Water-based gravure ink for BOPP film inner printing and preparation method thereof

A gravure ink, water-based technology, applied in the field of water-based gravure ink and its preparation, can solve the problems of low production and use costs, environmental pollution, etc., achieve fast drying speed, reduce the risk of safety accidents, and good compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

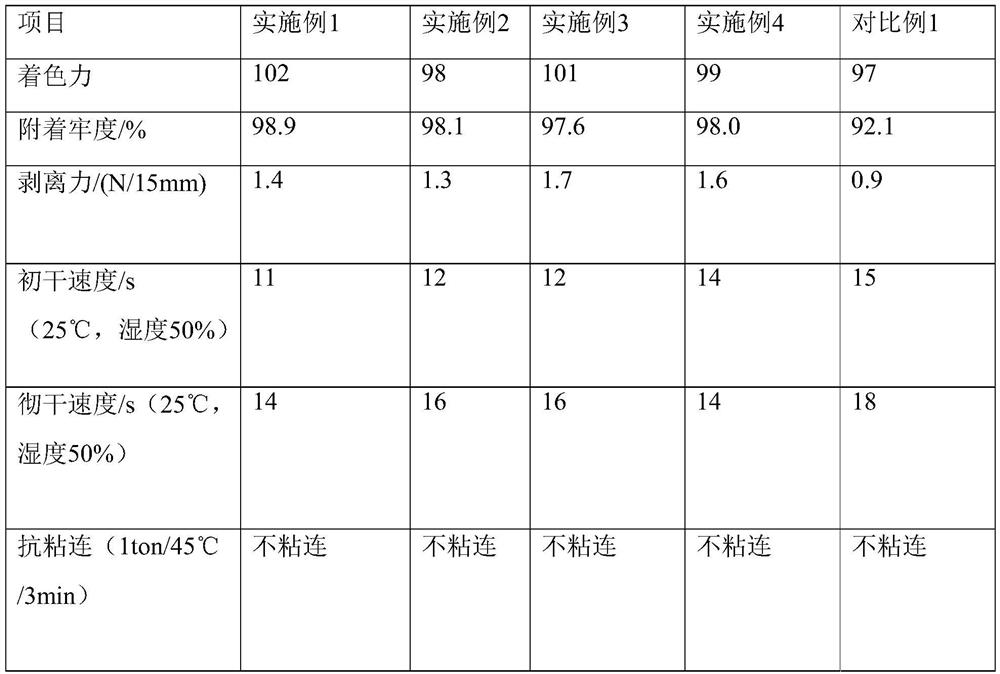

Examples

preparation example Construction

[0029] In one embodiment of the present invention, a kind of preparation method of the above-mentioned water-based gravure ink that is used for BOPP film inner printing comprises the steps:

[0030](1), after stirring and mixing the raw materials in the composite intermediate in proportion, grinding to a fineness of ≤20 μm to obtain the composite intermediate;

[0031] (2) Mix quick-drying modified acrylic resin liquid, water-based polyurethane dispersion, matte powder, deionized water, absolute ethanol, defoamer and composite intermediate in proportion, and stir evenly to prepare BOPP Water-based gravure ink printed on film.

Embodiment 1

[0033] A water-based gravure ink used for back printing of BOPP films, comprising the following raw materials in parts by weight: 18 parts of quick-drying modified acrylic resin liquid, 10 parts of water-based polyurethane dispersion, 1 part of matte powder, 8 parts of deionized water, 7 parts of absolute ethanol, 40 parts of composite intermediate, and 0.08 parts of defoamer.

[0034] Further, each part of the composite intermediate includes the following raw materials by weight: 30 parts of quick-drying modified acrylic resin liquid, 20 parts of pigment, 0.2 part of defoamer, 18 parts of deionized water, 18 parts of absolute ethanol, 15 parts of nano calcium carbonate.

[0035] Further, the particle size of the nano-calcium carbonate is 30-60 nm.

[0036] Further, the aqueous polyurethane dispersion is Joncryl FLX5201. The quick-drying modified acrylic resin liquid is Li Jiaqiao RT5313 resin liquid.

[0037] Further, the matte powder is precipitated silica. The average p...

Embodiment 2

[0043] A water-based gravure ink used for back printing of BOPP films, comprising the following raw materials in parts by weight: 10 parts of quick-drying modified acrylic resin liquid, 5 parts of water-based polyurethane dispersion, 0.5 parts of matte powder, 5 parts of deionized water, 5 parts of absolute ethanol, 30 parts of composite intermediate, 0.05 part of defoamer.

[0044] Further, each part of the composite intermediate includes the following raw materials by weight: 20 parts of quick-drying modified acrylic resin liquid, 15 parts of pigment, 0.1 part of defoamer, 15 parts of deionized water, 15 parts of absolute ethanol, 10 parts of nano calcium carbonate.

[0045] Further, the defoamer is organically modified silicone emulsion, which does not contain VOCs.

[0046] A kind of preparation method of the above-mentioned water-based gravure ink that is used for printing in BOPP film comprises the steps:

[0047] (1), after stirring and mixing the raw materials in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com