Dustproof ionic polymer, preparation method thereof and dustproof shed film

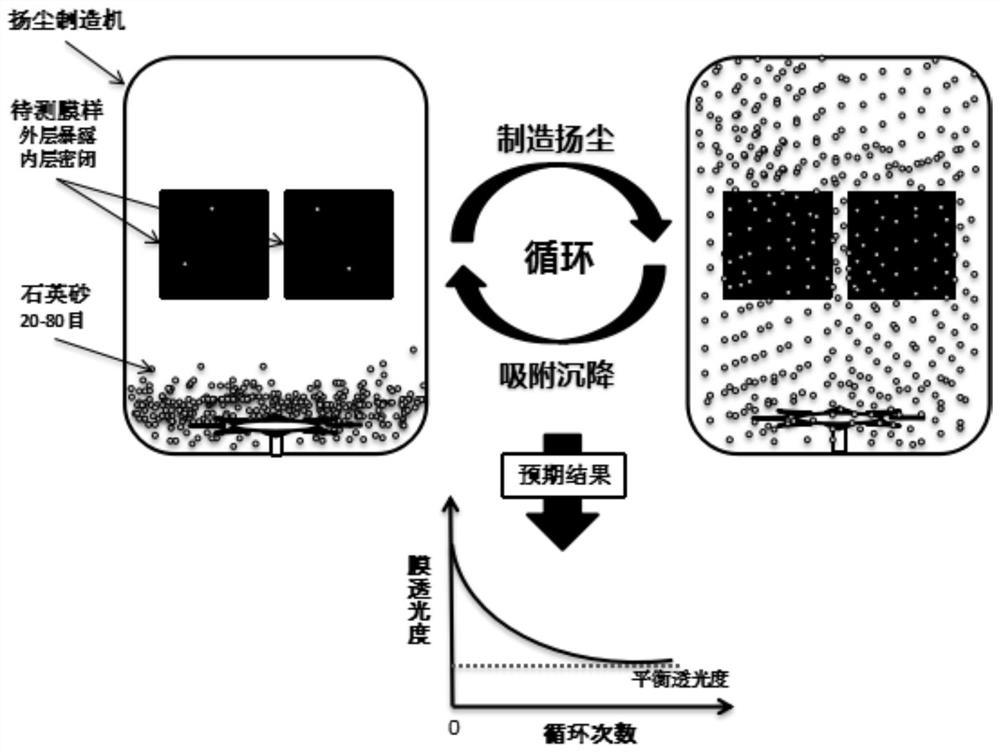

An ionic polymer, dust-proof technology, applied in the directions of botanical equipment and methods, chemical instruments and methods, synthetic resin layered products, etc., can solve the problems affecting the dust-proof effect of shed film, etc. The effect of low haze and high light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] The molecules with dustproof effect used in the present invention are all self-made. The schematic diagram of the chemical structure is shown in formula (V). In the formula (V), n represents the number of repeating units of oxyethylene, and the allyl polyoxyethylene ether (selected from McLean's reagent ), using it as a raw material to prepare the corresponding dust-proof monomer.

[0077] Wherein the preparation method is as follows:

[0078] Allyl polyoxyethylene ether, acetic acid and chloroplatinic acid were mixed in a mass ratio of 70:20:10 and prepared into a 20 wt% isopropanol solution. Add the reaction kettle, then raise the temperature to 70°C and stir for 1 hour. Raise the temperature to 85°C, add heptamethyltrisiloxane dropwise, the molar ratio of methylsiloxane to allyl polyoxyethylene ether is 3:2, control the dropping rate at 40g / min, and control the temperature of the reaction solution at Below 100°C, the dropwise addition is completed in about 3 hours...

