Food-grade temperature-sensitive Pickering emulsion and preparation method thereof

A Pickering emulsion, food-grade technology, used in food ingredients as emulsifiers, food forming, food science, etc., can solve the problems of limited temperature sensitive range, unable to meet the needs of release, etc., to improve emulsification activity, change Stability, hydrophobicity enhancement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Accurately weigh 30 g of waxy cornstarch, place it in a 250 mL round bottom flask, add 150 mL (3.16 mol / L) of H 2 SO 4 The solution is hydrolyzed, stirred at 400 r / min, the reaction temperature is 40° C., and the reaction time is 5 days. After the reaction, the obtained product was repeatedly washed and centrifuged until the pH of the supernatant was about 6.8, and the obtained waxy cornstarch crystal solution was freeze-dried to obtain a powder, which was stored at room temperature for later use.

Embodiment 2

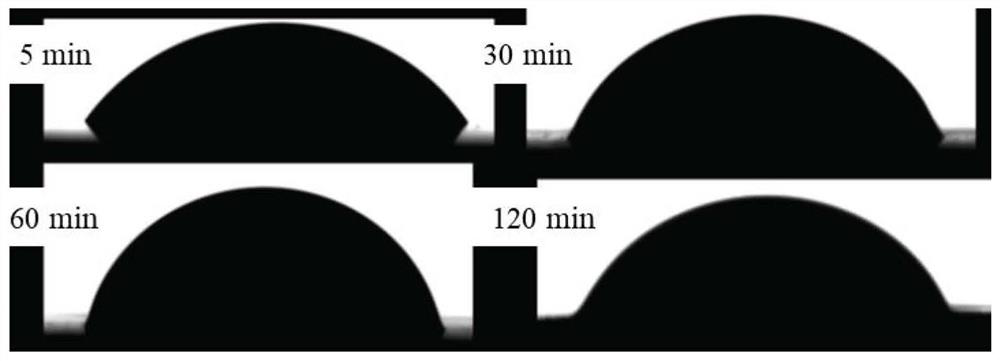

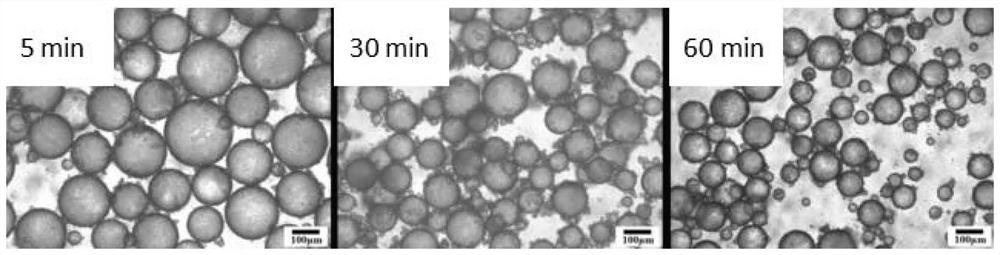

[0032] Reactor such as figure 1 As shown, first close the valve, measure 30mL of deionized water into the three-necked flask, then add 10g of carnauba wax, pass in circulating water with a temperature of 85±1°C, and start stirring. Stir for a period of time until the solid carnauba wax is completely dissolved, stop stirring, and at this moment, the upper and lower oil and water are separated, and the valve is opened to remove the lower water phase. Accurately weigh 5g of the waxy cornstarch nanocrystals in Example 1 and add them to a three-necked flask, stir at a speed of 80r / min, after stirring for 5, 30, 60 and 120min, reduce the speed, add 30mL, and the temperature is 85±1°C Put the water into the three-necked flask, continue to stir for 5 seconds, then stop stirring, open the valve, and quickly separate the starch water dispersion in the lower layer into a beaker placed in an ice-water bath. The prepared starch nanocrystal aqueous dispersion was centrifuged at 3500r / min f...

Embodiment 3

[0035] Get potato starch nanocrystal 5g, adopt the operation in embodiment 2 to carry out physical hydrophobic modification with paraffin (No. 52), and select 60min as modification time, obtain paraffin wax modified potato starch nanocrystal.

[0036]The prepared paraffin-modified potato starch nanocrystals were prepared with deionized water to prepare 25 g of a solution with a concentration of 1%, ultrasonically dispersed for 0.5 h, and left to stand for 24 h. Citral was selected as the representative flavor component, and 10 g of limonene was taken, stirred evenly with the modified waxy cornstarch nanocrystals, and the Pickering emulsion was prepared by high-speed dispersion and high-pressure homogenization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com