Atmosphere purification method and system

A purification system and atmosphere technology, applied in additive manufacturing, additive processing, etc., can solve the problems of easy combustion or explosion, high chemical activity and residual energy, danger, etc., to prevent explosion risks, prevent oxidation, and improve service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Further set forth by the following specific examples;

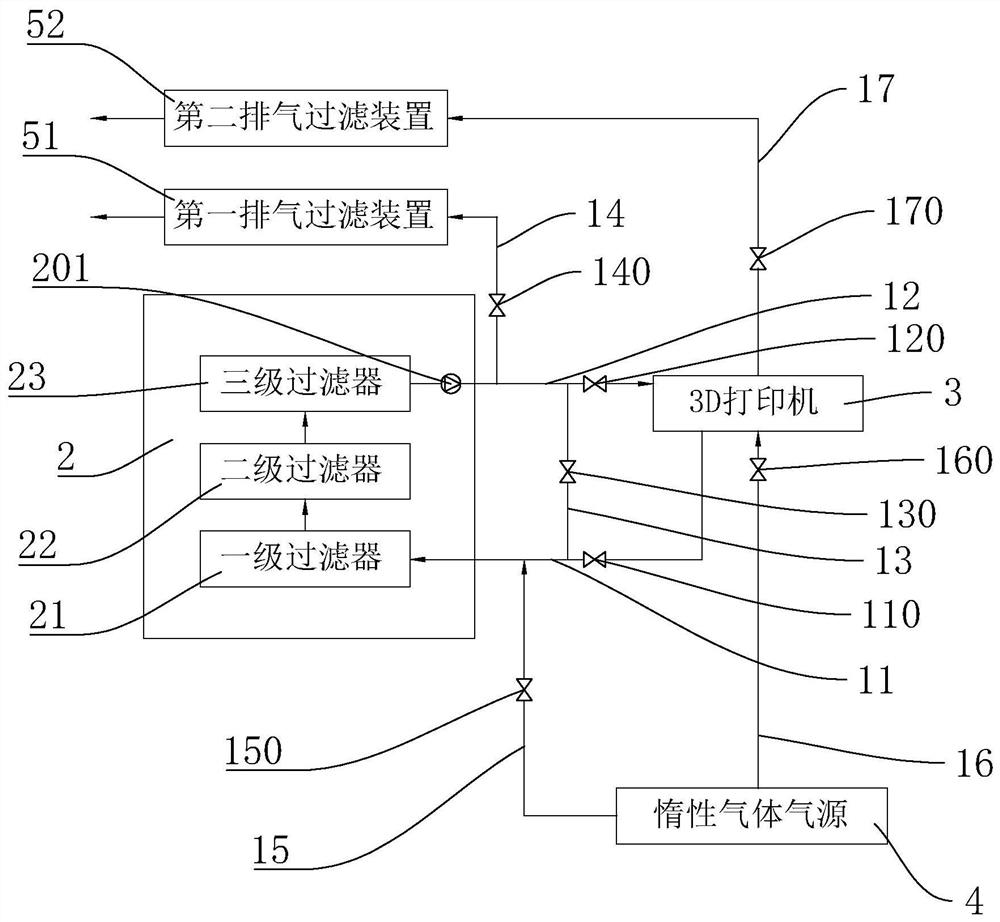

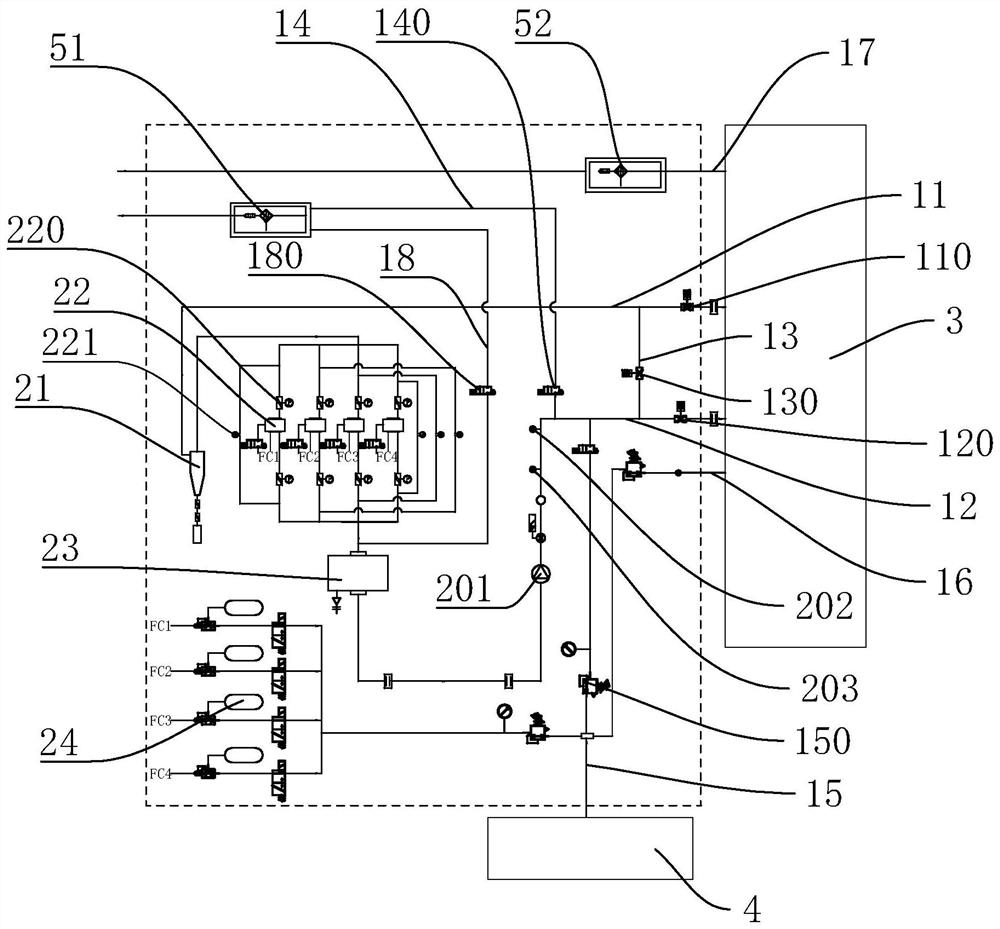

[0031] like figure 1 and figure 2 As shown, an atmosphere purification system includes a filter assembly 2, the filter assembly 2 is connected to the 3D printer 3 through an air suction pipeline 11 and an air blow pipeline 12 to form a dust removal cycle loop, and the connection between the suction pipeline 11 and the 3D printer 3 An air suction control valve 110 is provided at the end, and an air blow control valve 120 is provided at the connecting end of the air blowing pipeline 12 and the 3D printer 3. The air suction pipeline 11 and the air blowing pipeline 12 are connected through a connecting pipeline 13, and the filter assembly 2 Connect the inert gas source 4 through the intake pipeline 15, and the connecting pipeline 13 is provided with a connecting pipeline control valve 130.

[0032] The air circulation filter is used as the dust removal auxiliary device of the metal 3D printing equipment to quickly t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com