Preparation method of single crystal NCM ternary positive electrode material precursor

A technology of cathode materials and precursors, which is applied in the field of preparation of single crystal NCM ternary cathode material precursors, can solve the problems of the influence of cathode material performance, poor particle uniformity, and difficulty in sintering subsequent cathode materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

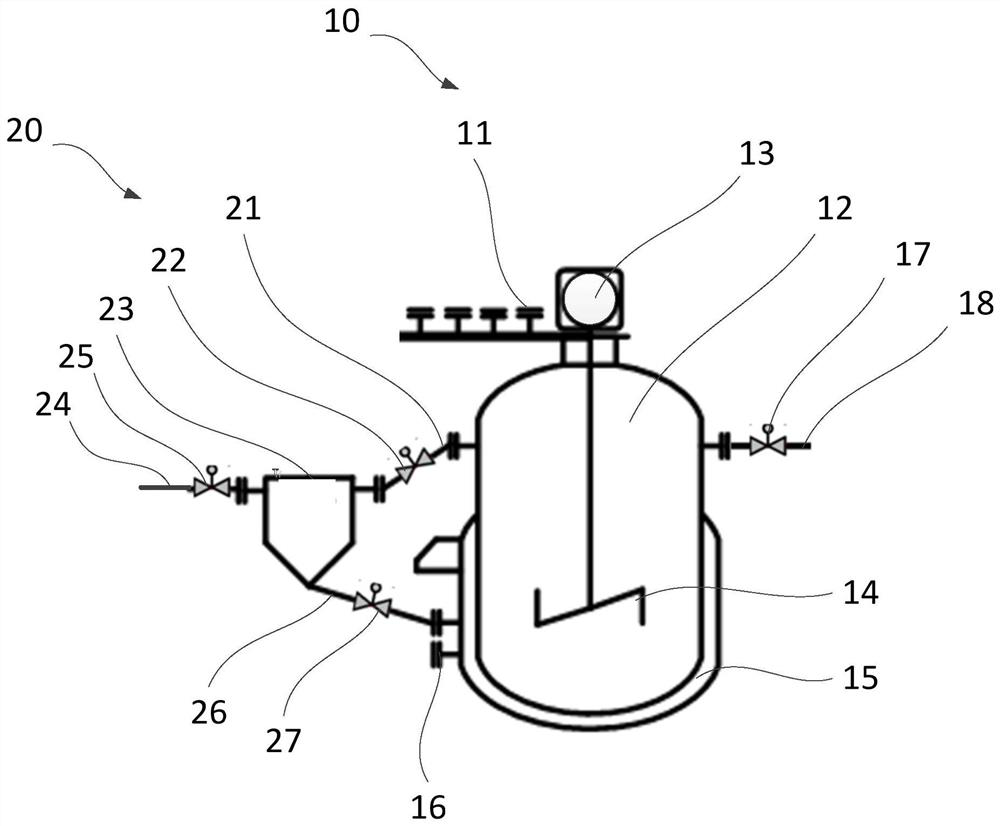

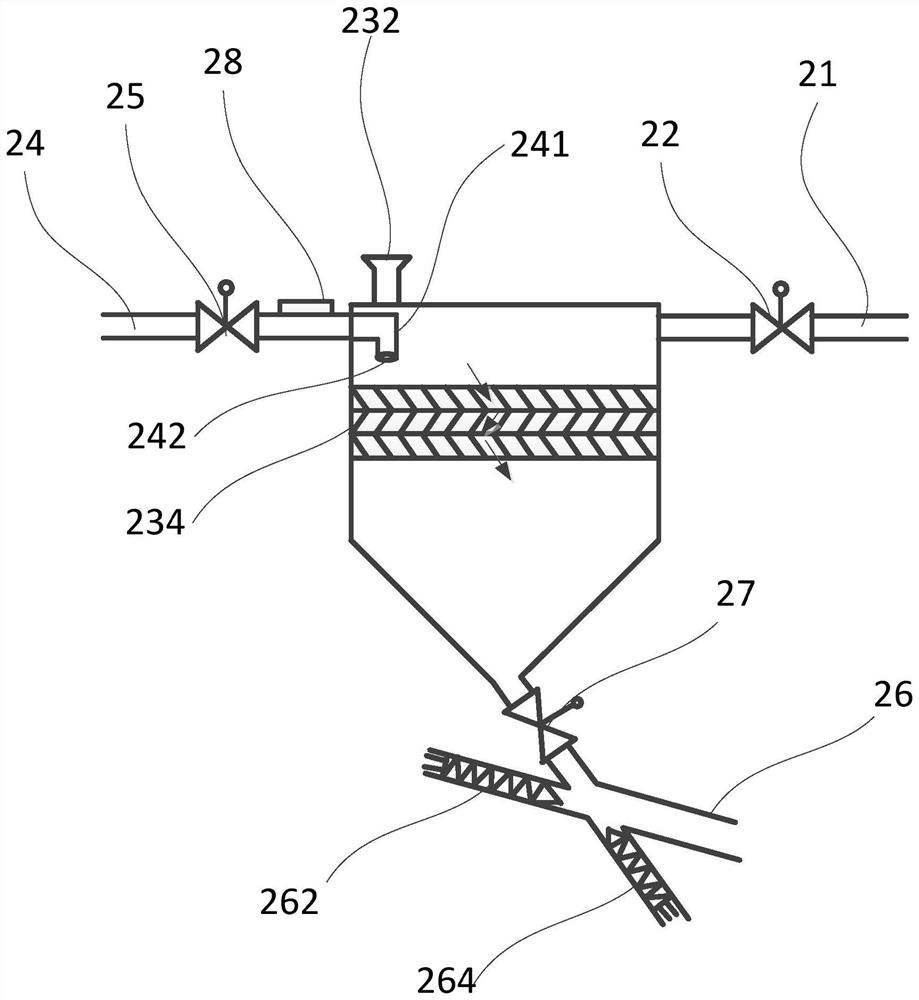

[0030] Please refer to Figure 4 , a method for preparing a single crystal NCM ternary positive electrode material precursor based on a particle size controllable reactor, the particle size controllable reactor comprising: a reaction unit (10) and a solid extraction unit (20); the preparation Methods include:

[0031] S1, Ni with a total concentration of 1.0-2.2mo1 / L according to the proportion x :Co y :Mn z Sulphate solution, 4-10mol / L caustic soda solution and 20% ammonia water are added into the reaction unit (10) and an inert gas is fed into the first-stage reaction at the same time, wherein the reaction conditions are: the stirring speed is 800-1100r / min , the pH is 11.50~13.00, the temperature is 40~60℃, and the inert gas flow rate is 0.1~2m 3 / h, and x+y+z=1, 1.0>x≥0.5;

[0032] S2, after measuring particle D50 = 1.5-1.8 μm, increase the ammonia value in the reactor to carry out the second-stage reaction, wherein the reaction conditions are: keep the stirring speed...

Embodiment 1

