Thin film uniform deposition and high-precision patterning method based on liquid-phase MXene material and large-scale preparation method of photoelectric device

A technology of optoelectronic devices and material thin films, which is applied in the fields of electrical solid devices, semiconductor/solid device manufacturing, photovoltaic power generation, etc., can solve the problems of low processing precision and poor uniformity, and achieve the effect of high resolution and good photoelectric detection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In specific implementation process, the present invention is based on liquid phase MXene (such as: Ti 3 C 2 T x 、Ti 2 CT x etc.) uniform deposition of thin films of suspensions, high-precision patterning and large-scale preparation methods of photoelectric devices, through photolithography-dry etching process, the method of preparing patterned MXene material thin films and MXene-based photodetectors is as follows:

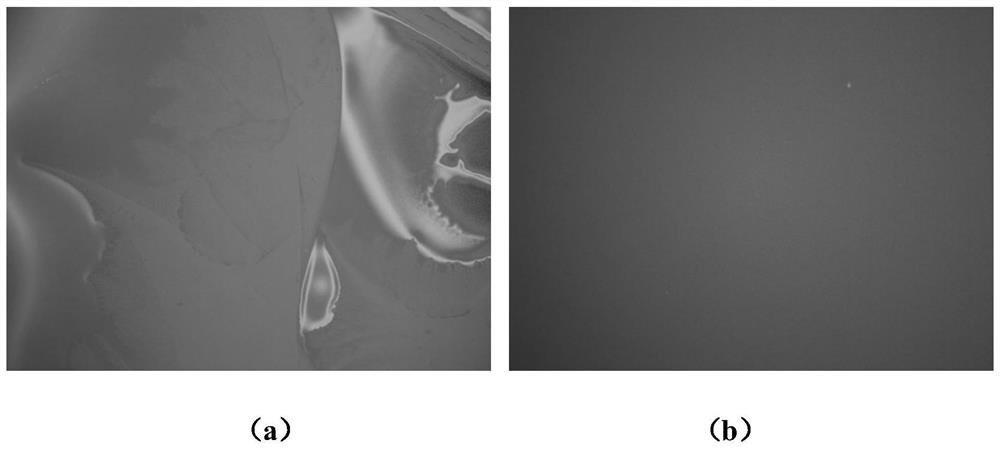

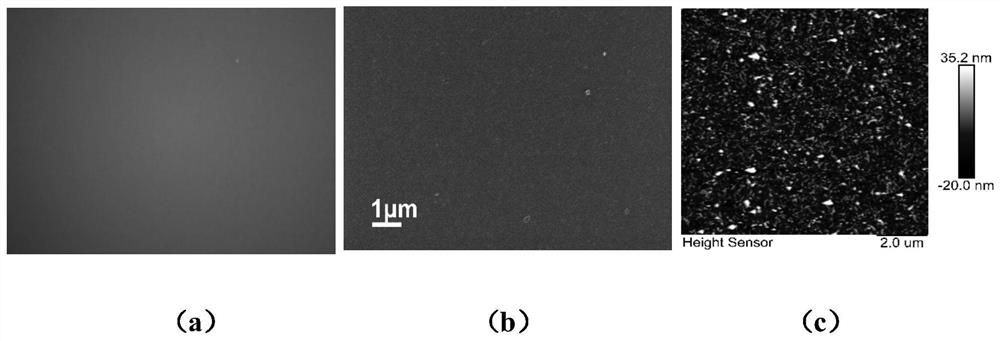

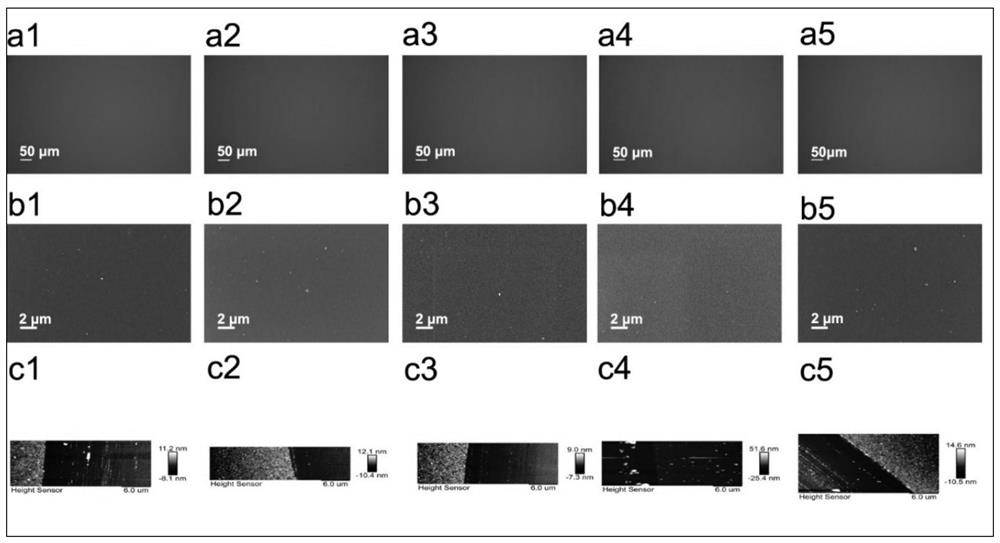

[0051] (1) It is necessary to verify the influence of suspension concentration, spin coating speed and spin coating time on the film formation effect during the preparation of MXene material thin film by spin coating MXene material suspension. First determine the concentration of the MXene material suspension and the spin-coating time, prepare different MXene material films by changing the speed of the homogenizer, and then control the other two parameters at a time to optimize the film-forming effect. The film formation effect was characterized by optic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com