Olefin hydration reaction process and system

A technology of olefin hydration and hydration reaction, applied in hydroxyl addition preparation, organic chemistry, etc., can solve the problems of difficult catalyst loading, large catalyst particles, low reaction efficiency, etc., to prolong the shutdown period, easy liquid-solid separation, and reaction high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Examples illustrate the effect of the olefin hydration reaction method provided by the present invention.

[0044] The reaction raw material is a mixed carbon four component containing isobutene, which is taken from a catalytic cracking unit of a Sinopec refinery, and its composition is shown in Table 1. The solid acidic catalyst is D005-II resin produced by Dandong Mingzhu Special Resin Co., Ltd., with a particle size of 0.315-1.25mm and a wet true density of 1.18-1.28g / mL.

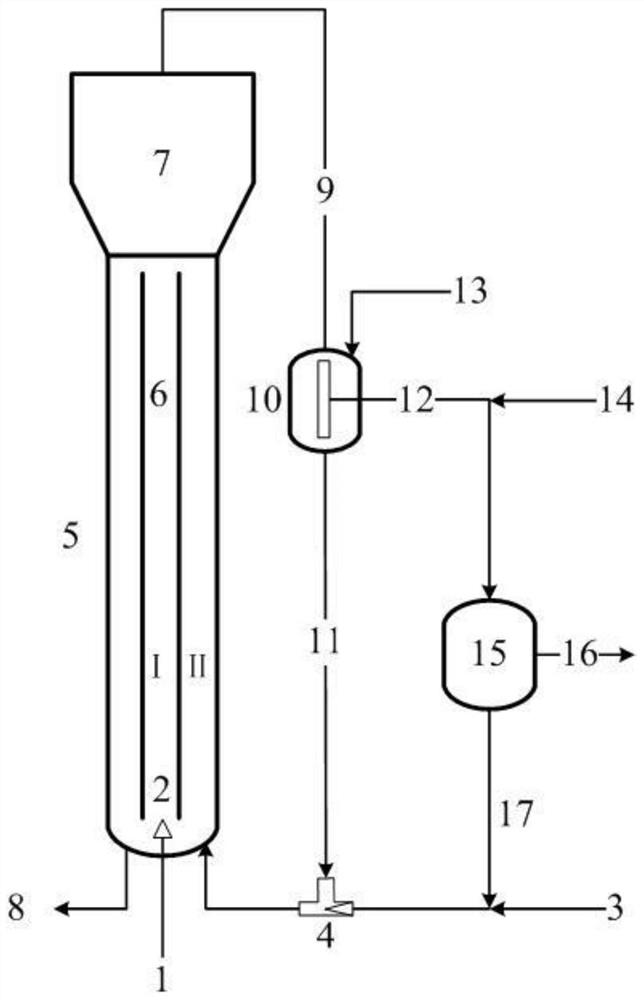

[0045] The flow process of olefin hydration reaction method is as attached figure 1 As shown, wherein, the diameter of the straight pipe section of the reactor is 48mm, and the height is 1800mm. A diversion pipe with a diameter of 25.4 mm is provided inside, and the ratio of the area of the riser zone to the downcomer zone of the straight pipe section of the reactor is 0.39. The diameter of the enlarged section of the reactor is 96mm, and the height of the enlarged section is 400mm.

[0046] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com