High weather resistance polyester for solar backplane multilayer film bonding and its synthesis method

A technology for solar back sheets and multi-layer films, applied in the direction of adhesives, etc., can solve the problems of increasing total reaction time, increasing energy consumption and production cost, and achieving the effects of low cost, improved weather resistance, and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

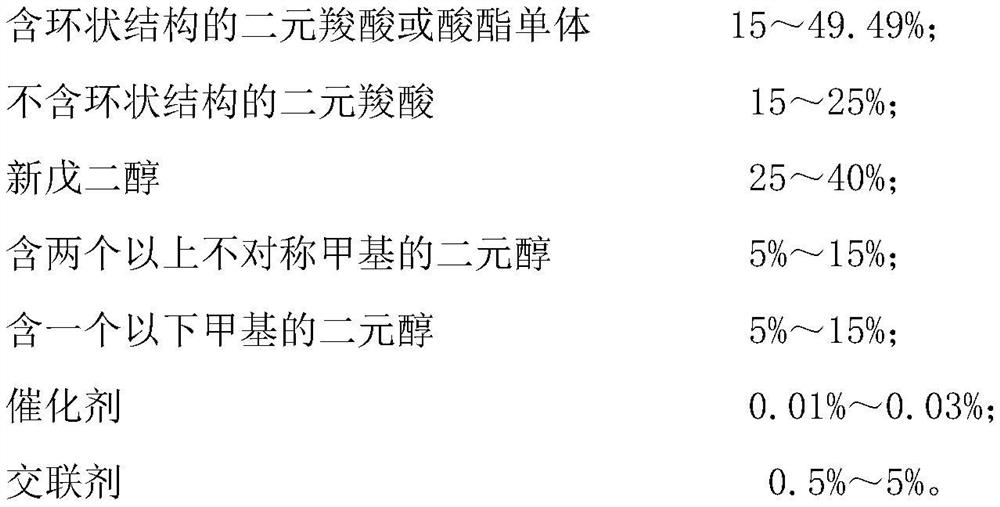

Method used

Image

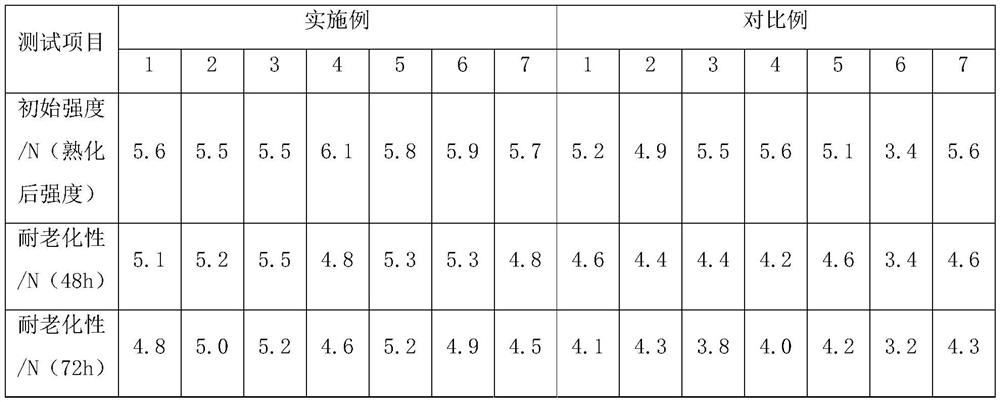

Examples

Embodiment 1

[0031] This embodiment provides a kind of highly weather-resistant polyester used for solar backboard multilayer film bonding, and its preparation method comprises the following steps:

[0032] (1) Put 20kg of terephthalic acid, 40kg of isophthalic acid, 36kg of sebacic acid, 60kg of neopentyl glycol, 15kg of 2-methyl-2,4-pentanediol, and 14kg of 1,5-pentanediol into the reaction Stir and heat in the kettle at a temperature of 120°C to 140°C. After the material is melted, add 36g (the unit is g) of dihydroxybutyl tin chloride, and gradually raise the temperature to 220°C to 240°C for reaction. When it is measured that the lactonization rate in the kettle is more than 94%, start vacuuming, and gradually increase the vacuum until the hydroxyl value of the material in the kettle is 56±4mgKOH / g.

