Reverse optimization method for porous structure material design

A porous structure and reverse optimization technology, applied in the field of medical devices, can solve problems such as uneven stress distribution of workpieces, workpiece failure, and difficult workpiece structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031]In order to make the objectives, technical solutions and advantages of the present invention, the present invention will be described in further detail below with reference to the accompanying drawings and examples. It should be understood that the specific embodiments described herein are merely intended to illustrate the invention and are not intended to limit the invention.

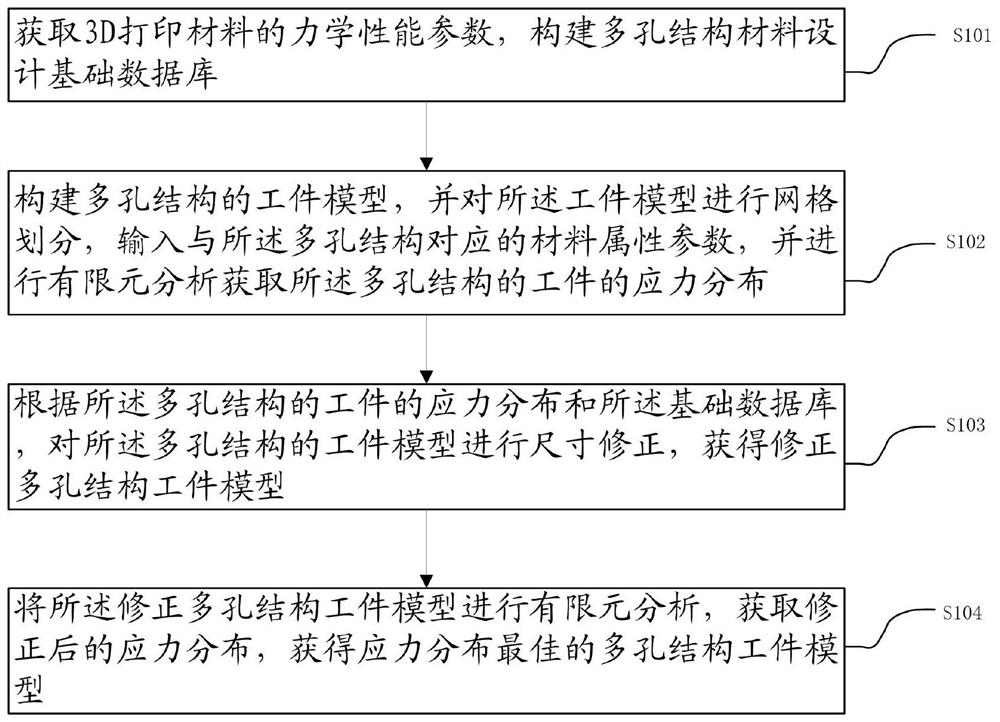

[0032]Such asfigure 1 As shown in one embodiment, a reverse optimization method for porous structural design is provided, and specifically includes the following steps:

[0033]Step 101, obtain the mechanical performance parameters of the 3D print material, and construct a multi-well structural material design underlying database.

