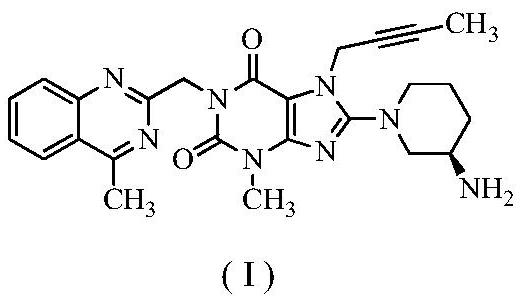

Novel preparation process of linagliptin

A preparation process, one-pot technology, applied in the production of bulk chemicals, organic chemistry, etc., can solve the problems of waste water defects, high cost, mismatched demand, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

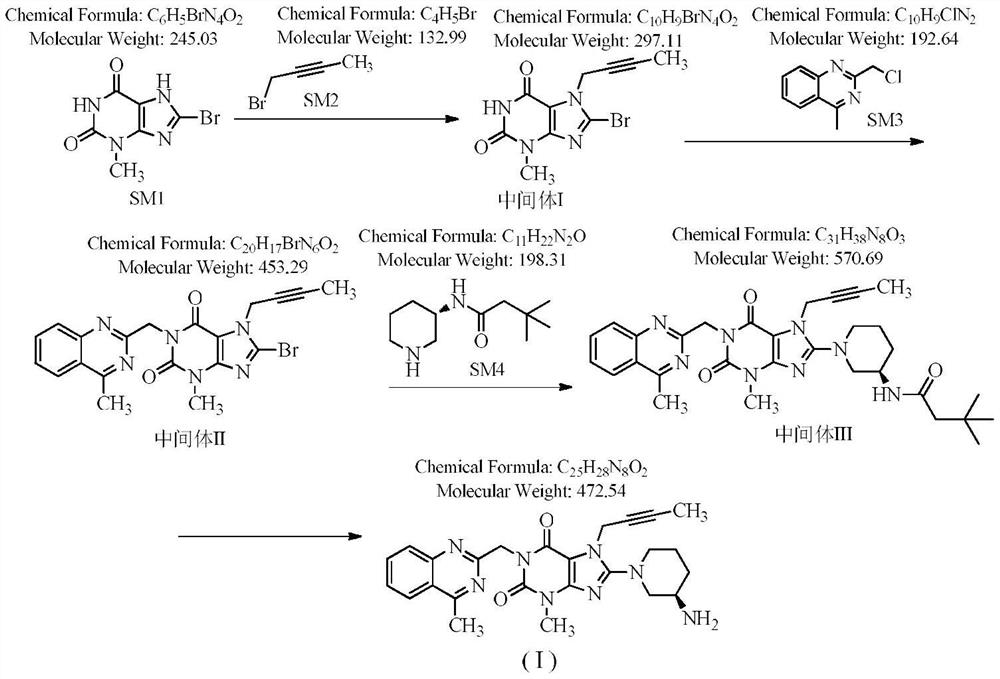

Method used

Image

Examples

Embodiment 1

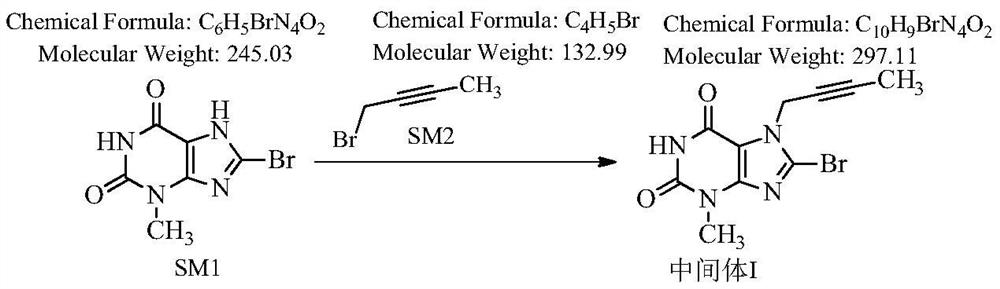

[0042] Step 1: Preparation of 8-bromo-7-(2-butyne)-3-methyl-1H-purine-2,6(3,7-dihydro)-dione

[0043] 100 g of 8-bromo-3-methylxanthine, 57 g of 1-bromo-2-butyne (1.05 equiv), 900 ml of DMF, 68.5 g of DIPEA (1.3 equiv) were added to the reaction flask. Stir at room temperature, TLC detection, complete reaction in 18 hours, and an off-white solid is obtained.

[0044] Step 2: Preparation of 8-bromo-7-(2-butyn-1-yl)-3,7-dihydro-3-methyl-1-[(4-methyl-2-quinazolinyl)methanol base]-1H-purine-2,6-dione

[0045] Add 82.5 g of 2-chloromethyl-4-methylquinazole (1.05 equivalents) to the reaction flask of the first step above, stir at 60-70° C., detect by TLC, the reaction is complete in 13 hours, and it is directly used in the next step.

[0046] Step 3: Preparation of Boc-linagliptin

[0047] After the reaction in the previous step was completed, 85 g (1.05 equivalents) of (R)-3-Boc-aminopiperidine dihydrochloride was added directly, and the reaction was stirred at 60-70° C., and th...

Embodiment 2

[0051] Different from Example 1: the catalyst triethylamine is 49.6g (1.2 equivalents), the total yield of the four-step reaction is 76.7%, and the HPLC purity is 99.73%.

Embodiment 3

[0053] Different from Example 1: the amount of DIPEA was 73.9 g (1.4 equivalents), the total yield of the four-step reaction was 78.3%, and the HPLC purity was 99.76%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com