Corona solder-resistant circuit board and preparation method thereof

A circuit board and solder resist technology, which is applied in printed circuit manufacturing, printed circuit, printed circuit components, etc., can solve the problems affecting the quality of circuit boards, oil rejection, PTFE material is easy to be collided, etc., and achieve good solder resist printing effect , enhance the bonding force, and improve the efficiency of spraying solder mask

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

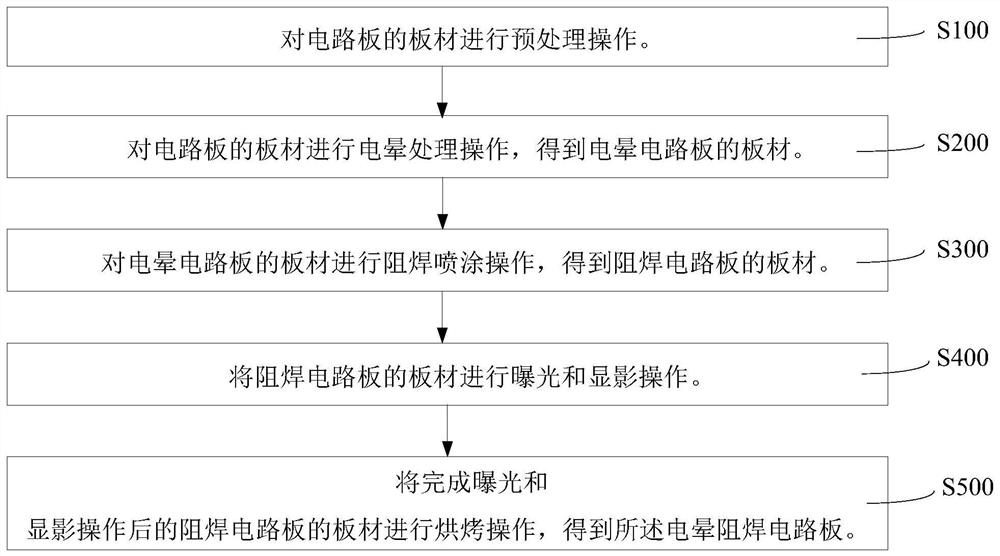

[0030] The present application provides a method for preparing a corona solder resist circuit board. The preparation method of the above-mentioned corona solder resist circuit board includes the following steps: performing a pretreatment operation on the board material of the circuit board; performing a corona treatment operation on the board material of the circuit board to obtain a board material of the corona circuit board; The plate of the circuit board is subjected to the solder resist spraying operation to obtain the plate of the solder resist circuit board; the plate of the solder resist circuit board is subjected to exposure and development operations; the plate of the solder resist circuit board after the exposure and development operations are completed is subjected to Baking operation to obtain the corona solder resist circuit board.

[0031] The preparation method of the above-mentioned corona solder resist circuit board is to corona-treat the plate of the circuit ...

Embodiment 1

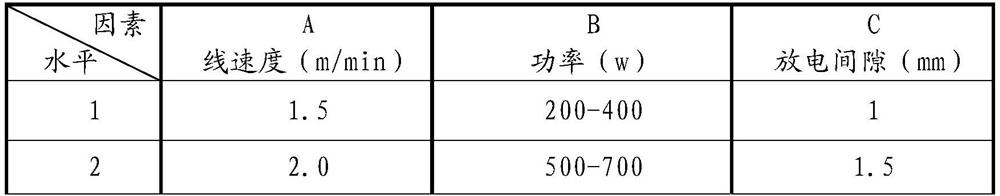

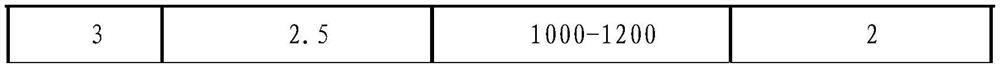

[0060] The PTFE sheet is selected as the board of the circuit board, and the PTFE sheet is subjected to super-roughening treatment. Then corona treatment is carried out to the treated PTFE sheet, wherein the voltage during the corona treatment is 8000V, the discharge power is 200W, the discharge gap is 1mm, and the processing line speed is 1.5m / min. After the corona treatment is completed on the PTFE sheet, use a low-pressure spraying method to atomize the ink through a spray gun and then spray it on the surface of the circuit board. After spraying evenly, let it stand for 25 minutes, and then spray the sprayed circuit board Pre-baking at 60° C. for 25 minutes, and then exposing and developing the solder resist circuit board. After the exposure and development operations are completed, the plate of the solder resist circuit board is baked in sections, sequentially baked at 80°C for 1 hour, baked at 100°C for 0.5 hour, and baked at 120°C for 0.5 hour. After the baking is compl...

Embodiment 2

[0062] The PTFE sheet is selected as the board of the circuit board, and the PTFE sheet is subjected to super-roughening treatment. Then corona treatment was performed on the treated PTFE sheet, wherein the voltage during the corona treatment was 12000V, the discharge power was 1200W, the discharge gap was 2mm, and the processing line speed was 3.0m / min. After the corona treatment is completed on the PTFE sheet, use the low-pressure spraying method to atomize the ink through the spray gun and then spray it on the surface of the board of the circuit board. Pre-baking at 70° C. for 30 minutes, and then exposing and developing the solder resist circuit board. After the exposure and development operations are completed, the plate of the solder resist circuit board is baked in sections, sequentially baked at 90°C for 1 hour, baked at 110°C for 0.5 hour, and baked at 130°C for 0.5 hour. After the baking is completed, a corona solder resist circuit board is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com