Zanthoxylum armatum oil production equipment

A production equipment and rattan pepper oil technology, applied in the direction of fat oil/fat production, fat production, food science, etc., can solve the problems of raw taste, short extraction time, high oil temperature requirements, etc., to achieve convenient and quick operation, high extraction efficiency, Process low energy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

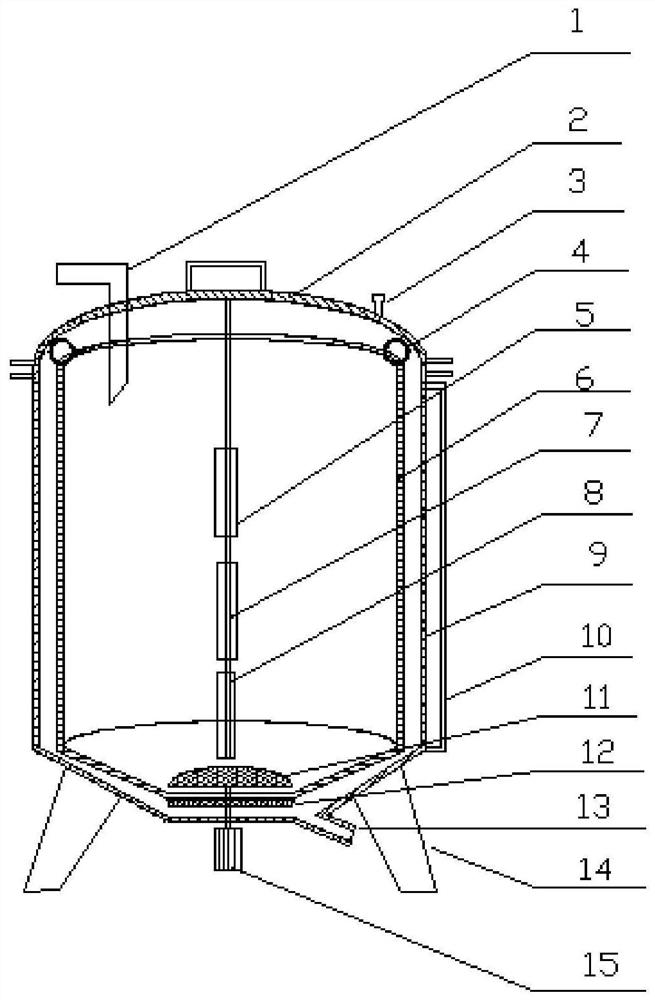

[0029] Embodiment 2, on the basis of Embodiment 1, also includes an inner barrel 6; the inner barrel 6 is arranged in the barrel body 9; the inner barrel 6 is a container provided with a sieve mesh; the bottom of the inner barrel 6 is connected with a stirring device, The materials in the inner barrel 6 are stirred by the stirring device and the inner barrel 6 is driven to rotate centrifugally.

[0030] The upper end of the inner barrel 6 is provided with a pull ring 4 .

[0031] Described stirring device comprises motor 15, power converter 12 and disk type stirrer 11; Described inner tub 6 is arranged on the power converter 12; The output end of described motor 15 is connected with power converter 12 and disc type stirrer 11 .

[0032] In the step of embodiment 1, after opening the pipeline valve of the oil outlet 13 and transferring the extracted rattan pepper oil, the power converter 12 in the stirring device is operated to make the inner barrel 6 rotate at a high speed fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com