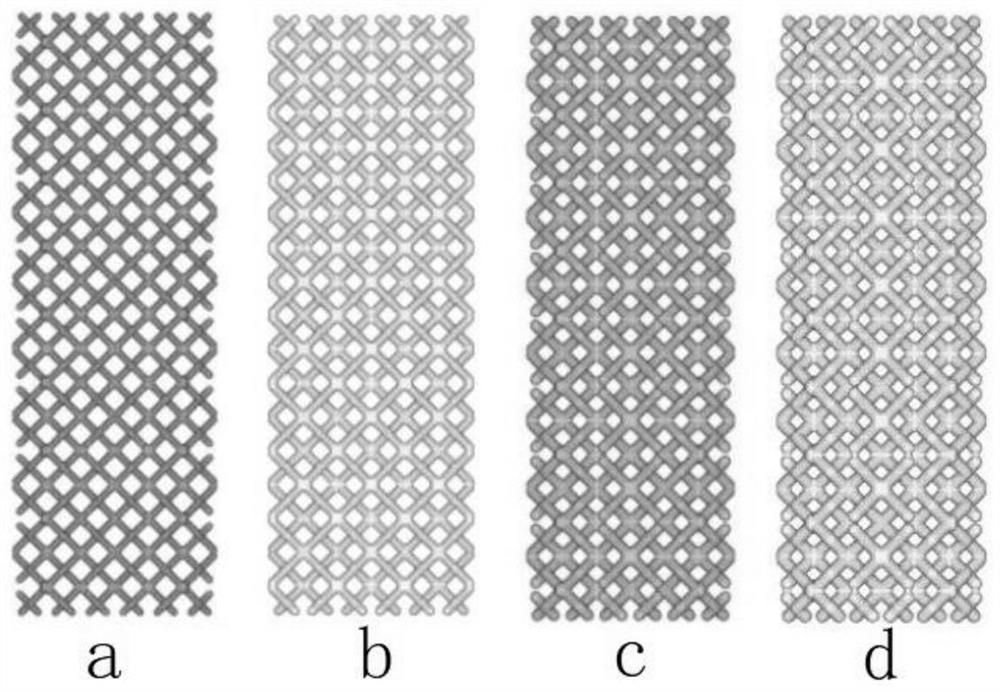

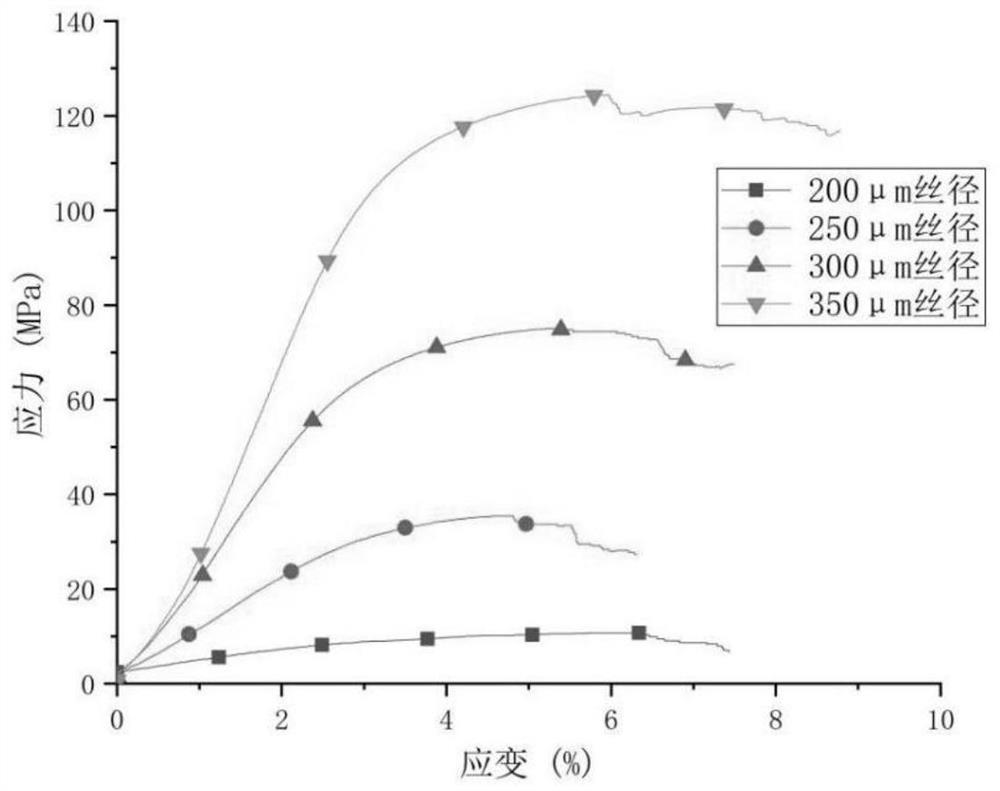

[0034]In an embodiment of the present invention, the 3D printing material used, such as stainless steel, titanium alloy, cobalt-molybdenum alloy, tantalum metal, polyether ether ketone, etc., by material, by the condition of the same structural unit size Next, the porous structural ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com