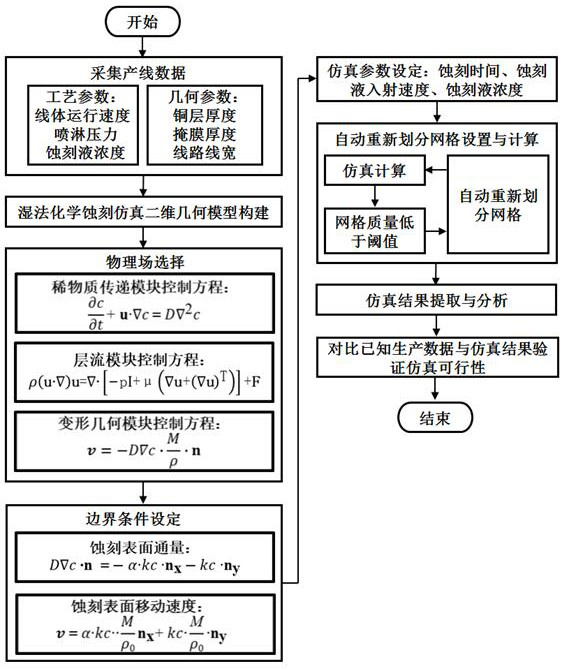

[0038] Such as figure 1 As shown, a method for simulating a flexible PCB wet chemical etching process provided in this embodiment includes the following steps:

[0039] S1, establish a two-dimensional geometric model of the etching process according to the production line data;

[0040] S2, select the physical field module and set boundary conditions and simulation parameters;

[0041] S3, using simulation software to mesh the two-dimensional geometric model and perform simulation calculations to obtain simulation r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com