[0033] (2) Reduce the temperature in the kettle to below 160°C, put in 3kg of trimethylolpropane, gradually raise the temperature to 240°C, keep it warm for 2 hours, start vacuuming, an...

Embodiment 2

[0036] This embodiment provides a kind of highly weather-resistant polyester used for solar backboard multilayer film bonding, and its preparation method comprises the following steps:

[0037] (1) 17kg phthalic anhydride, 44kg isophthalic acid, 36kg sebacic acid, 58kg neopentyl glycol, 15kg 2,2,4-trimethyl-1,3-pentanediol, 12kg 1, Put 5-pentanediol into the reaction kettle and stir and heat at a temperature of 120°C to 140°C. After the material is melted, add 36g (the unit is g) of dihydroxybutyl tin chloride, and gradually raise the temperature to 220°C to 240°C for reaction. When it is measured that the lactonization rate in the kettle is more than 94%, start vacuuming, and gradually increase the vacuum until the hydroxyl value of the material in the kettle is 56±4mgKOH / g.

[0038] (2) Reduce the temperature in the kettle to below 160°C, put 5.1kg of pentaerythritol into it, gradually raise the temperature to 240°C and keep it warm for 2 hours, start vacuuming, and gradual...

Embodiment 3-7

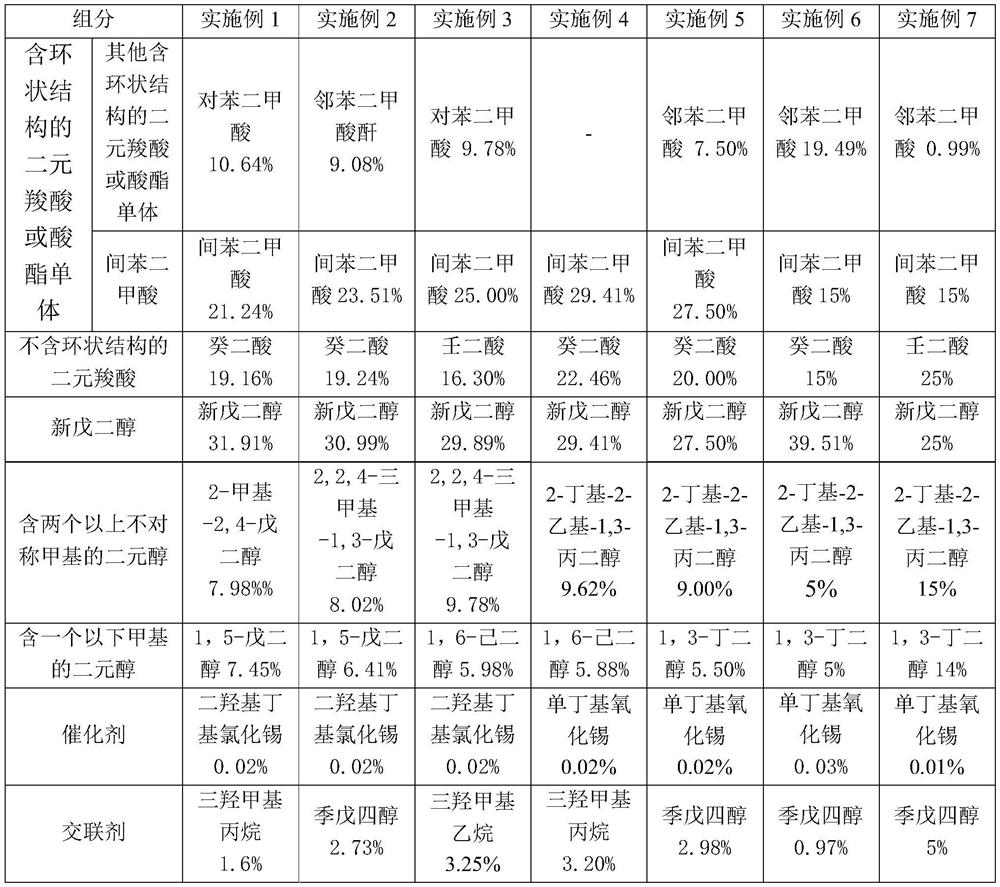

[0041] Examples 3-7 respectively provide a kind of high weather resistance polyester used for solar backplane multilayer film bonding, and the specific components and contents are shown in Table 1; the preparation method is the same as that of Example 1.

[0042] Table 1

[0043]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com