Shield tunnel prefabricated mid-partition mounting device

An installation device and shield tunneling technology, applied in the direction of tunnels, tunnel linings, shaft equipment, etc., can solve the problem of changing the stress and deformation mode of the tunnel segment structure design, requiring high construction skills for workers, and increasing the size of the tunnel pipe The problems such as the connection stiffness between the sheets can be solved, so as to achieve the effect of strong controllability in the construction process, improvement of construction quality, and improvement of construction quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

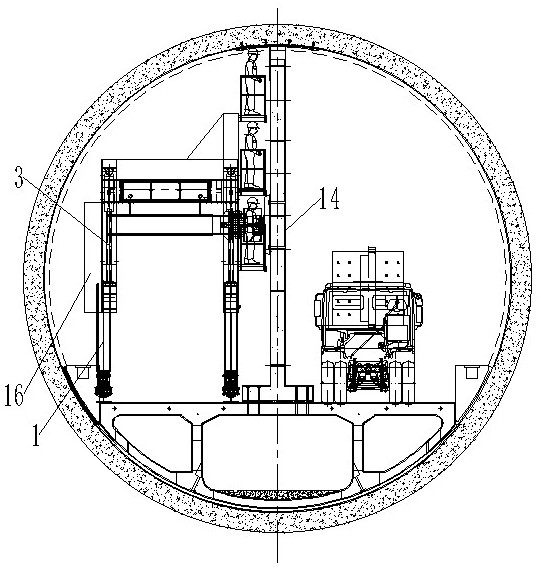

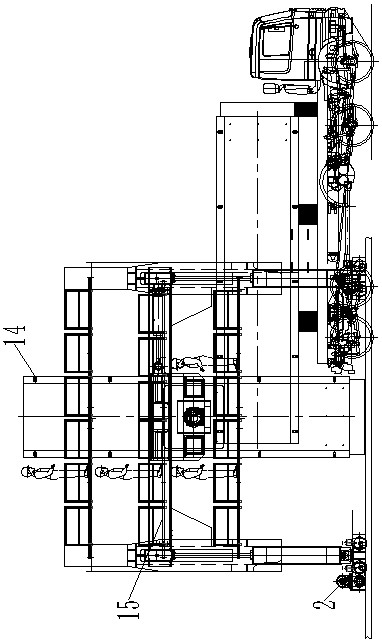

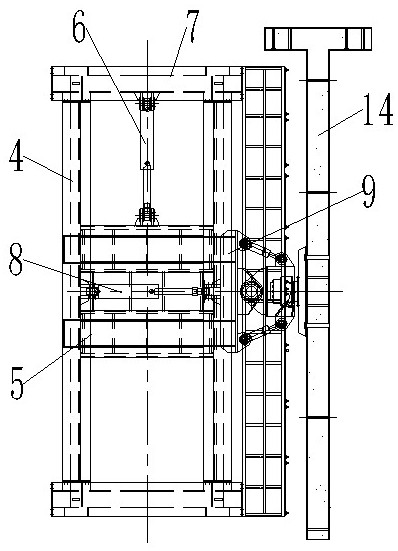

[0020]The technical solution of the present invention will be described in detail with reference to the accompanying drawings. Such asFigure 1-4As shown, a shield tunnel prefabricated medium block mounting device, including the main frame assembly, installation trolley assembly, and grabbing;

[0021]The main frame assembly is placed on the track by a travel wheel 2 provided at the bottom of its bottom, and is used to move the machine to the prefabricated interior wall construction mounting position. The door rack 1 is fixed to the installation truck assembly at the upper portion of the main frame.

[0022]The mounting truck assembly is fixed to the cylinder rod of the main frame lifting cylinder 3 for adjusting the adjustment of the installation cart assembly to the mounting cart assembly, and the longitudinal mobile trolley 5 is slidably equipped with a small car. On the rail mechanism 4, the longitudinal moving truck 5 is connected to the cylinder rod of the longitudinal directional ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com