Preparation device and method for producing stearic acid in-situ modified calcium hydroxide by dry method digestion process

A calcium hydroxide, in-situ modification technology, applied in chemical instruments and methods, mixing methods, drying gas layout, etc., can solve the problem that the hydrophobic and lipophilic properties of the surface of calcium hydroxide have not been improved, and it is not suitable for industrial production and production technology. Complexity and other problems, to avoid deterioration, narrow particle size distribution, and large activation degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

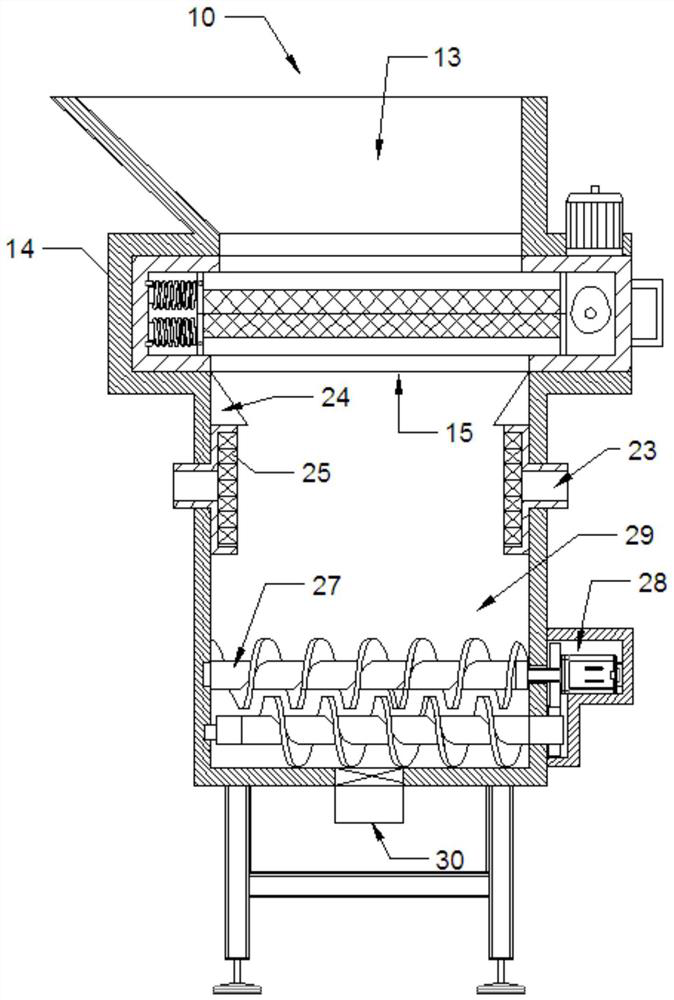

[0046] A dry digestion process produces stearic acid in-situ modified calcium hydroxide preparation method, comprising the following steps:

[0047] (1) Open the screen digester 10, calcium oxide and stearic acid aqueous solution are synchronously added to the screen digester 10 to carry out the digestion reaction;

