Steelmaking slag conveying production line and control system thereof

A production line and slag technology, applied in the general control system, conveyor control device, control/regulation system, etc., can solve the problems that cannot meet the requirements of slag particle size, cannot guarantee the slag batching ratio, and slag is easy to jam. Work efficiently, ensure quality stability, and have a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0095]Embodiments of the technical solution of the present invention will be described in detail below with reference to the accompanying drawings. The following examples are for more clearly illustrative of the technical solutions of the present invention, and therefore only examples are as follows, and without limiting the scope of the invention.

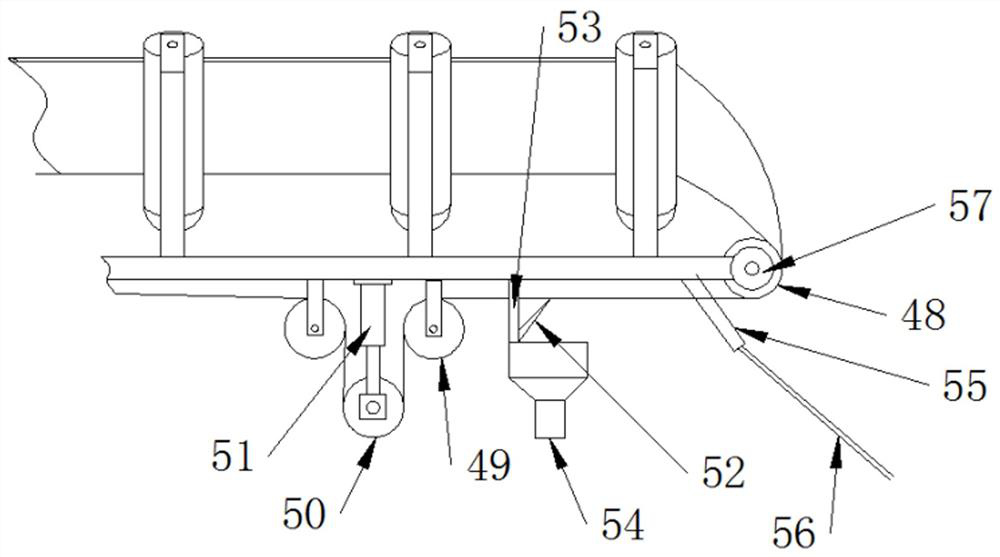

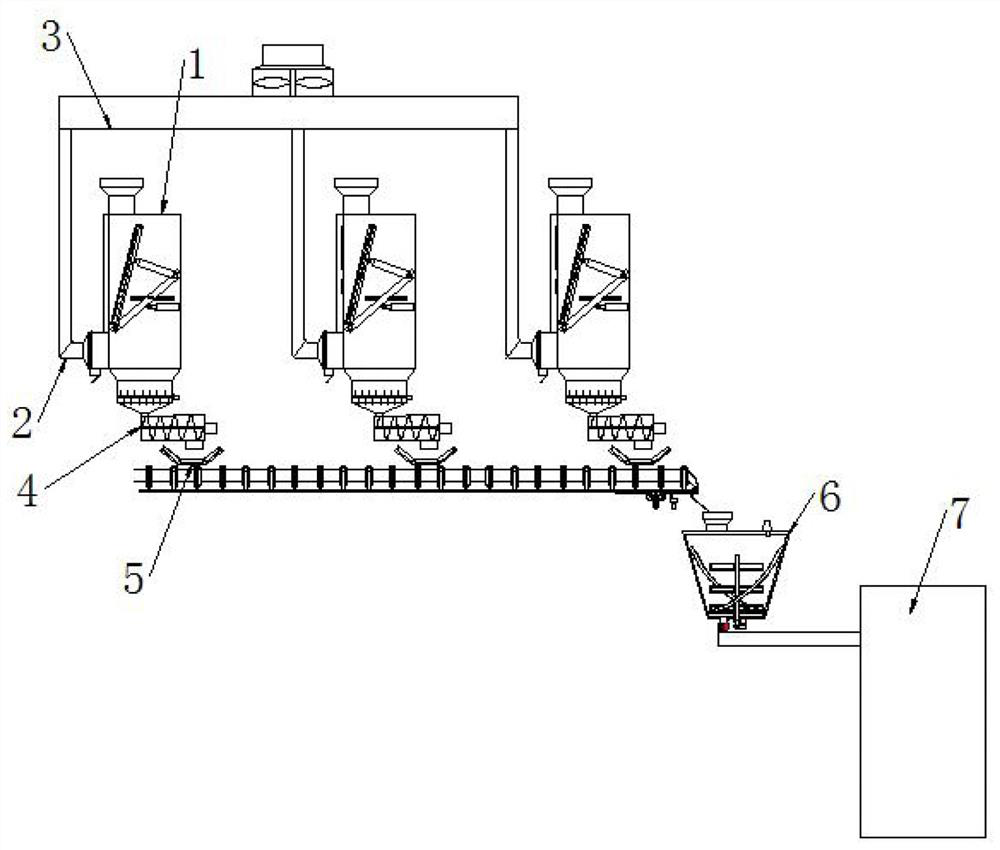

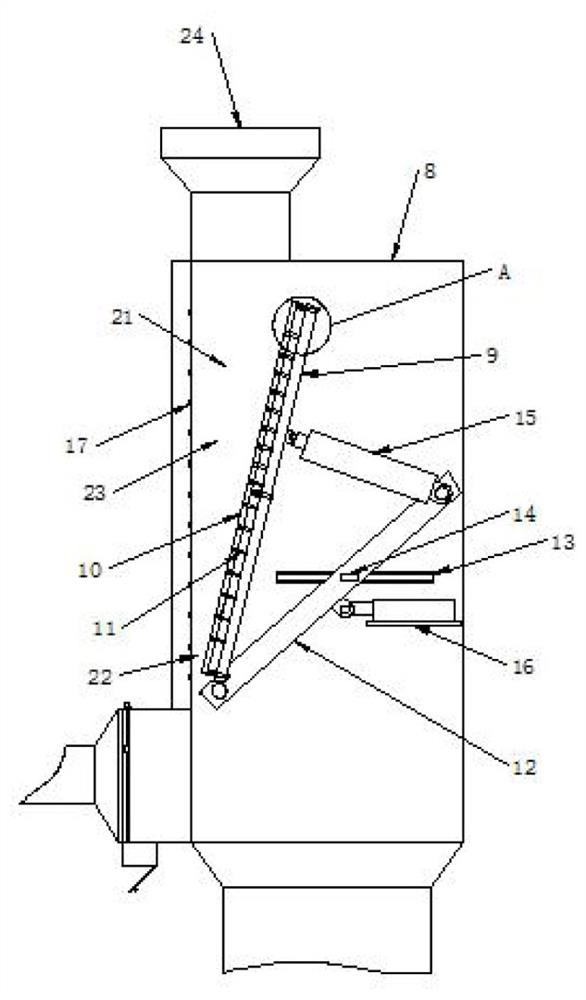

[0096]Such asFigure 1 to 11 As shown, the steelmaking slag delivery production line includes a plurality of raw material main delivery devices 1 provided in parallel, each of which is provided with a dust transport device 2, and several dust delivery devices 2 are commonly connected to the venting conveying pipe 3. On the upper, each raw material main conveying device 1 is connected to the material quantification conveying device 4, and the outlet of several material quantitative conveying device 4 is commonly connected to the assembled delivery device 5, and the assembly conveying device 5 is connected to the raw material sub-transport de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com