[0038] According to the molar ratio of nickel, cobalt and manganese ions as 60:20:20, prepare NiSO with a concentration of 1.6mol / L 4 、CoSO 4 , MnSO 4 For the mixed solution, use a precision metering pump to add the mixed solution, 8mol / L caustic soda solution, and 20% industrial ammonia water filtered by a 200-mesh filter cloth into the reaction vessel 12 to carry out the first-stage reaction, and the stirring speed of the reactor is 1050r / min, the pH is 12.30, the temperature is 55°C, and nitrogen is maintained at 0.2m 3 / h long pass, reaction 1.5h; In the second stage, after using the Dandong Baite 2600 model particle size analyzer to measure the particle D50=1.5 μm, control the ammonia value in the reaction vessel 12 at 3-4g / L, and control the pH to 10.60. Open the overflow valve 17, the solid lifting valve 22 and the backflow valve 27, and open the drain valve 24 by 15%, filter the mother liquor with a solid lifting device to concentrate to improve the solid content an...

Embodiment 2

[0040] According to the molar ratio of nickel, cobalt and manganese ions as 65:15:20, prepare NiSO with a concentration of 1.6mol / L 4 、CoSO 4 , MnSO 4 For the mixed solution, use a precision metering pump to add the mixed solution, 8mol / L caustic soda solution, and 20% industrial ammonia water filtered by a 200-mesh filter cloth into the reaction vessel 12 to carry out the first-stage reaction, and the stirring speed of the reactor is 1030r / min, pH is 12.22, temperature is 55°C, nitrogen gas is kept at 0.3m 3 / h long pass, reaction 1.5h; In the second stage, after using the Dandong Baite 2600 model particle size analyzer to measure the particle D50=1.5 μm, control the ammonia value in the reaction vessel 12 at 3-4g / L, and control the pH to 10.50. Open the overflow valve 17, the solid lifting valve 22 and the backflow valve 27, and open the drain valve 24 by 15%, filter the mother liquor with a solid lifting device to concentrate to improve the solid content and adjust the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com