Method and system for continuously exciting crystallization

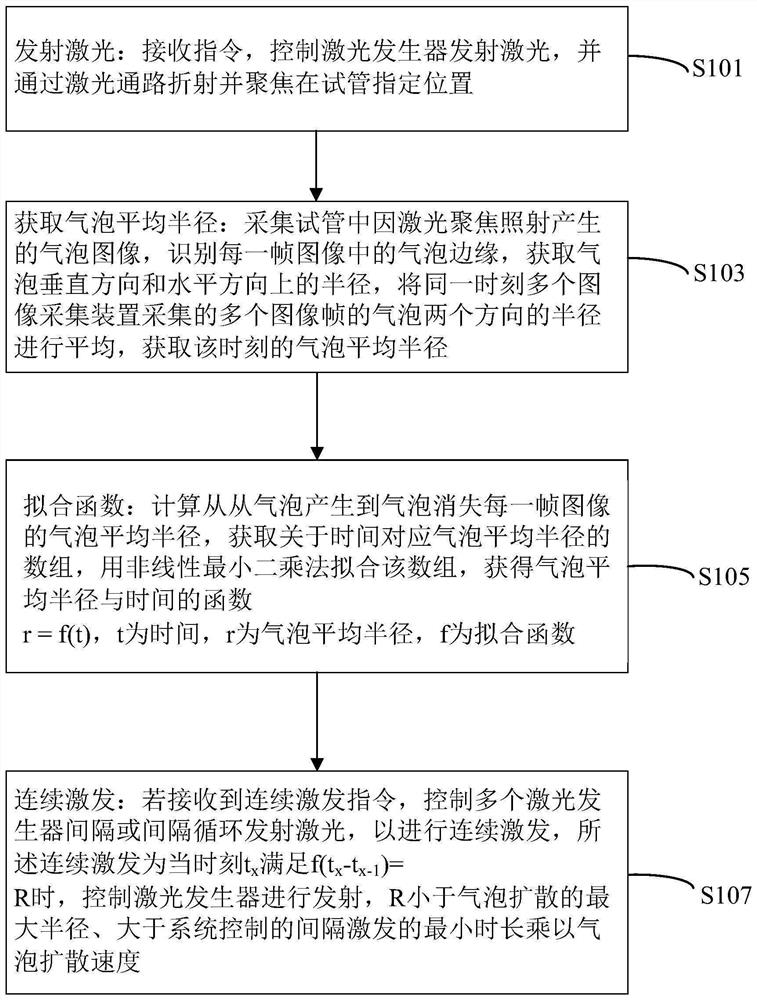

A crystallization system and crystallization technology, applied in the field of crystallization experiments, can solve the problems of short time of supersaturation, inability to create continuous increase of supersaturation, difficulty of new crystal forms, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

