Absorbable hemostasis composite material based on polyanionic cellulose, and preparation method of absorbable hemostasis composite material

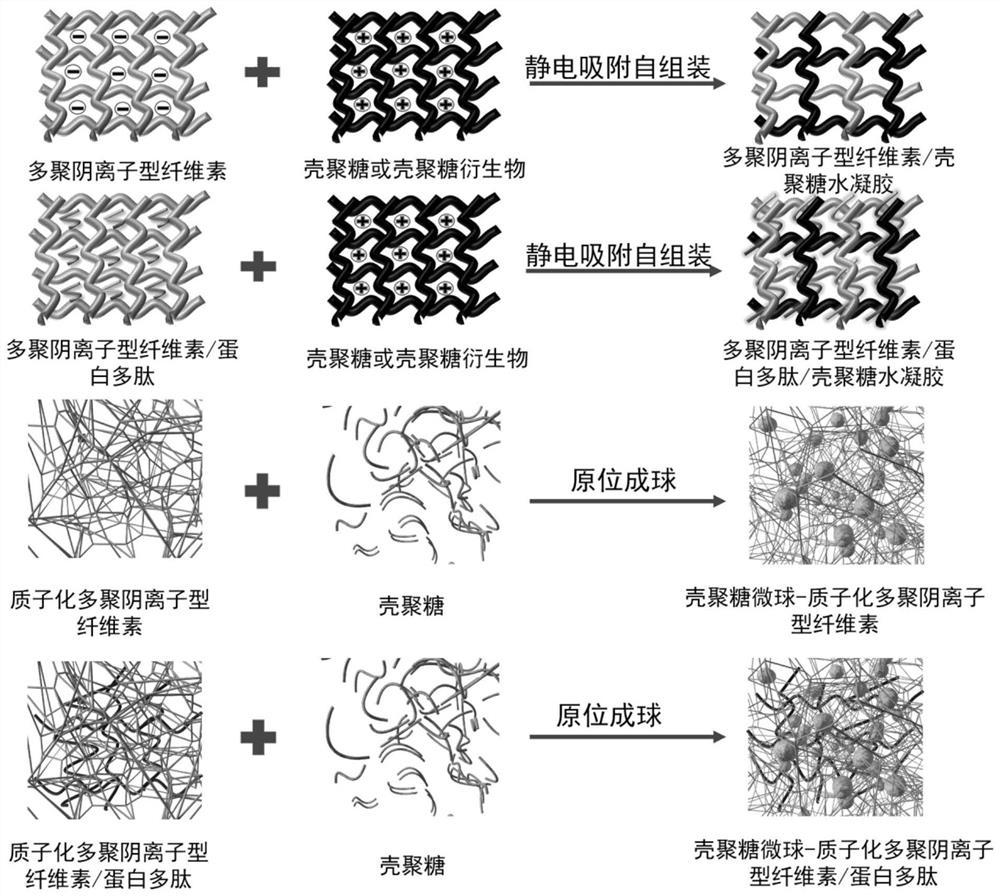

A technology of polyanionic and composite materials, which is applied in the field of absorbable hemostatic composite materials and its preparation, can solve the problems of weak antibacterial performance, low biocompatibility, and single hemostatic mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

