Luminescent Photoelastic Coating Strain Measurement System and Method Based on Ratiometric Fluorescence Technology

A ratiometric fluorescence and strain measurement technology, applied in the field of experimental strain analysis, can solve the problems of spatial inhomogeneity, time instability of excitation light intensity, and reduced accuracy of strain analysis results, reducing equipment investment, reducing stability, The effect of improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

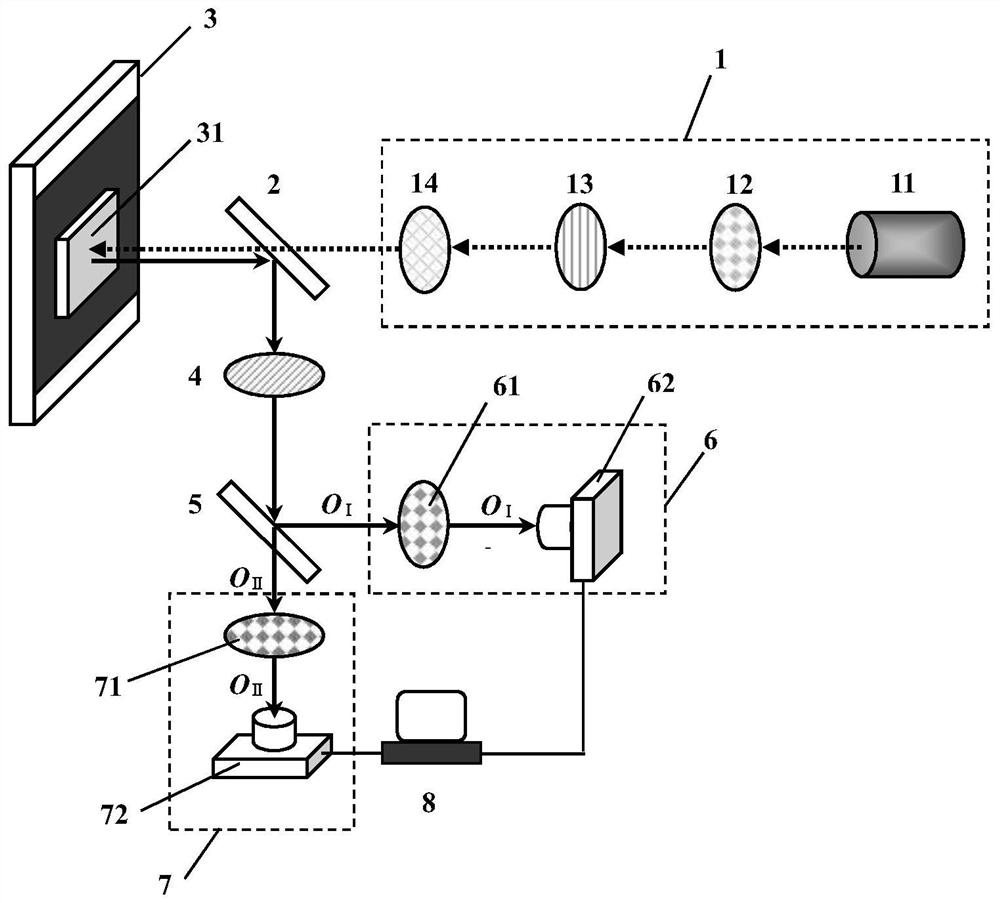

[0029] Such as figure 1 As shown, on the surface of the member 3 to be tested after the decontamination treatment, a layer of black primer layer is coated, and then on the surface of the black primer layer, a layer of luminous photoelastic coating 31 is sprayed or brushed, i.e., the light The elastic coating is added with a common excitation wavelength λ ex Two fluorescent materials: the first fluorescent material and the second fluorescent material; the light source 11 can be a laser or an LED light source, and the light wave sent by the light source 11 passes through the band-pass interference filter 12 (the central wavelength is λ ex ), the incident polarizer 13; the linearly polarized light incident quarter-wave plate 14 (its fast axis direction and the polarizing di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com