Preparation method of temporary antirust liquid for color-coated sheet

A technology of anti-rust liquid and color-coated plate, applied in coating, anti-corrosion coating, petroleum industry and other directions, can solve the problems of unusable, poor film flexibility, easy cracking in plate processing, etc., to achieve the effect of expanding the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

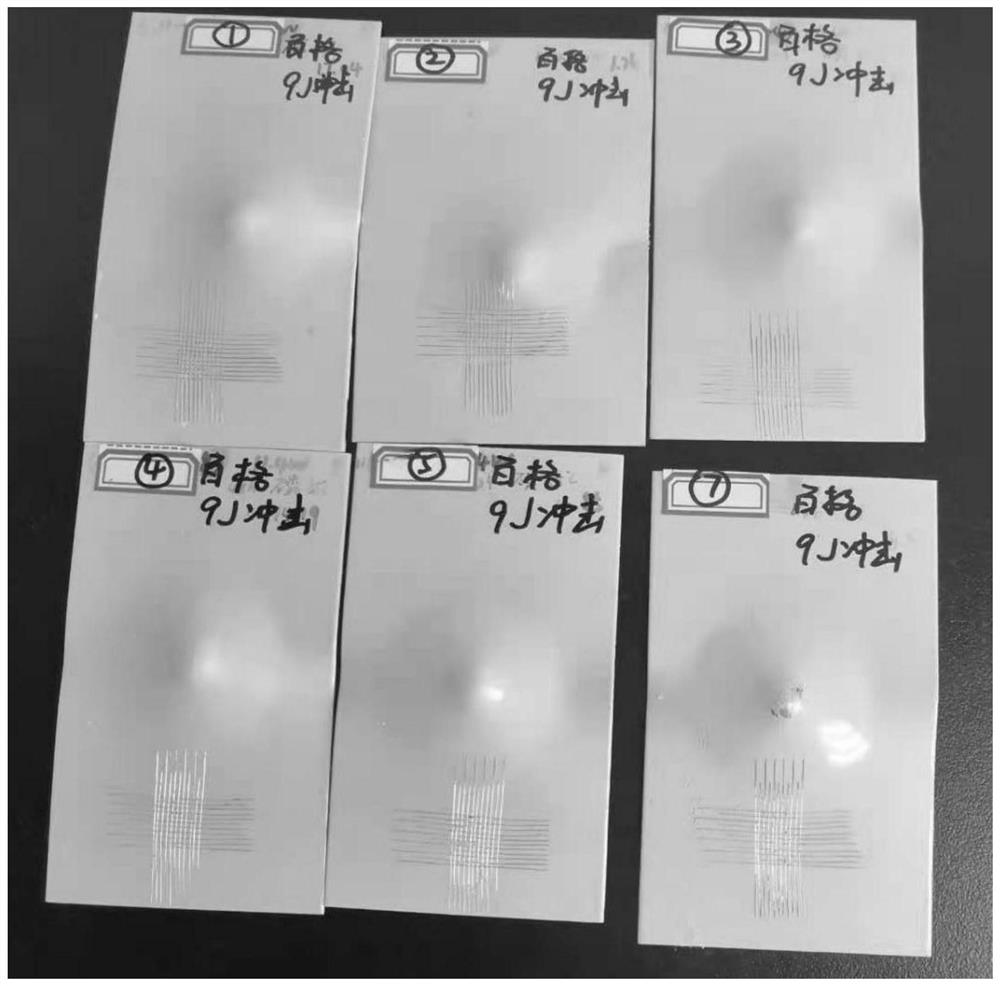

Image

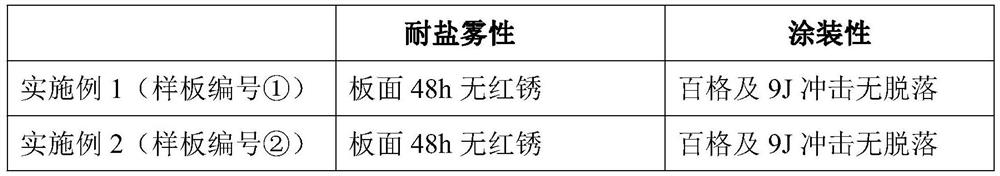

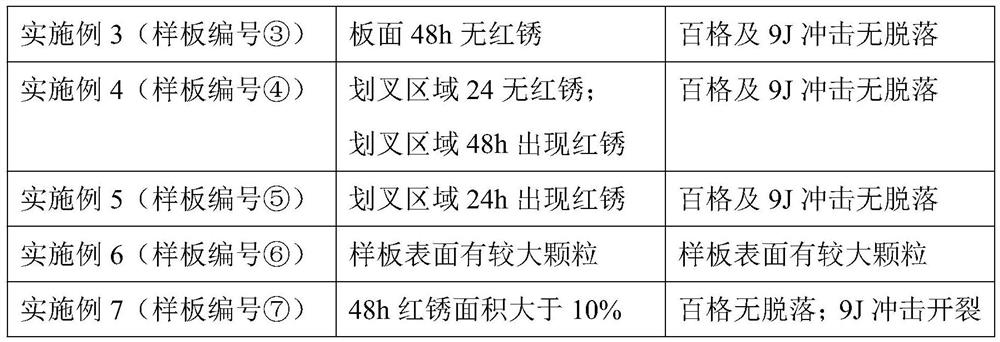

Examples

Embodiment 1

[0034] Embodiment 1 A kind of preparation method of temporary antirust liquid for prepainted plate

[0035] Every mass part is 100g in the present embodiment;

[0036] The first step: the preparation method of water-based silicone emulsion is as follows:

[0037] Step 1. Take 20 parts by mass of γ-(2,3-glycidoxy)propyltrimethoxysilane, 2 parts by mass of dodecyltrimethoxysilane and 10 parts by mass of γ-aminopropyltrimethoxysilane , mixed and stirred evenly to obtain a mixture;

[0038] Step 2. Take 80 parts by mass of deionized water and 12 parts by mass of phosphoric acid with a mass concentration of 85% and add them to the reactor, raise the temperature to 55°C, and drop all the mixture obtained in step 1 into the reactor while stirring, and the dropping time is 2h , after the dropwise addition was completed, the insulation reaction was carried out for 2 hours to obtain 124 parts by mass of water-based silicone emulsion;

[0039] Step 2: Preparation of temporary anti-rust ...

Embodiment 2

[0041] Embodiment 2 A kind of preparation method of temporary antirust liquid for prepainted board

[0042] Every mass part is 500g in the present embodiment;

[0043] The first step: the preparation method of water-based silicone emulsion is as follows:

