Plastic scintillator sheet, preparation method and preparation device thereof

A plastic scintillator and preparation device technology, which is applied in the field of nuclear radiation detection material preparation, can solve the problems of small size, poor thickness uniformity, and poor detection efficiency consistency, and achieve stable performance, good thickness uniformity, and high luminous output. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

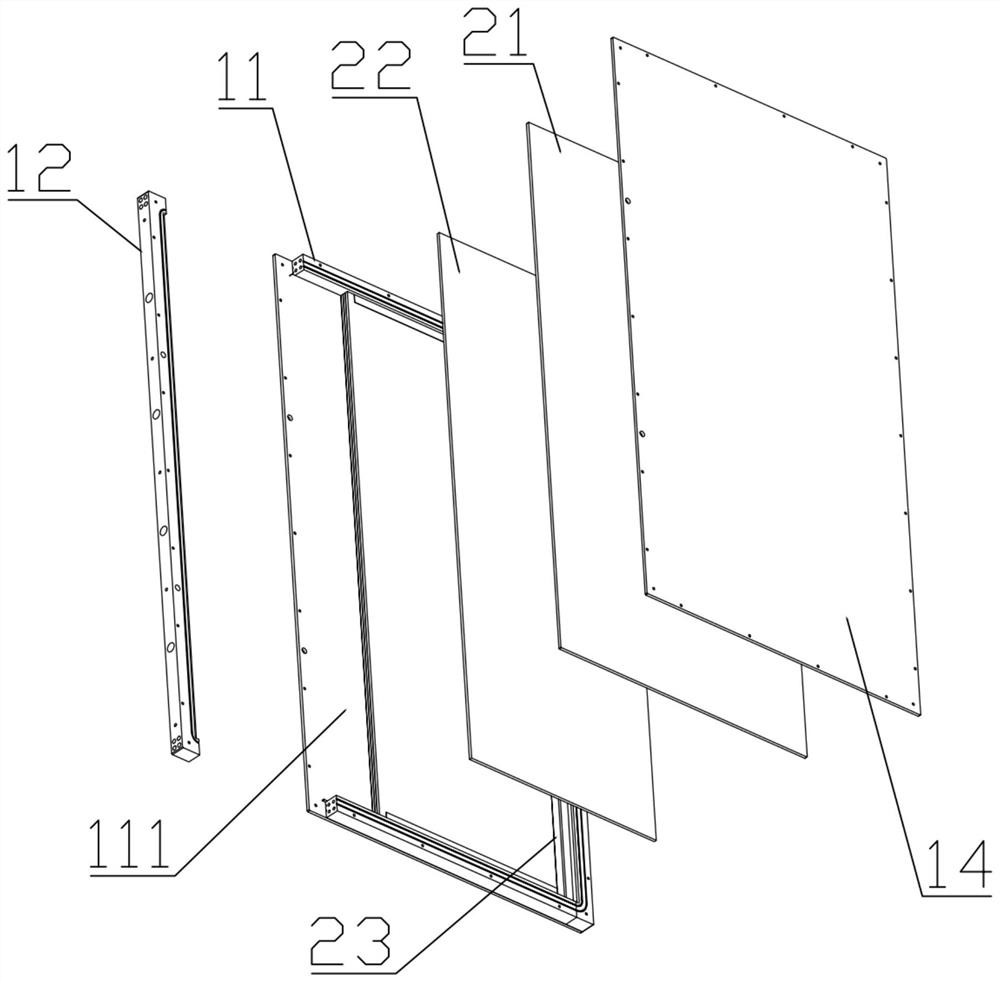

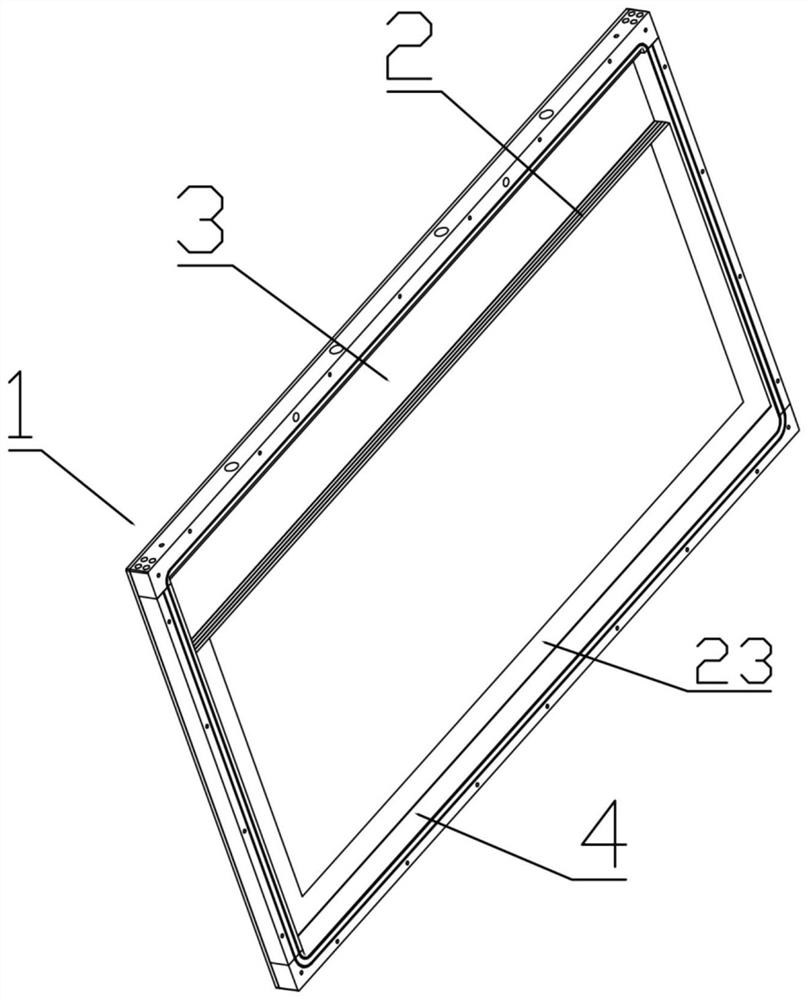

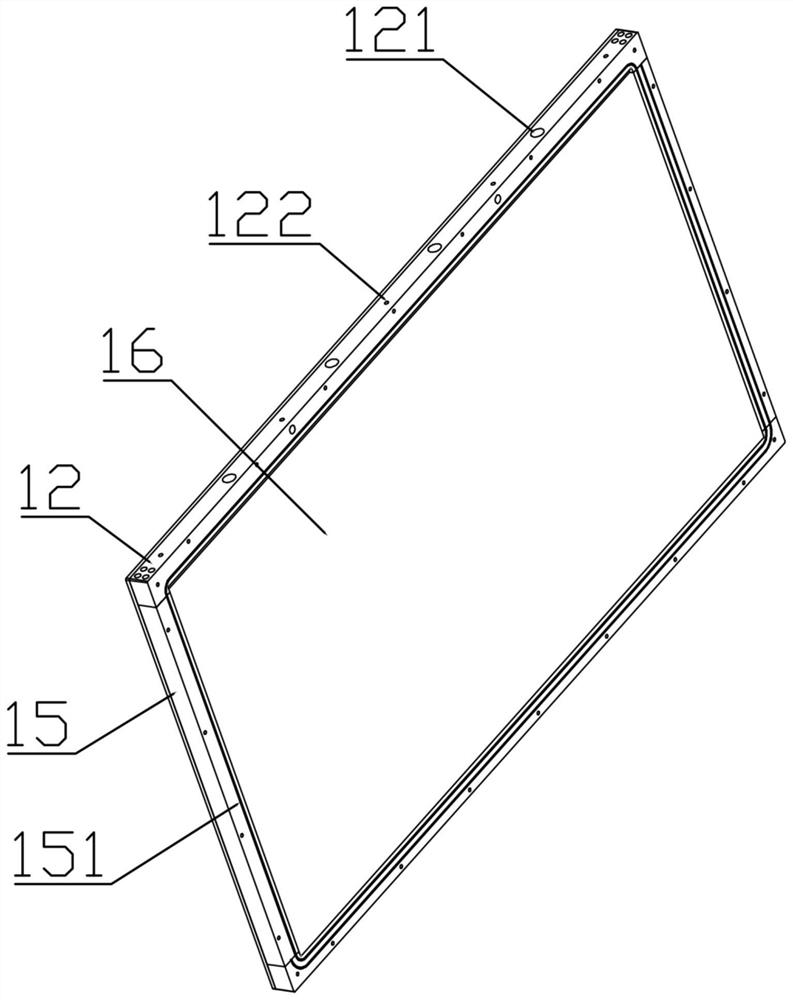

preparation example Construction

[0045] The present invention prepares the preparation method of this plastic scintillator sheet, and this preparation method comprises the following steps:

[0046] S1 Assemble and clean the preparation device, assemble the preparation device to form a reaction kettle; and clean the preparation device according to the following sequence, acetone solution cleaning → pure water cleaning → acetone solution cleaning → three times of pure water cleaning, and then dry the preparation device with nitrogen;

[0047] S2 Preparation device test, pressure-resistant and airtight test of the preparation device, the leakage of the airtight value is less than 0.15ml / min, and the pressure P value is 0.5MPa≤P≤0.8MPa;

