Preparation method and application of film material with spectrally selective reflection colorful coating

A technology of reflective coatings and thin-film materials, applied in coatings, polyester coatings, film/sheet release coatings, etc., can solve the market application prospect and can only be positioned in high-end products, complex production processes, high equipment and raw material costs and other problems, to achieve good thermomechanical stability, simple manufacturing process and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

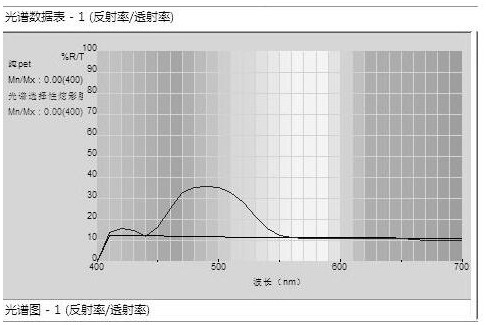

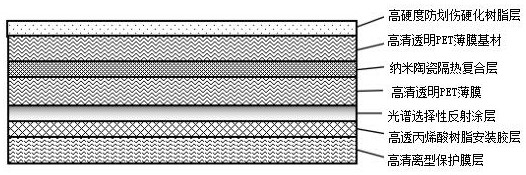

[0022] A preparation method of a spectrally selective reflective colorful coating film material is: on the corona surface of the high-transmittance optical-grade transparent PET film, the thickness of the high-transmittance optical-grade transparent PET film is selected as 20 μm, and the spectrum is selected by MG coating. Sexy colorful reflective coating, coating thickness 0.5μm, the coating surface passes through the conveying device and passes through the oven to evaporate excess solvent, and the oven temperature is 100°C; the baking time is 50S, and the coated surface passes through the conveying device and passes through the UV light curing machine to fix the pitch gradient , where the radiation intensity of the UV light curing machine is 300mj / cm², the colorful coating film material with spectral selective reflection can be obtained.

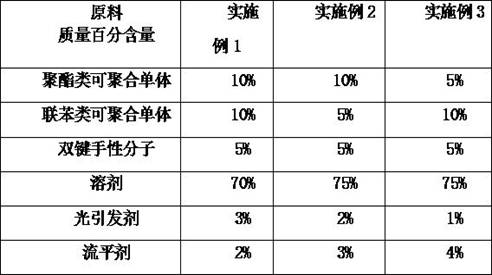

[0023] Wherein the ratio of raw materials of the spectrally selective colorful reflective coating of embodiment 1-3 is shown in Table 1: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com