Mixed olefin grafted microsphere reinforced flame-retardant nylon 6 composition and preparation method thereof

A technology of flame retardant nylon and composition, applied in the field of nylon, can solve the problems of flame retardant, poor dispersion of glass fiber, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] 1. Preparation of mixed olefin grafted microspheres:

[0052] Mixed olefin grafted microspheres A

[0053] It is a copolymer microsphere of maleic anhydride, n-butene and isobutene, prepared by copolymerization of maleic anhydride, n-butene and isobutene in the presence of nitrogen, azobisisobutyronitrile (AIBN) initiator and organic solvent Mixed olefin graft copolymer microspheres A; the ratio of n-butene and isobutene is 1:1.

[0054] The weight ratio of mixed carbon four and maleic anhydride is 3:1.

[0055] The concentration of maleic anhydride in the organic solvent isoamyl acetate is 20wt%;

[0056] Initiator consumption is 1% of maleic anhydride weight;

[0057] The copolymerization reaction temperature is 80° C.; the copolymerization reaction pressure is 1 MPa; the copolymerization reaction time is 6 hours.

[0058] The particle size range of the microspheres is 5-8 microns.

[0059] Mixed olefin grafted microspheres B

[0060] It is a copolymer microsphe...

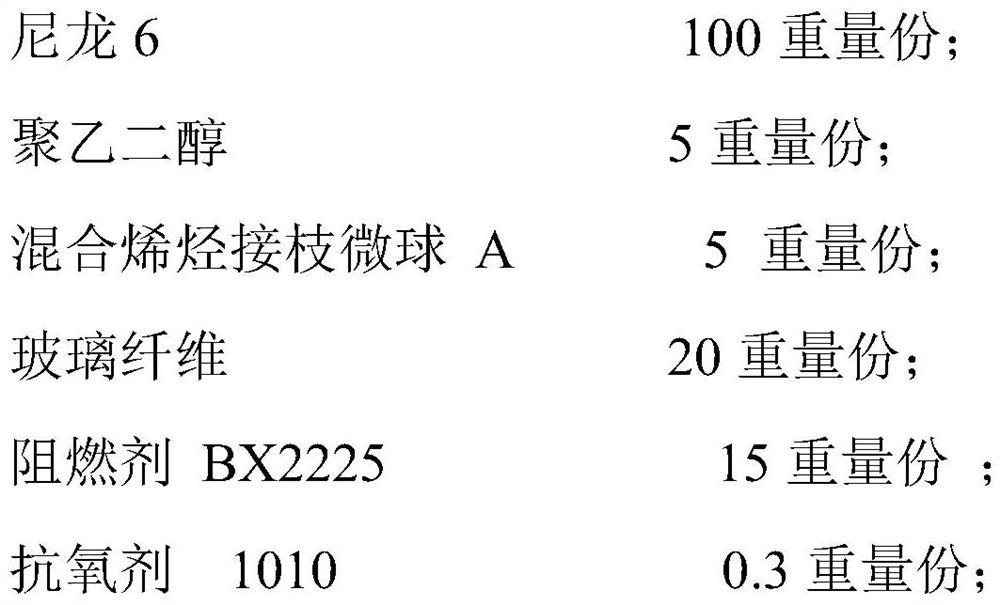

Embodiment 1

[0073]

[0074] The nylon 6 composition is prepared by melt-blending the components in the stated amounts.

[0075] The melting temperature is 230°C.

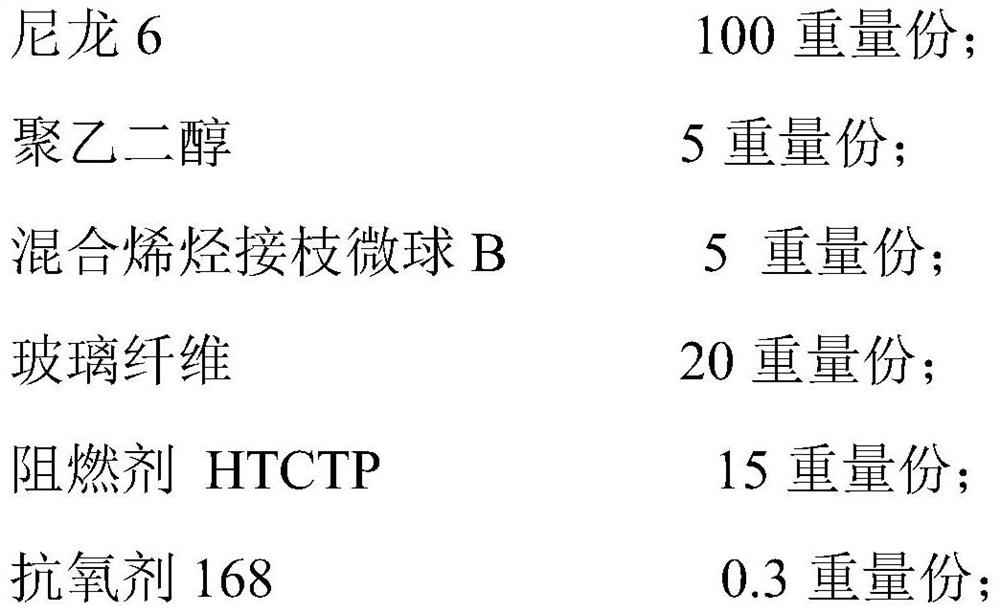

Embodiment 2

[0077]

[0078] The nylon 6 composition is prepared by melt-blending the components in the stated amounts.

[0079] The melting temperature is 235°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Melting temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com