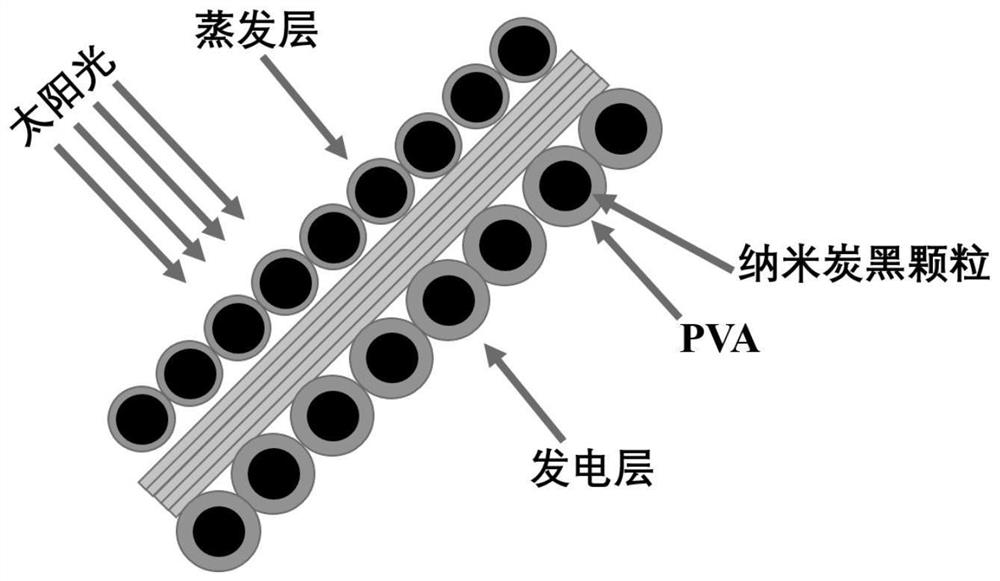

Preparation method of wood-based evaporation-hydrovoltaic cooperative power generation device with sandwich structure

A sandwich and wood-based technology, applied in the direction of electrical components, generators/motors, etc., to achieve the effects of easy material availability, increased evaporation area, and easy large-scale preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

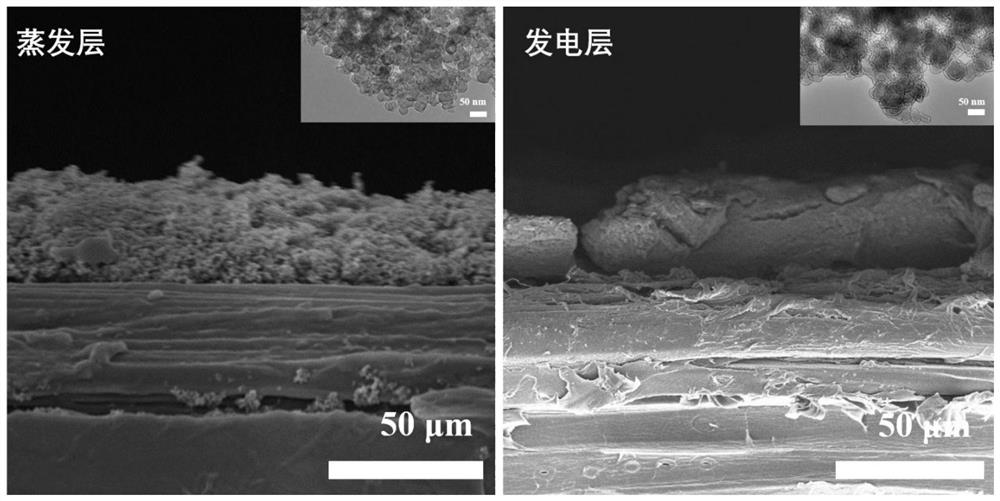

[0031] A method for preparing a wood-based evaporation-hydrovoltaic synergistic power generation device with a sandwich structure: comprising the following preparation steps:

