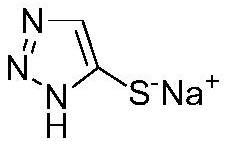

Synthesis method for preparing 5-sulfydryl-1, 2, 3-triazole sodium salt by one-pot method

A synthesis method and technology of sodium triazole are applied in the field of one-pot preparation of 5-mercapto-1, and can solve the problems of short steps, dangerous separation process and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

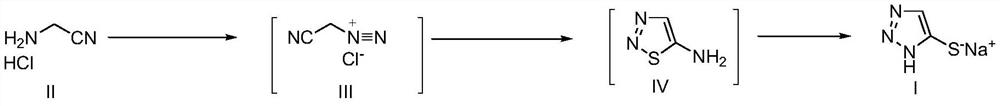

Method used

Image

Examples

Embodiment 1

[0037] In the reaction flask, add 50ml of water, 31g of aminoacetonitrile hydrochloride, stir, dissolve, add 180ml of dichloromethane, cool to -5°C-0°C, dropwise add 80g of sodium nitrite solution (37.5%), and control the dropwise Adding temperature 1 HNMR (D 2 O, 400MHz): δ7.20(s, 1H, PhH); MS, m / z: 123.99[M+H] +

Embodiment 2

[0039] In the reaction bottle, add 50ml of water, 31g of aminoacetonitrile hydrochloride 31g, stir, dissolve, add 83ml of dichloromethane, 98ml of chloroform, cool to -5°C-0°C, dropwise add 80g of sodium nitrite solution ( 37.5%), control the dropwise addition temperature1 HNMR (D 2 O, 400MHz): δ7.20(s, 1H, PhH); MS, m / z: 123.99[M+H] +

Embodiment 3

[0041]In the reaction flask, add 50ml of water, 31g of aminoacetonitrile hydrochloride, stir, dissolve, add 83ml of dichloromethane, 98ml of chloroform, cool to -5°C-0°C, dropwise add 80g of sodium nitrite solution (37.55 ), control the dropwise addition temperature1 HNMR (D 2 O, 400MHz): δ7.20(s, 1H, PhH); MS, m / z: 123.99[M+H] +

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com