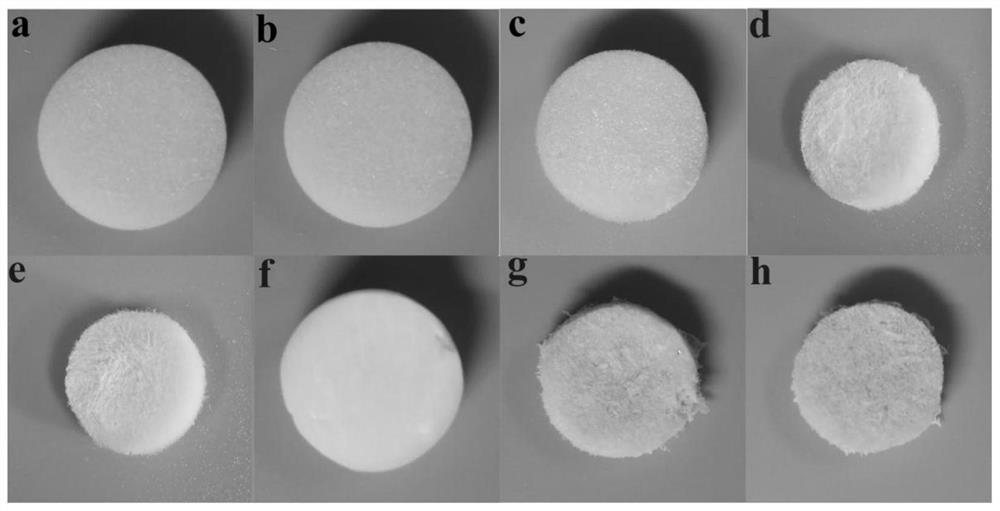

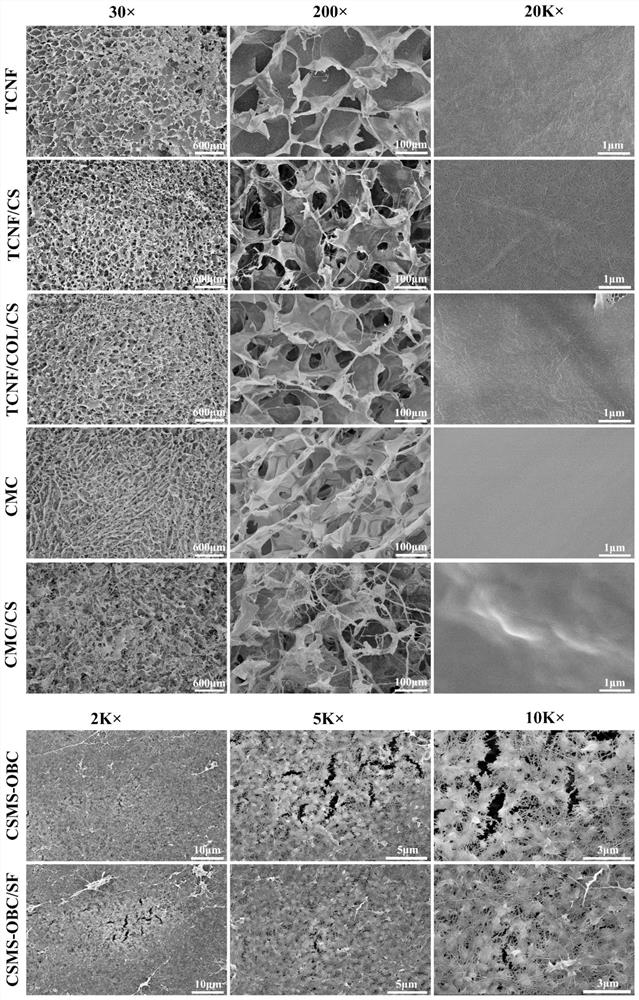

Examples

Embodiment 1

[0060] (1) The plant-derived oxidized cellulose nanofiber suspension (model NFC1904H) purchased from the market (Zhongshan Nanofiber New Material Co., Ltd.), the oxidation system is TEMPO / NaClO / NaBr co-oxidation system, English is TEMPO-oxidizedCellulose Nano-fiber , referred to as TCNF) was diluted with deionized water to a solid content of 1% (w / v), and fully stirred to obtain a uniform suspension with a pH value of 6.

[0061] (2) Divide the suspension obtained in step (1) into molds, and pre-freeze in a refrigerator at -80 degrees Celsius for 12 hours, and put it into a freeze dryer for 48 hours after pre-freezing to obtain a plant-derived oxidized cellulose nanofiber hemostatic material (TCNF ).

Embodiment 2

[0063] (1) Dilute the plant source oxidized cellulose nanofiber suspension (model NFC1904H, oxidation system is TEMPO / NaClO / NaBr co-oxidation system) purchased by the market (Zhongshan Nafibril New Material Co., Ltd.) to solid content 1% (w / v), and fully stirred to obtain a uniform suspension with a pH value of 6.

[0064] (2) 1 g of chitosan (Chitosan, CS) with a molecular weight of 50,000 was weighed and fully dissolved in 100 mL of 0.1 M glacial acetic acid aqueous solution to form a chitosan dilute acid solution with a final concentration of 1%.

[0065] (3) get the suspension liquid that makes in 10mL step (1) and put into small beaker, take the step of 10mL again ( 2) The prepared dilute chitosan acid solution was slowly dropped dropwise into a beaker, stirred while adding dropwise, and reacted for 30 minutes.

[0066] (4) Adjust the pH value of the gel suspension obtained in step (3) to 6 and repeatedly centrifuge and rinse, and finally collect the gel precipitate acco...

Embodiment 3

[0069] (1) Dilute the plant source oxidized cellulose nanofiber suspension (model NFC1904H, oxidation system is TEMPO / NaClO / NaBr co-oxidation system) purchased by the market (Zhongshan Nafibril New Material Co., Ltd.) to solid content 1% (w / v), and fully stirred to obtain a uniform suspension with a pH value of 6.

[0070] (2) Put 10 mL of the suspension obtained in step (1) into a small beaker, and add 0.09 g of collagen according to the mass ratio of plant-derived oxidized cellulose nanofibers / collagen (Collagen, COL)=1 / 0.9 Put the powder into a small beaker, stir and absorb for 30 minutes to obtain a suspension of plant-derived oxidized cellulose nanofibers adsorbed with collagen. Collagen can come from aquatic animals, such as fish, or terrestrial animals, such as cows and pigs.

[0071] (3) Take 1 g of chitosan with a molecular weight of 50,000 and fully dissolve it in 100 mL of 0.1 M glacial acetic acid aqueous solution to form a final concentration of 1% chitosan dilut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com