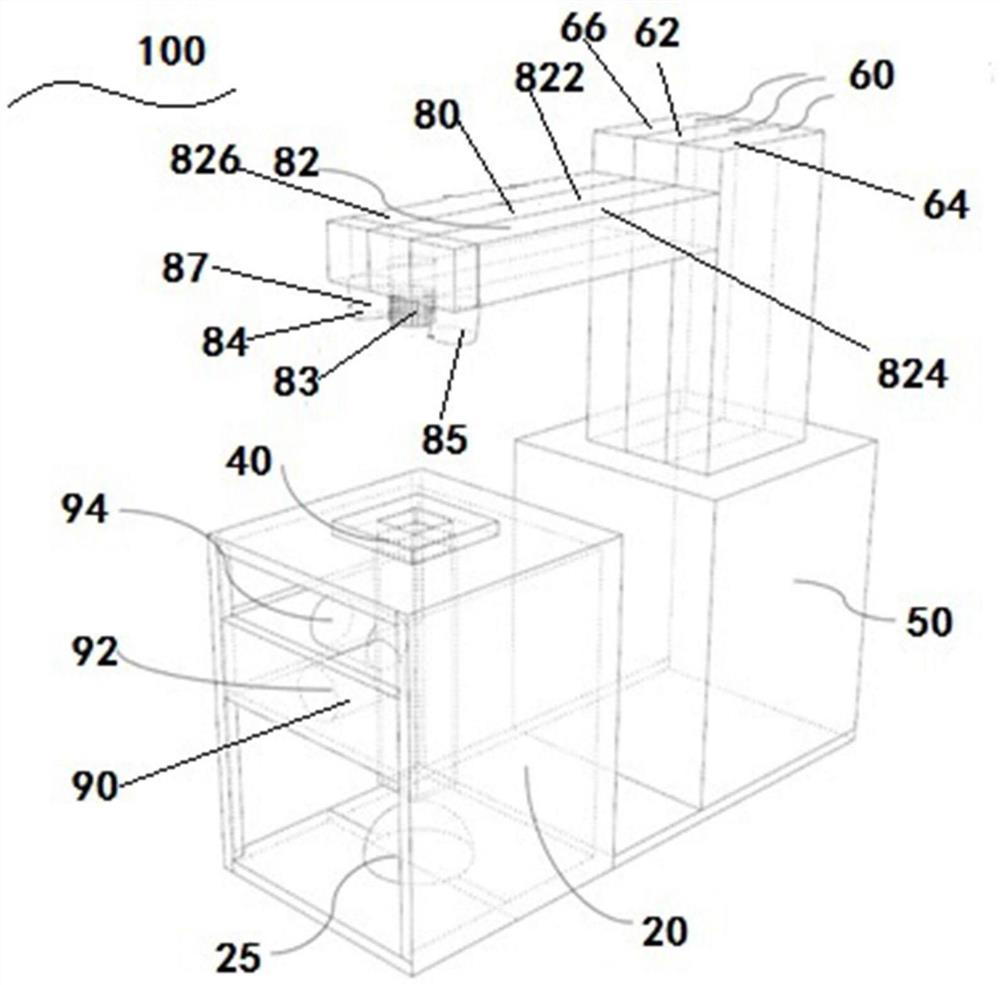

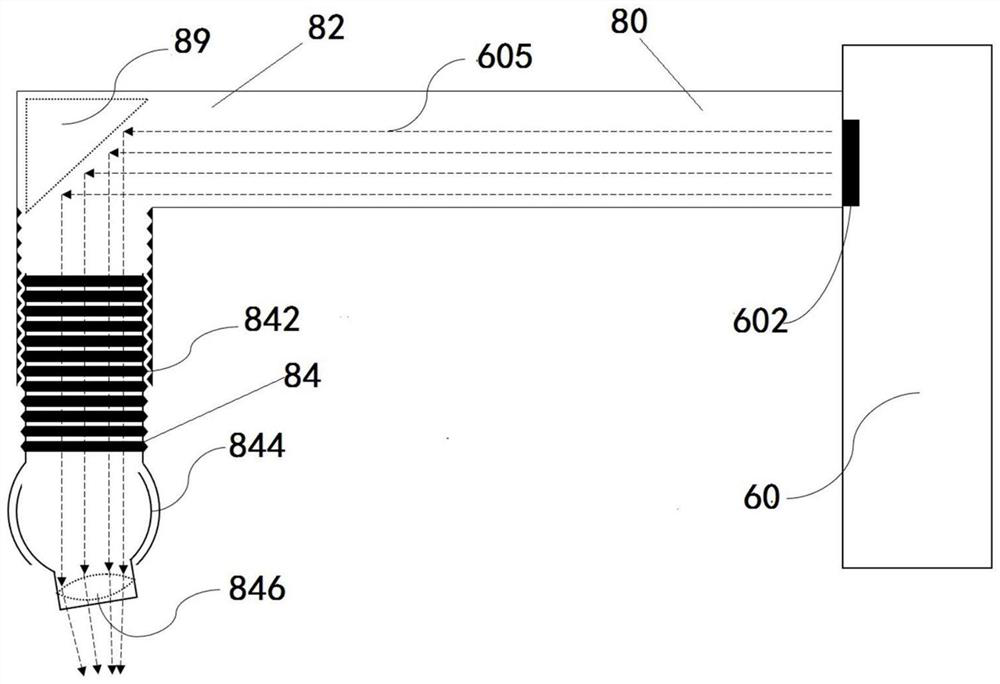

[0036]Such asFigure 1 to 2 As shown, the continuous excitation crystallization system 100 of an embodiment of the present invention includes: a test tube frame 20, a test tube 40, a plurality of controlled laser-transmitted laser generator 60, corresponding to the laser generator 60, corresponding to the laser generator 60 Set the laser light transmitted by the laser generator 60 to refractively focus on the laser passage 80 of the specified position in the test tube, disposed on the test tube frame 20 and set according to the test tube 40 and the image acquisition device 90 of the controlled collector image, and the laser generator The 60 and the image acquisition device 90 communicates and controls the respective operational control systems 50.

[0037]Since the conventional cylindrical test tube is changed from the side shot of the surface due to the curved glass, it is not possible to accurately calculate the internal image size, further, preferably, in order to ensure the quality ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com