[0032] S1, cutting the beech wood with uniform thickness into rectangular beech wood chips, washing them with absolute ethanol and deionized water for subsequent use;

[0033] S2. Use 1799 type PVA and deionized water to prepare the PVA dispersion at a concentration of 100mg / ml, and then heat the PVA dispersion in an oil bath at a temperature of 95°C for 2 hours;

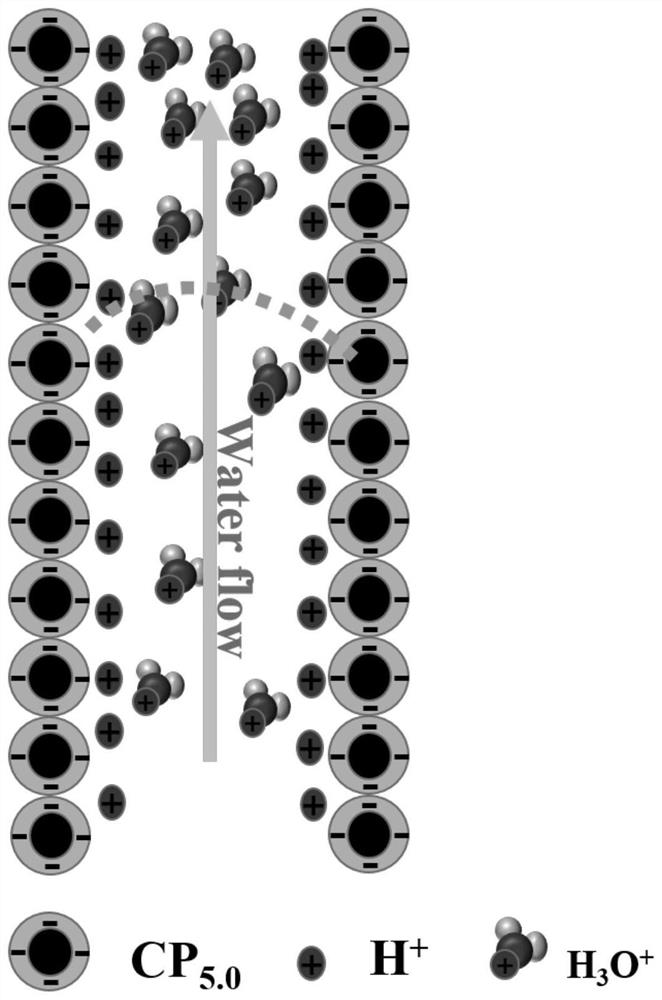

[0034] S3, use carbon black particles with an average particle diameter of 35-40nm and deionized water as a 50mg / ml proportioning carbon black particle dispersion, utilize a magnetic stirrer to stir for 15min, and then utilize a cell disruptor to carry out the carbon black particle dispersion Disperse to obtain a uniform carbon black dispersion, wherein the ultrasonic power of the cell disruptor is 450W, the diameter of the horn is 6mm, and t...

Embodiment 2

[0041] A method for preparing a wood-based evaporation-hydrovoltaic synergistic power generation device with a sandwich structure: comprising the following preparation steps:

[0042] S1. Cut the beech wood with a uniform thickness of 0.3cm into 3cm×4cm rectangular beech wood pieces, wherein the length along the wood growth direction is 4cm, first use 200mL absolute ethanol and 200mL acetone to clean, and then use 200mL deionized water to wash and set aside;

[0043] S2. Use 1799 type PVA and deionized water to mix 100ml of PVA dispersion at a concentration of 100mg / ml, and then heat the PVA dispersion in an oil bath at a temperature of 95°C for 2 hours;

[0044] S3, use carbon black particles with an average particle size of 20-35nm and deionized water to form a 50ml carbon black particle dispersion according to the concentration of 50mg / ml, stir with a magnetic stirrer for 15min, and then use a cell disruptor to crush the carbon black particle dispersion Disperse to obtain a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com