[0044] Step 1. Take 20 parts by mass of γ-(2,3-epoxypropoxy)propyltrimethoxysilane, 3 parts by mass of octadecyltrimethoxysilane and 15 parts by mass of γ-aminopropyltriethoxysilane parts, mix and stir evenly to obtain a mixture;

[0045] Step 2. Take 80 parts by mass of deionized water and 3.8 parts by mass of nitric acid with a mass concentration of 68% and add them to the reactor, raise the temperature to 50°C, and drop all the mixture obtained in step 1 into the reactor while stirring, and the dropping time is 2h , after the dropwise addition was completed, the insulation reaction was carried out for 2 hours to obtain 128 parts by mass of water-based silicone emulsion;

[0046] Step 2: Preparation of temporary anti-ru...

Embodiment 3

[0048] Embodiment 3 A kind of preparation method of temporary anti-rust liquid for prepainted board

[0049] Every mass part is 1kg in the present embodiment;

[0050] The first step: the preparation method of water-based silicone emulsion is as follows:

[0051] Step 1. Take 35 parts by mass of γ-(2,3-epoxypropoxy)propyltriethoxysilane, 4 parts by mass of n-hexyltriethoxysilane and N-β(aminoethyl)-γ-ammonia 10 parts by mass of propyltriethoxysilane, mixed and stirred evenly to obtain a mixture;

[0052] Step 2. Take 70 parts by mass of deionized water and 2.5 parts by mass of nitric acid with a mass concentration of 68% and add them to the reactor, raise the temperature to 60°C, and drop all the mixture obtained in step 1 into the reactor while stirring, and the dropping time is 3h , after the dropwise addition was completed, the insulation reaction was carried out for 2 hours to obtain 131 parts by mass of water-based silicone emulsion;

[0053] Step 2: Preparation of tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com