Fan hub center constant-current hot-wire wind speed sensing system and method

A technology of hot wire wind speed and sensing system, which is applied in the direction of wind turbine, wind turbine monitoring, engine, etc. It can solve the problems such as wake flow generated by blades, influence on the real-time flow field distribution above the nacelle, and real inflow deviation of measurement results, etc., to achieve The effect of measuring flow field interference is small, the installation method is simple, and the overall cost is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

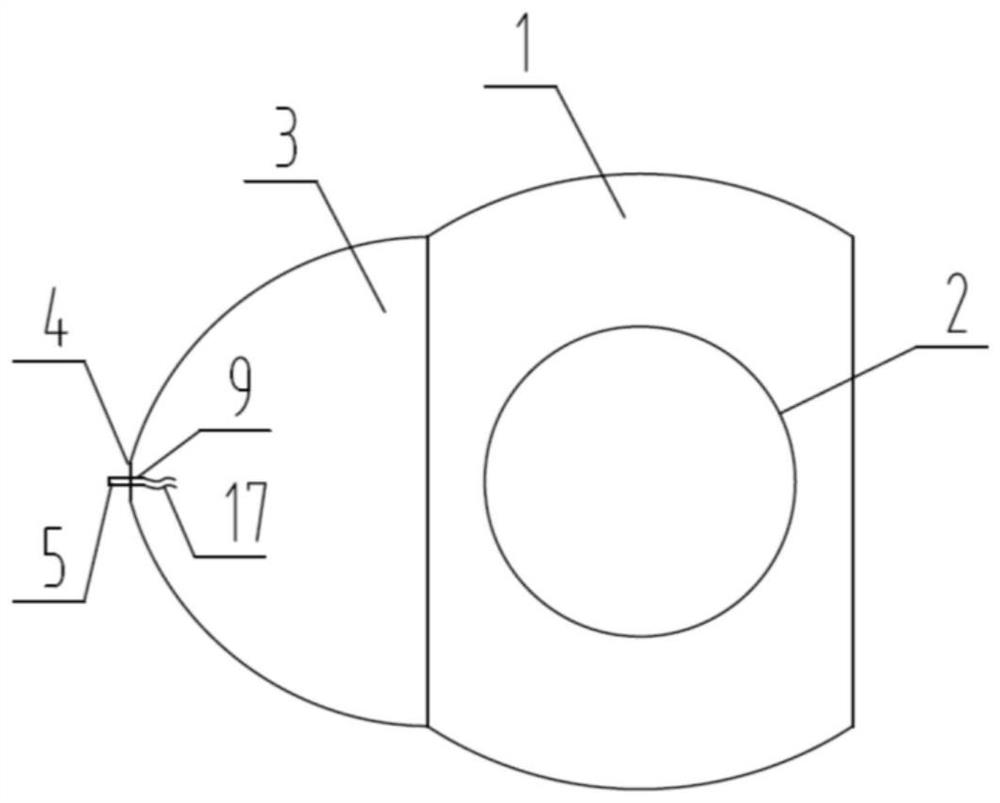

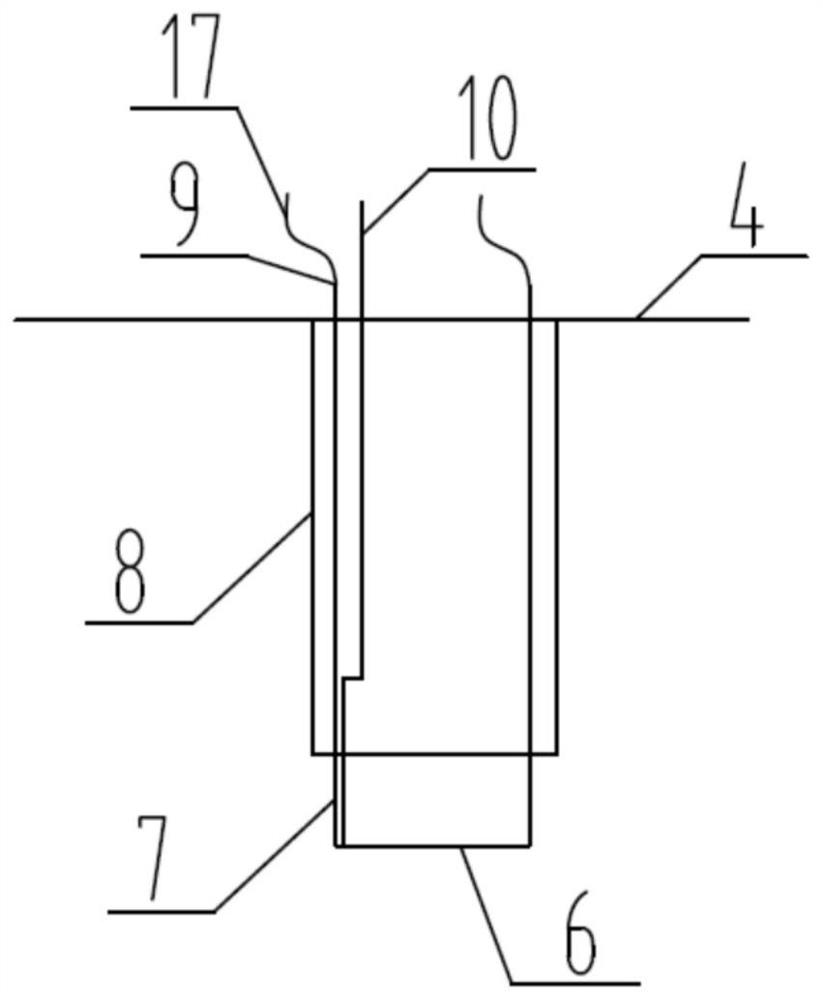

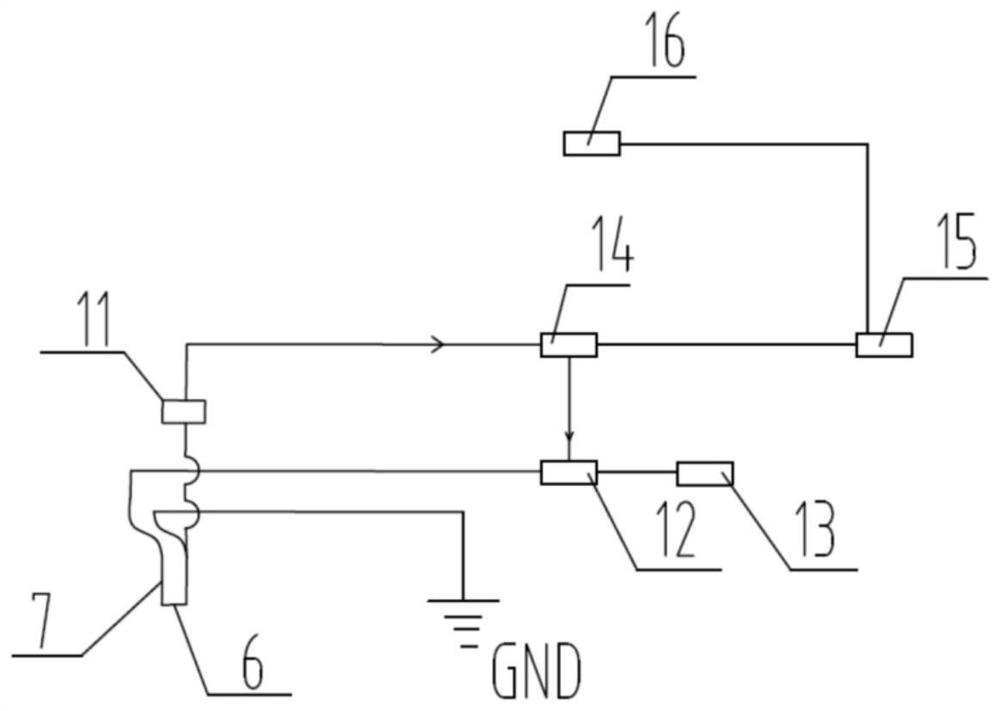

[0031] Compared with traditional wind measuring devices, hot wire wind speed sensing technology (also known as hot wire sensing technology) has significant advantages in measuring fluid velocity. The basic principle is to flow the heating current through the hot wire wire in the hot wire probe, and establish the parameters of the hot wire current, temperature and wind speed based on the energy balance of the hot wire wire (including self-heating, convective heat transfer and radiation heat transfer, etc.). exact correspondence. The hot wire can be divided into constant temperature and constant current in the working mode, that is to keep the heating current and temperature of the hot wire probe constant respectively. For the constant current hot wire anemometer, after calibration, there is a corresponding relationship between the heat balance temperature of the metal wire and the ambient air flow when the wind speed changes. It only needs to accurately monitor the temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com