Method for recovering sodium hydroxide and co-producing sodium fluoride from fluorocarbon cerium alkali transfer process

A technology for the co-production of sodium fluoride and bastnaesium alkali, applied in chemical instruments and methods, alkali metal oxides/hydroxides, alkali metal fluorides, etc., can solve environmental hazards, cannot be directly discharged, secondary Pollution and other issues, to achieve efficient recycling, avoid waste of fluorine resources, and avoid environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

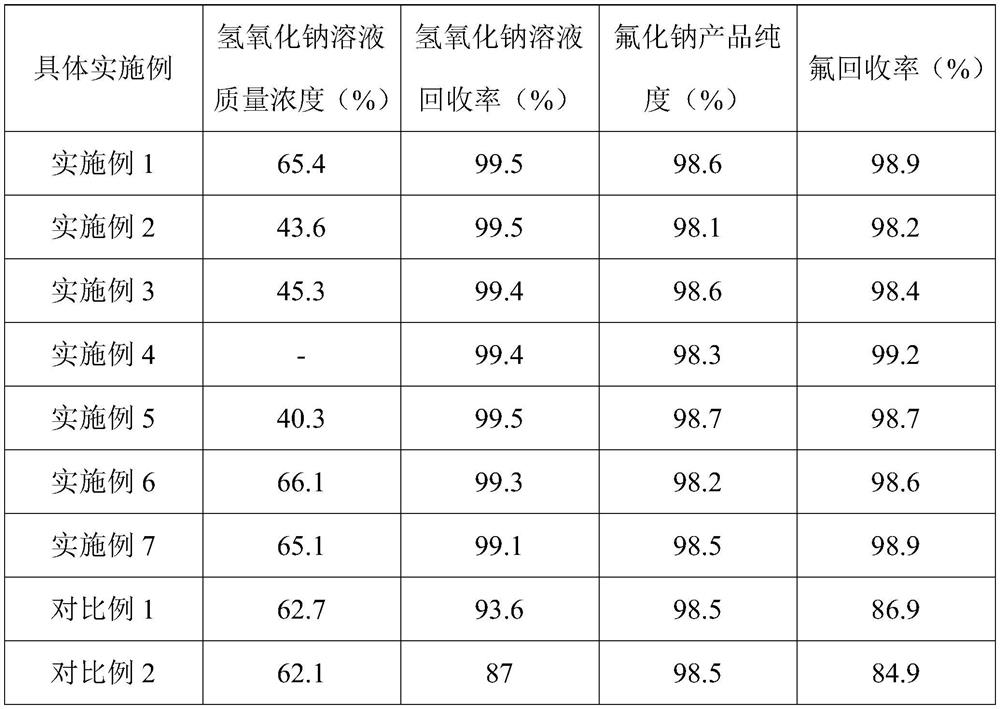

Examples

Embodiment 1

[0030] Recovery of high-quality concentration sodium hydroxide solution:

[0031] Put the rare earth fluoride acid leaching residue containing 100kg REO into the alkali transfer tank, start stirring, and after mixing evenly, add 230kg of sodium hydroxide solution with a mass concentration of 50%, start to heat up, control it at 100°C, and add a small amount during the period The specific amount of water depends on the water loss, but after the duration is 60 minutes, stop stirring, stand still for 30 minutes, transfer the supernatant to the A storage tank, then heat the water to the original liquid level, start stirring, and wash , repeated washing more than 5 times, so that the pH value of the washing liquid is 7, it is considered qualified, the washing liquid for the first 2 times is put into the A storage tank, and the washing liquid for the remaining times is put into another B storage tank for use as The water used for the first 2 washings in the next alkali conversion pr...

Embodiment 2

[0033] Recovery of low mass concentration sodium hydroxide solution:

[0034]Put the rare earth fluoride acid leaching residue containing 100kg REO into the alkali transfer tank, start stirring, and after mixing evenly, add 230kg of sodium hydroxide solution with a mass concentration of 50%, start to heat up, control it at 100°C, and add a small amount during the period The specific amount of water depends on the water loss, but after the duration is 60 minutes, stop stirring, stand still for 30 minutes, transfer the supernatant to the A storage tank, then heat the water to the original liquid level, start stirring, and wash , repeated washing more than 5 times, so that the pH value of the washing liquid is 7, it is considered qualified, the washing liquid for the first 2 times is put into the A storage tank, and the washing liquid for the remaining times is put into another B storage tank for use as The water used for the first 2 washings in the next alkali conversion process...

Embodiment 3

[0036] Recover predetermined mass concentration sodium hydroxide solution:

[0037] Put the rare earth fluoride acid leaching residue containing 100kg REO into the alkali transfer tank, start stirring, and after mixing evenly, add 230kg of sodium hydroxide solution with a mass concentration of 50%, start to heat up, control it at 100°C, and add a small amount during the period The specific amount of water depends on the water loss, but after the duration is 60 minutes, stop stirring, stand still for 30 minutes, transfer the supernatant to the A storage tank, then heat the water to the original liquid level, start stirring, and wash , repeated washing more than 5 times, so that the pH value of the washing liquid is 7, it is considered qualified, the washing liquid for the first 2 times is put into the A storage tank, and the washing liquid for the remaining times is put into another B storage tank for use as The water used for the first 2 washings in the next alkali conversion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com