Integrated high-speed polarization controller based on lithium niobate thin film and preparation method

A polarization controller, lithium niobate technology, applied in instruments, nonlinear optics, optics, etc., can solve expensive problems, and achieve the effects of low power consumption, fast response speed, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

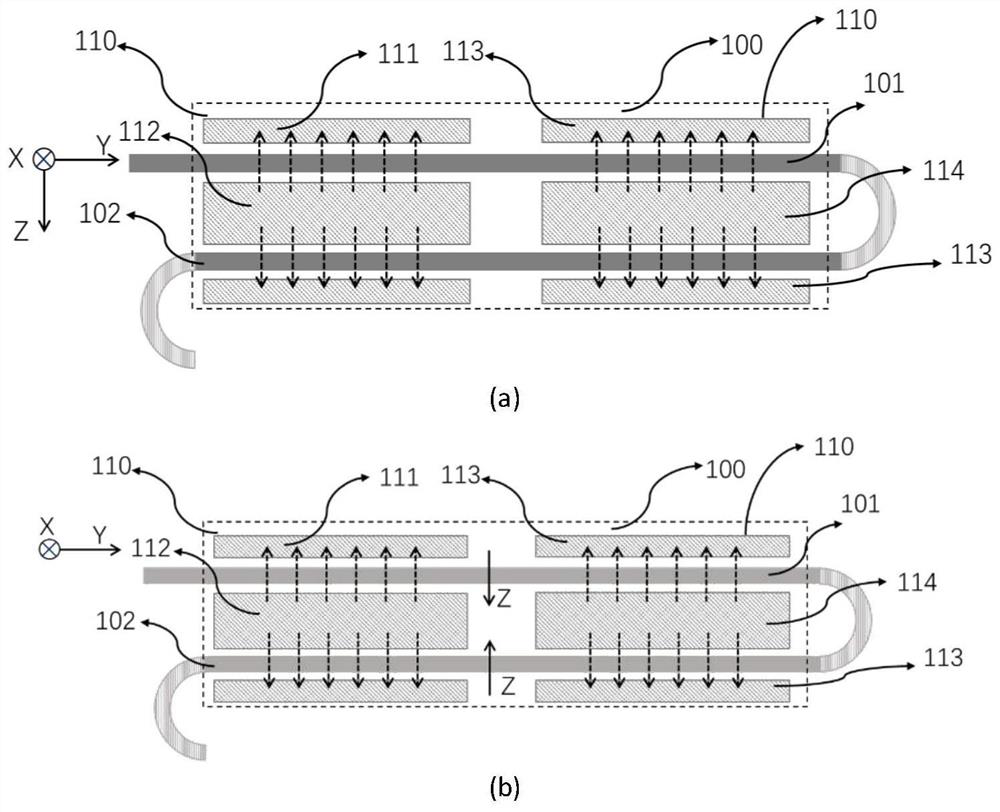

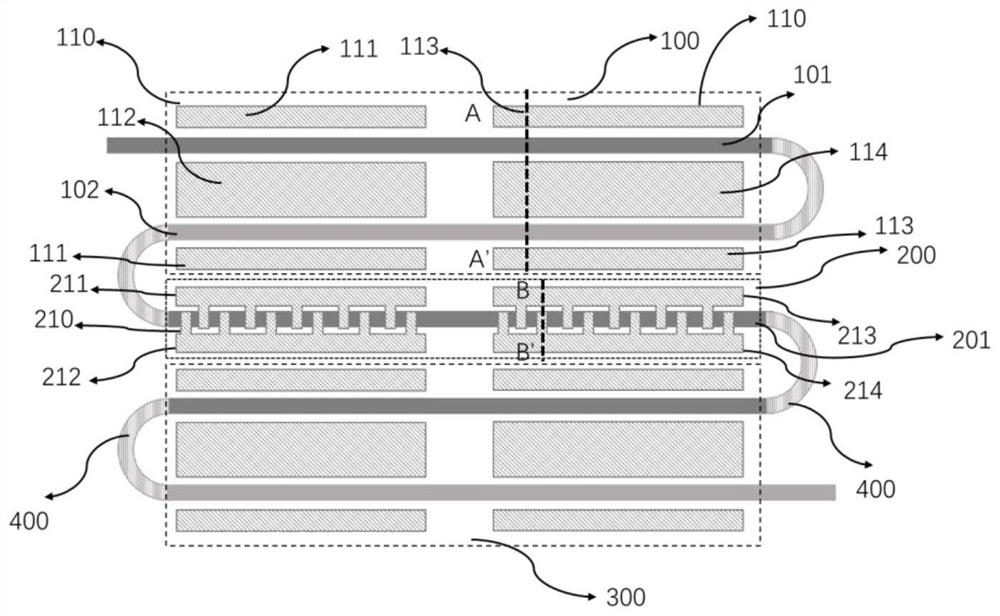

[0072] Such as image 3As shown, it is an embodiment of the present invention, the lower cladding layer 501 and the upper cladding layer 503 of the lithium niobate waveguide are made of silicon dioxide, and the substrate 502 is made of silicon. In this embodiment, the effective refractive indices of the two polarization modes TE and TM in the mode conversion region are not equal, and birefringence exists. In the first phase shifting area 100 and the second phase shifting area 300, the GSG segmented electrodes 110 of the first phase shifting area 100 are located on both sides of the lithium niobate waveguide, and the two polarization modes of TE and TM are controlled under the action of the electric field Ez The phase difference, the cross-sectional schematic diagram is shown in Figure 4 shown. In the mode conversion region 200, in order to realize the conversion of the orthogonal TE / TM mode in the lithium niobate waveguide, it is necessary to introduce off-diagonal elements...

Embodiment 2

[0074] In the lithium niobate waveguide, when the refractive indices of TE and TM are matched, that is, when there is no phase mismatch, the use of periodic electrodes or chirped electrodes can be avoided to match the refractive indices of TE and TM. The schematic diagram of the structure is as follows Image 6 shown. The electrodes in the phase-shifting region are the same as in Embodiment 1, and the electrodes in the mode-converting region can completely switch between the two modes without periodic electrodes due to the matching of TE and TM refractive index. The non-diagonal element of the electric field Ex component can not be zero, the first segment signal electrode 212 of the mode conversion segment electrode 210 of the mode conversion zone segment electrode and the second segment signal electrode 214 of the mode conversion zone segment electrode 214 are located in the lithium niobate waveguide 201 the top of.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com