Optical fiber device, manufacturing method and acoustic Mach-Zehnder interferometer in optical fiber

A technology for optical fiber devices and manufacturing methods, applied in the field of optical information processing, can solve the problems of cumbersome preparation process, large size, and fragile structure, and achieve the effects of eliminating cumbersome processes, light center mass, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

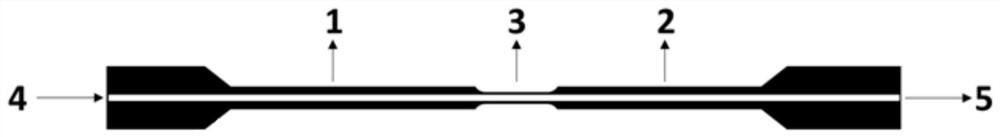

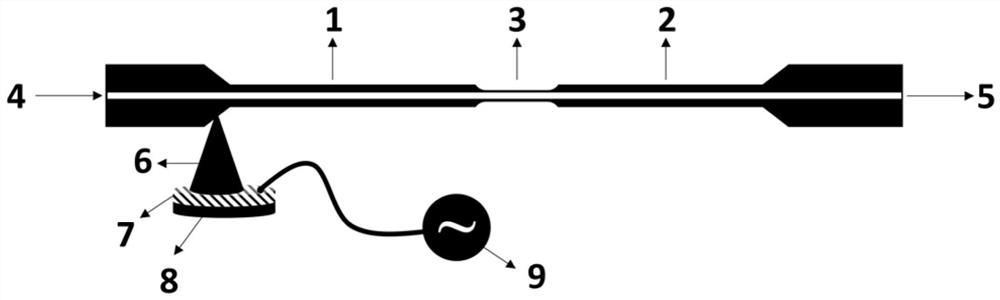

[0046] figure 1 A schematic structural diagram of an optical fiber device applied to an acoustically induced Mach-Zehnder interferometer in an optical fiber according to Embodiment 1 of the present invention is shown.

[0047] like figure 1 As shown, an optical fiber device applied to an acoustically induced Mach-Zehnder interferometer in an optical fiber, including: a single-mode optical fiber and a sandwich structure formed on a section of the single-mode optical fiber;

[0048] The sandwich structure includes the first acousto-optic active area 1, the second acousto-optic active area 2 and the interference arm area 3 coaxial with the single-mode fiber, and the interference arm area 3 is located in the first acousto-optic active area 1 and the second acousto-optic active area between 2;

[0049] The diameters of the first acousto-optic active zone 1 and the second acousto-optic active zone 2 are equal, and the diameter of the first acousto-optic active zone 1 is smaller th...

Embodiment 2

[0059] A method for manufacturing an optical fiber device applied to an acoustically induced Mach-Zehnder interferometer in an optical fiber, used to manufacture an optical fiber device applied to an acoustically induced Mach-Zehnder interferometer in an optical fiber according to the above fact 1, the method comprising:

[0060] Step S101: Provide a single-mode optical fiber, remove the coating layer of a predetermined area on the single-mode optical fiber, and use it as a preparation section of the sandwich structure;

[0061] In a specific application scenario, single-mode optical fiber is used to make optical fiber devices. The core diameter of single-mode optical fiber is very small, only 8-10 μm. The outer layer of the core is cladding, and the outer cladding is coating. Before the preparation, a part of the coating layer of the single-mode optical fiber is stripped as a preparation section of a sandwich structure, and only the inner fiber core and the outer cladding of t...

Embodiment 3

[0068] A method for manufacturing an optical fiber device applied to an acoustically induced Mach-Zehnder interferometer in an optical fiber, used to manufacture an optical fiber device applied to an acoustically induced Mach-Zehnder interferometer in an optical fiber according to the above fact 1, the method comprising:

[0069] Step S201: Provide a single-mode optical fiber, and remove the coating layer of a predetermined area on the single-mode optical fiber, as a preparation section of the sandwich structure;

[0070] Step S202: Etching the preparation section with an etching solution to reduce the diameter of the preparation section to a first preset diameter, where the first preset diameter is smaller than the cladding diameter of the single-mode optical fiber and larger than the core diameter of the single-mode optical fiber;

[0071] Step S203: Draw the middle region of the optical fiber preparation section into a double-cone structure by using the hydrogen-oxygen flame...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com