[0048] S3 Purify the preparation device, put the preparation device into the heating furnace, and pass nitrogen gas into the preparation device for 3 to 5 cycles to replace the air in the preparation device and the reaction kettle, so that a nitrogen environment is formed in the ...

Embodiment 1

[0064] Prepare 10 pieces of plastic scintillator sheets with a thickness of 0.5 mm. The base material of the plastic scintillator sheets is styrene, luminescent agent p-terphenyl 3% and wave-shifting agent 1,4-bis(5-phenyloxazole)benzene 0.8 %.

[0065] Table 1 prepares 10 plastic scintillator sheet samples, refer to Figure 8 Test multiple points to obtain the average thickness (mm)

[0066] 1 2 3 4 5 6 7 8 9 10 0.503 0.508 0.509 0.493 0.502 0.490 0.507 0.501 0.495 0.511

Embodiment 2

[0068] Prepare 10 plastic scintillator sheets with a thickness of 0.35 mm. The base material of the plastic scintillator sheets is methyl methacrylate, and the luminescent agent is 5% of 2-(4-biphenyl)-5-phenyloxadiazole and Wave agent is 0.6% of 9,10-diphenylanthracene.

[0069] Table 2 prepares 10 plastic scintillator sheet samples, refer to Figure 8 Test multiple points to obtain the average thickness (mm)

[0070] 1 2 3 4 5 6 7 8 9 10 0.353 0.358 0.349 0.353 0.352 0.350 0.347 0.351 0.345 0.351

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com