High-stability grease particle product and preparation method thereof

A high-stability, grease-based technology, applied in the direction of edible oil/fat, medical preparations of non-active ingredients, microcapsules, etc., can solve problems such as poor product stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0008] First of all, the application discloses a preparation method of a high-stable fat particle product, wherein the weight of the fat and / or fat-soluble functional components accounts for more than 70% of the total weight of the product, and the preparation method includes the following steps:

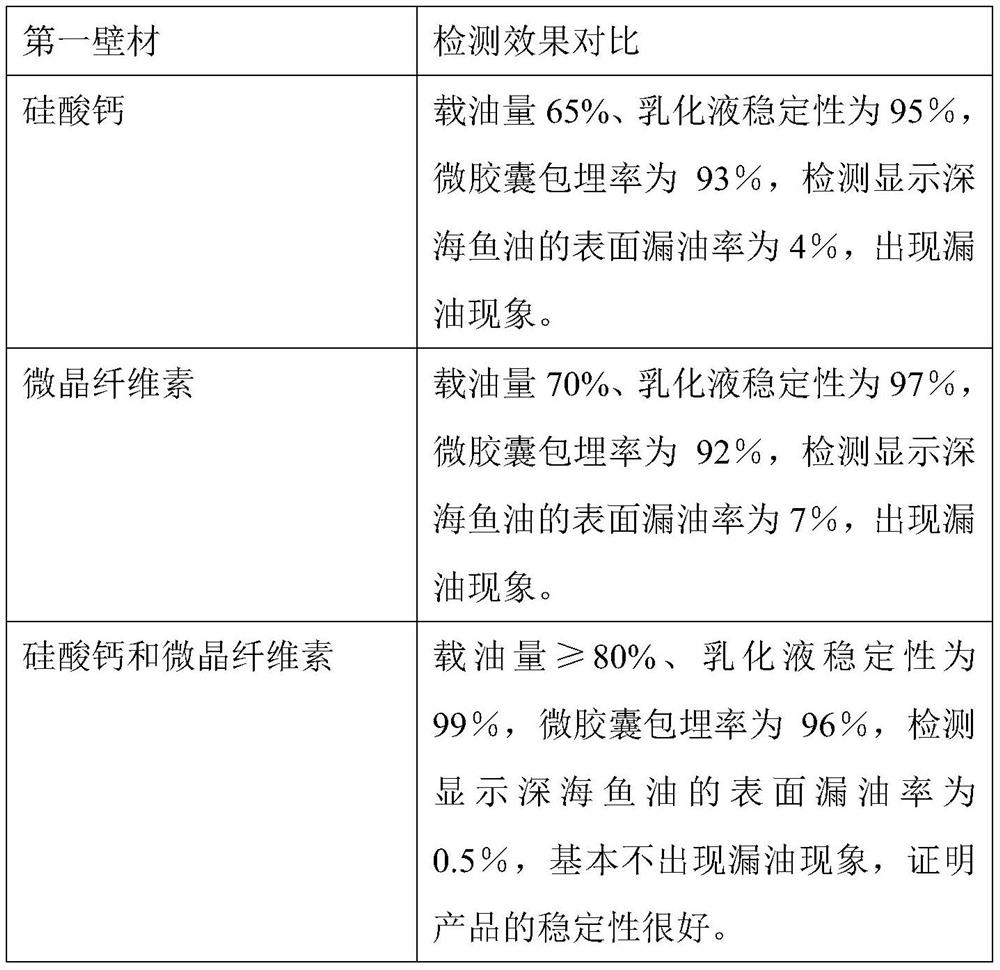

[0009] Step (1): Fully stir and mix 70-80 parts by weight of oil and / or fat-soluble functional ingredients and 1-4 parts by weight of the first wall material at 65-75° C. to obtain mixture A;