Embodiment 2

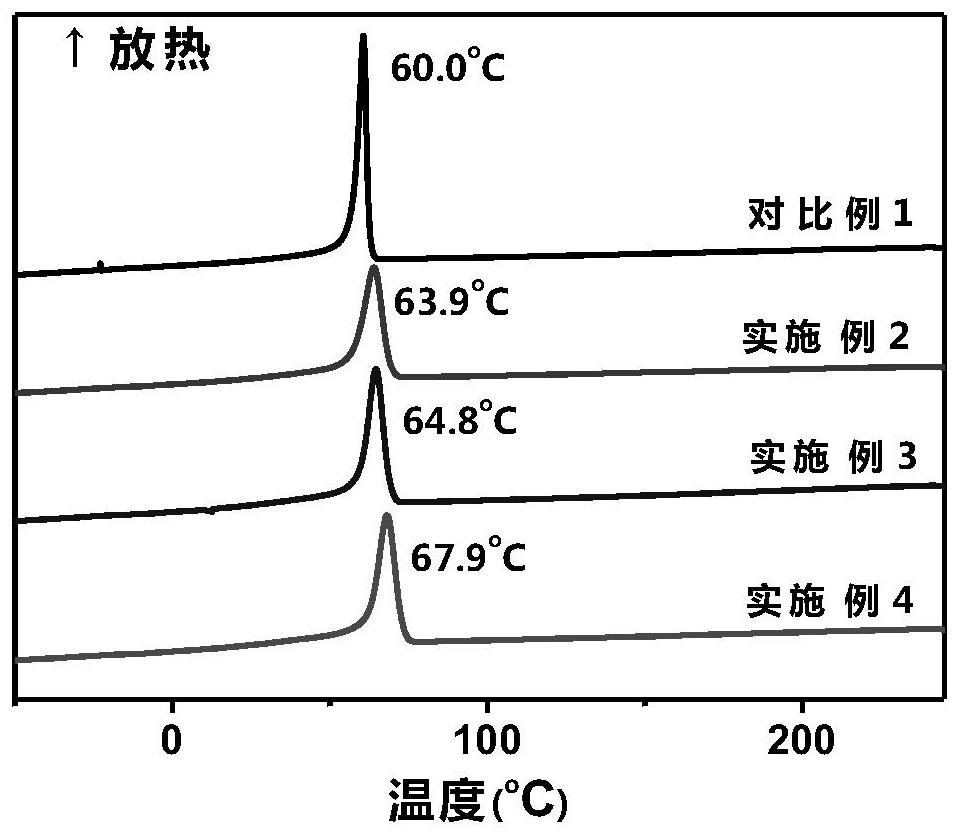

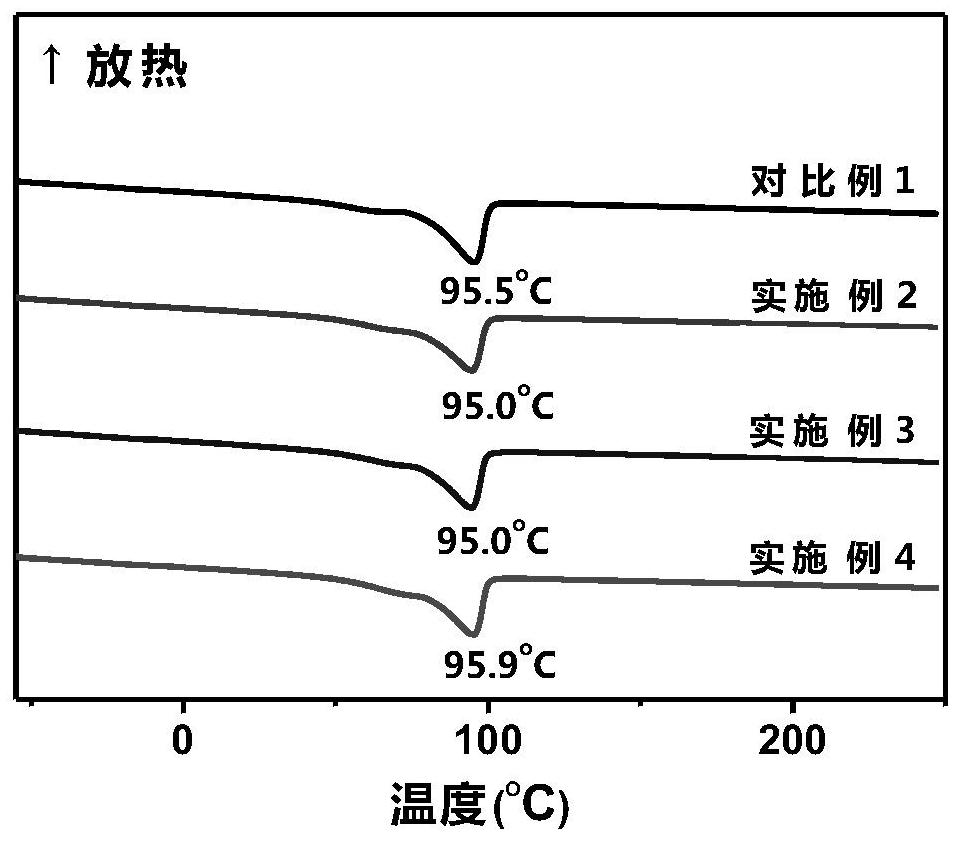

[0082] The ionic polymer used in the present invention is produced by DuPont Company, and the trade mark is Surlyn 1601-2. The initiator used in the present invention is 2,5-dimethyl-2,5-di-tert-butylperoxyhexane (double 25), which is an analytically pure product of Bailingwei Technology Co., Ltd.

[0083] Disperse the initiator in the n=0 molecules with anti-dust effect synthesized by this patent shown in formula (V), and prepare a mixed solution in which the initiator accounts for 5% of the mass fraction of the anti-dust molecules. A co-rotating twin-screw extruder (screw diameter 20mm, aspect ratio 40) from Sweden LabTech Company was selected. The mixed polyolefin particles (Surlyn 1601-2), and the mixture of molecules with dustproof effect and initiator are mixed, plasticized, reacted, and extruded. The feeding speed of polyolefin particles (Surlyn 1601-2) is 10kg / h, and the feeding rate of the mixed solution of molecules with dustproof effect and initiator is 500g / hr to ...

Embodiment 3

[0086] The ionic polymer described in Example 2 and bis-2-5 are dispersed in the molecules with dust-proof effect of n=1 synthesized by this patent shown in formula 1, and the initiator accounts for the dust-proof molecular mass fraction of 5% mixture. A co-rotating twin-screw extruder (screw diameter 20mm, aspect ratio 40) from Sweden LabTech Company was selected. The mixed polyolefin particles (Surlyn 1601-2), the mixture of molecules with dustproof effect and initiator are mixed, plasticized, reacted, extruded, and the feeding speed of polyolefin particles (Surlyn 1601-2) 6-10kg / h, the feeding speed of the mixture of molecules with dustproof effect and initiator is 500g / hr, and the dustproof modified ion polymer material is made.

[0087] The extruder has 11 sections from the feed port to the die, numbered 1-11, and the first section only plays the role of feeding and cannot be heated. The temperatures of sections 2-11 of the extruder are respectively: 150°C, 160°C, 170°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com