Buck circuit silicon carbide power module

A technology of power modules and silicon carbide, which is applied in the direction of circuits, electrical components, and electric solid-state devices, and can solve problems such as high parasitic inductance, uneven current of switching tubes, and low power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

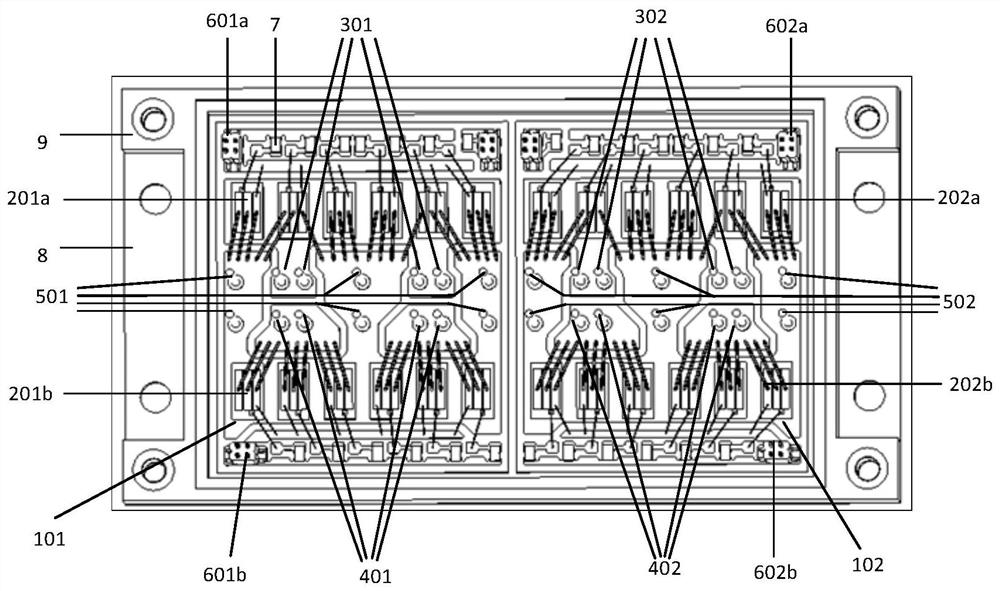

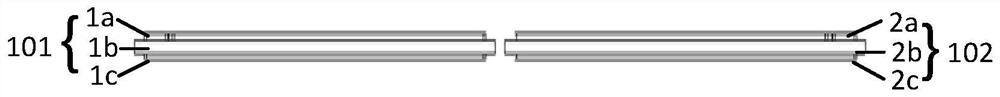

[0024] figure 1 A schematic diagram of the structure of the buck circuit silicon carbide power module provided in this example is shown, the module includes DBC substrates 101 and 102, silicon carbide power chip 201a, silicon carbide power chip 201b, silicon carbide power chip 202a, silicon carbide power chip 202b , positive power terminals 301 and 302, negative power terminals 401 and 402, output power terminals 501 and 502, drive terminal 601a, drive terminal 601b, drive terminal 602a, drive terminal 602b, drive resistor 7, base plate 8 and packaging shell 9. Among them, the silicon carbide power chip 201a and the silicon carbide power chip 201b constitute the first buck half-bridge circuit, which is welded on the DBC substrate 101, and the silicon carbide power chip 202a and the silicon carbide power chip 202b constitute the second buck half-bridge circuit, which is welded on the DBC substrate 102 on.

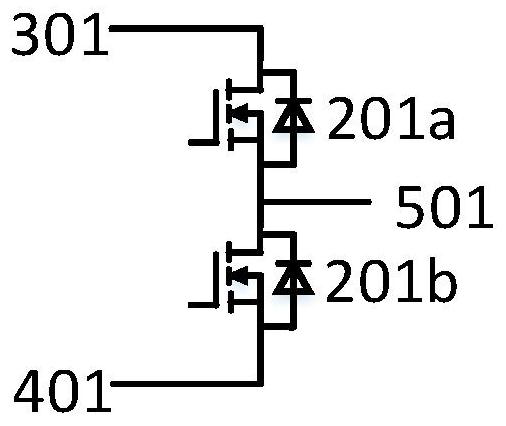

[0025] figure 2 A schematic circuit structure diagram of the first b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com