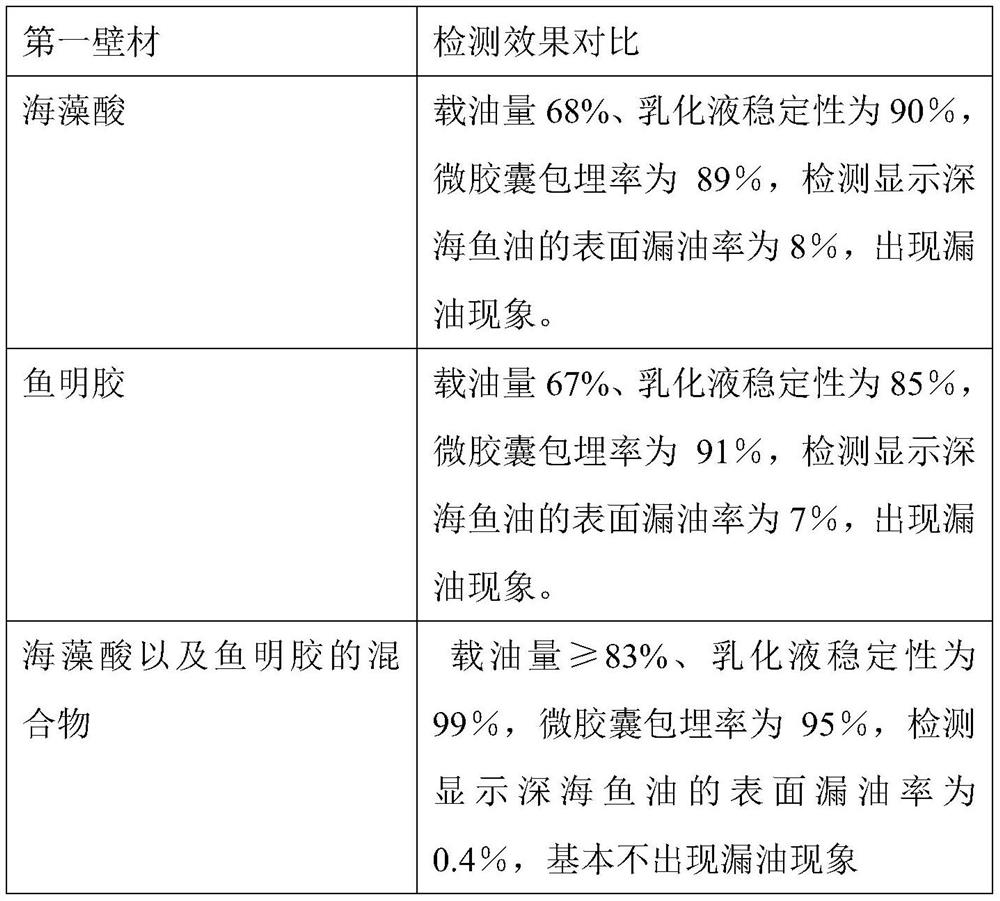

[0010] Step (2): After fully mixing 5-10 parts by weight of alginic acid and 20-30 parts by weight of gelatin, add water for sufficient hydrolysis reaction; then add 0.2-0.5 parts of glutamine transaminase for cross-linking reaction to obtain a solution B;

[0011] Step (3): Mix and stir the solution A obtained in step (1) and the solution B obtained in step (2), wherein the weight ratio of solution A to solution B is (70-80): (10-18);

[0012] Step (4): homogeneously disperse the mixture ob...

Embodiment 1

[0026] Step (1): Fully stir and mix 70 parts by weight of deep-sea fish oil and 1 part by weight of the first wall material at 65°C to obtain mixture A; the first wall material is selected from calcium silicate in equal parts by weight and microcrystalline cellulose mixture.

[0027] Step (2): After fully mixing 5 parts by weight of alginic acid and 20 parts by weight of fish gelatin, add water to carry out sufficient hydrolysis reaction; then add 0.2 parts of transglutaminase to carry out cross-linking reaction to obtain solution B;

[0028] Step (3): Mix and stir the solution A obtained in step (1) and the solution B obtained in step (2), wherein the weight ratio of solution A to solution B is 70 parts by weight: 10 parts by weight;

[0029] Step (4): The mixture obtained in step (3) is homogenized, and 4-7% of the weight of the final product granule preparation is added to disperse pharmaceutical grade calcium silicate; finally, a highly stable oil particle product is obtai...

Embodiment 2

[0038] Step (1): Fully stir and mix 80 parts by weight of deep-sea fish oil and 2 parts by weight of the first wall material at 75°C to obtain mixture A; the first wall material is selected from calcium silicate in equal parts by weight and microcrystalline cellulose mixture.

[0039] Step (2): After fully mixing 7 parts by weight of alginic acid and 30 parts by weight of fish gelatin, add water to carry out sufficient hydrolysis reaction; then add 0.5 part of transglutaminase to carry out cross-linking reaction to obtain solution B;

[0040] Step (3): Mix and stir the solution A obtained in step (1) and the solution B obtained in step (2), wherein the weight ratio of solution A to solution B is 80 parts by weight: 13 parts by weight;

[0041] Step (4): Homogenize the mixture obtained in step (3), add pharmaceutical grade calcium silicate in an amount of 4% by weight of the final product granule preparation to disperse, and finally obtain a high-stable oil particle product.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com