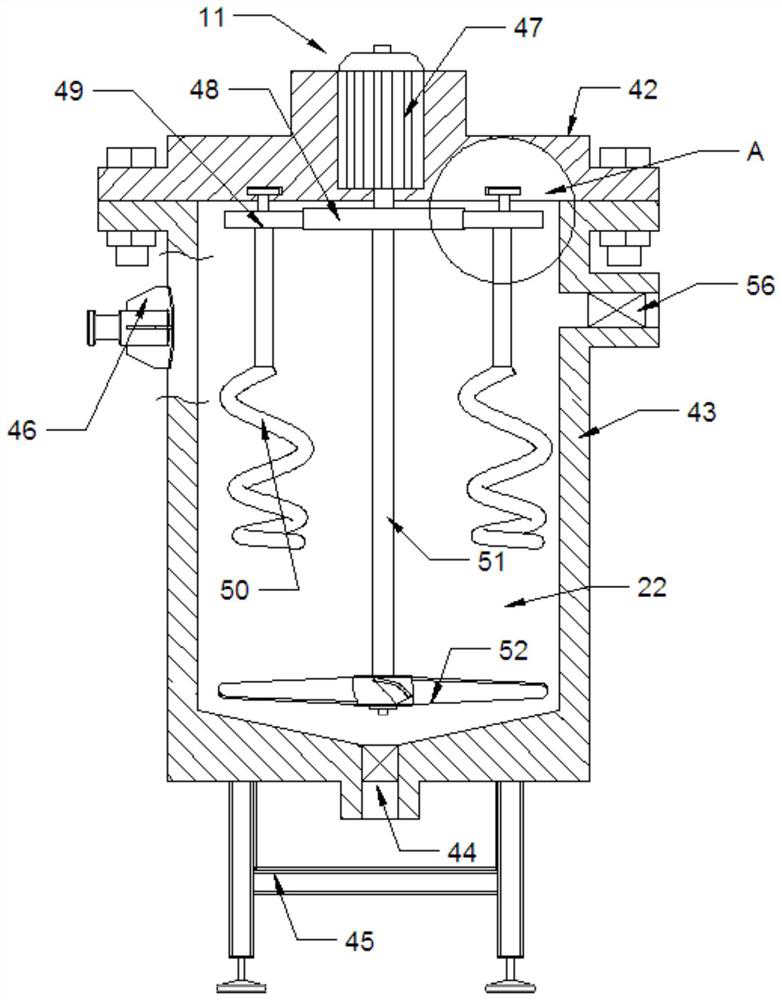

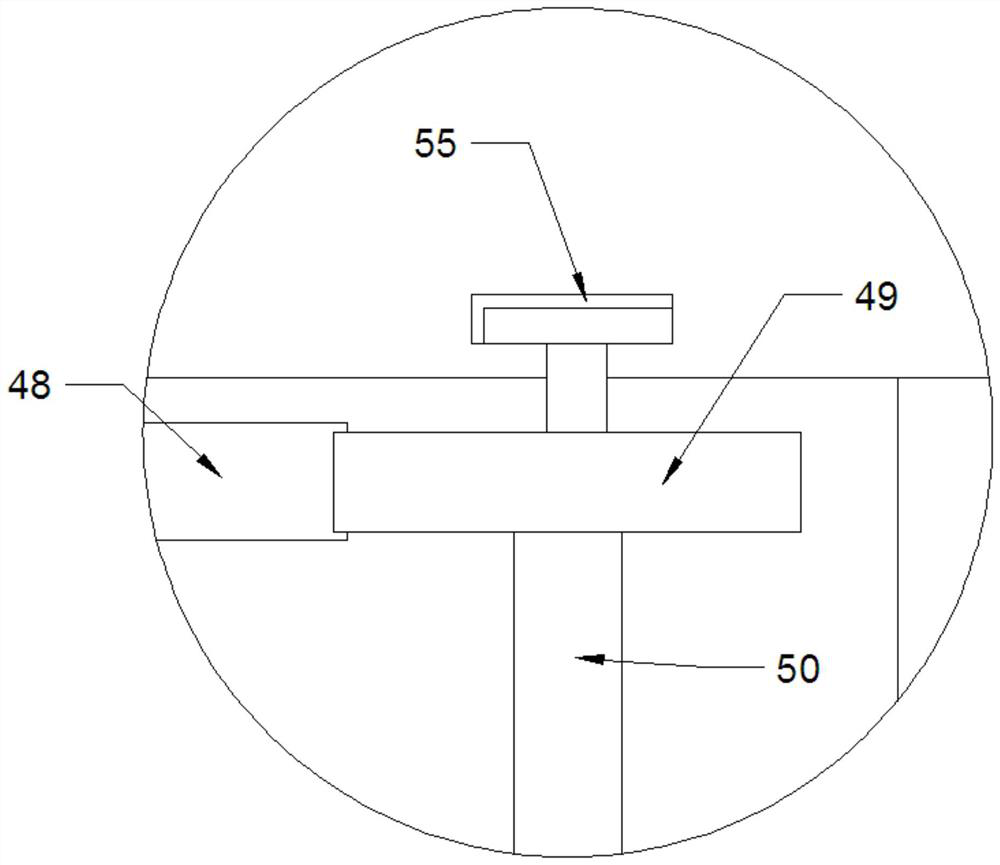

[0048] (2) Regulate the flow rate of the stearic acid feed port 46 and the flow rate of the water injection port 56, so that the mass ratio of hot water for digestion and calcium oxide is 0.6:1;

[0049] (3) adjust the flow rate of stearic acid water inlet 23 on the left and right sides so that the temperature of the digested hot water is 80°C;

[0050] (4) Regulate the vibration frequency of the screen cloth 20 so that the mass ratio of stearic acid to calcium oxide is 4:100;

[0051] (5) Open the right stearic acid water inlet 23, adjust the cooling water flow rate, and control the reaction temperature in the digester to be 140°C ± 2°C;

[0052] (6) Regulate t...

Embodiment 2

[0055] A dry digestion process produces stearic acid in-situ modified calcium hydroxide preparation method, comprising the following steps:

[0056] (1) Open the screen digester 10, calcium oxide and stearic acid aqueous solution are synchronously added to the screen digester 10 to carry out the digestion reaction;

[0057] (2) Regulate the flow rate of the stearic acid feed port 46 and the flow rate of the water injection port 56, so that the mass ratio of hot water for digestion and calcium oxide is 0.5:1;

[0058](3) adjust the flow rate of the stearic acid water inlet 23 on the left and right sides so that the temperature of the digested hot water is 70°C;

[0059] (4) adjust the vibration frequency of the screen cloth 20 so that the mass ratio of stearic acid to calcium oxide is 5:100;

[0060] (5) Open the stearic acid water inlet 23 on the right side, adjust the cooling water flow rate, and control the reaction temperature in the digester to be 130°C ± 2°C;

[0061] (...

Embodiment 3

[0064] A dry digestion process produces stearic acid in-situ modified calcium hydroxide preparation method, comprising the following steps:

[0065] (1) Open the screen digester 10, calcium oxide and stearic acid aqueous solution are synchronously added to the screen digester 10 to carry out the digestion reaction;

[0066] (2) Regulate the flow rate of the stearic acid feed port 46 and the flow rate of the water injection port 56, so that the mass ratio of hot water for digestion and calcium oxide is 0.4:1;

[0067] (3) adjust the flow rate of the stearic acid water inlet 23 on the left and right sides so that the temperature of the digested hot water is 75°C;

[0068] (4) Regulate the vibration frequency of the screen cloth 20 so that the mass ratio of stearic acid to calcium oxide is 3:100;

[0069] (5) Open the stearic acid water inlet 23 on the right side, adjust the cooling water flow rate, and control the reaction temperature in the digestion machine to be 120°C ± 2°C;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com