Polyamide composite membrane, preparation method thereof and membrane element

A composite membrane and polyamide technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as difficult to break through cost control bottlenecks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

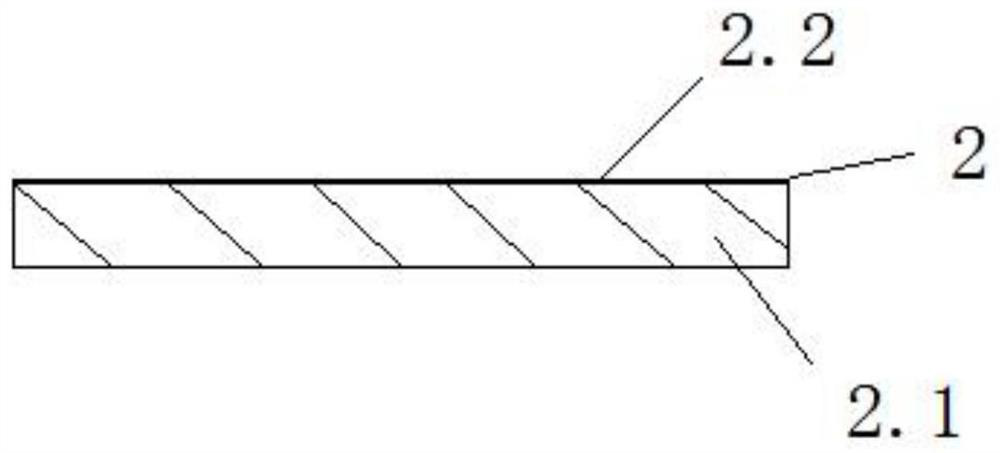

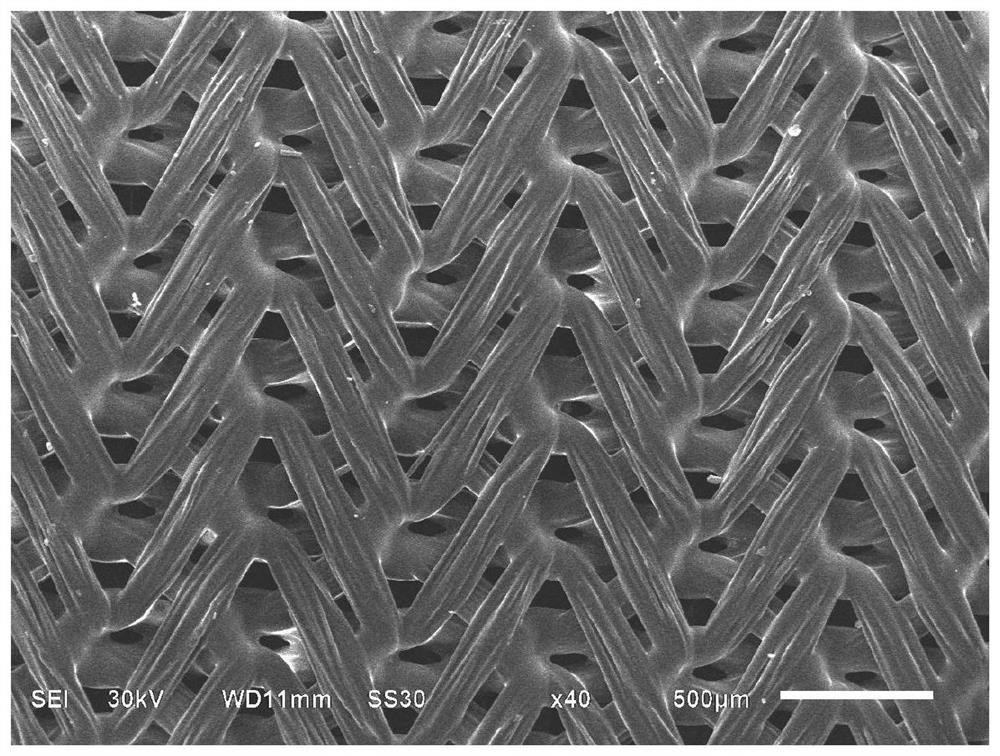

[0029] A kind of polyamide composite film 2, see for details figure 1 , including a substrate 2.1 and a polyamide layer 2.2 arranged in sequence; the substrate is composed of fresh water separators and polysulfone materials, and the polyamide layer is prepared on the surface of the substrate by interfacial polymerization of polyamines and polyacyl chlorides made. The SEM picture of the fresh water separation net is detailed in figure 2 , can be purchased from the prior art.

[0030] The preparation method of the polyamide composite membrane of the present embodiment may further comprise the steps:

[0031] Prepare the solution, specifically:

[0032] Dissolve 210g of polysulfone particles into 790g of N,N-dimethylformamide (DMF) and mix to form 1000g of polysulfone solution with a viscosity of about 3200cps. During the dissolution process, stir at a stirring speed of 400 rpm. The dissolution temperature The temperature is 75°C, and the dissolution time is 6 hours. After t...

Embodiment 2-8

[0042] The preparation process of Examples 2-8 is carried out with reference to the steps in Example 1, and the difference from Example 1 is in Table 2.

[0043] The different solution viscosities corresponding to different polysulfone concentrations are listed in Table 1:

[0044] Table 1 The solution viscosity corresponding to the concentration of polysulfone solution (25 ℃ test value)

[0045] Polysulfone Concentration (%) 15% 16% 17% 18% 19% 20% 21% 22% 23% Corresponding viscosity cps 425 708 789 1089 1556 2196 3193 4399 5738

Embodiment 9

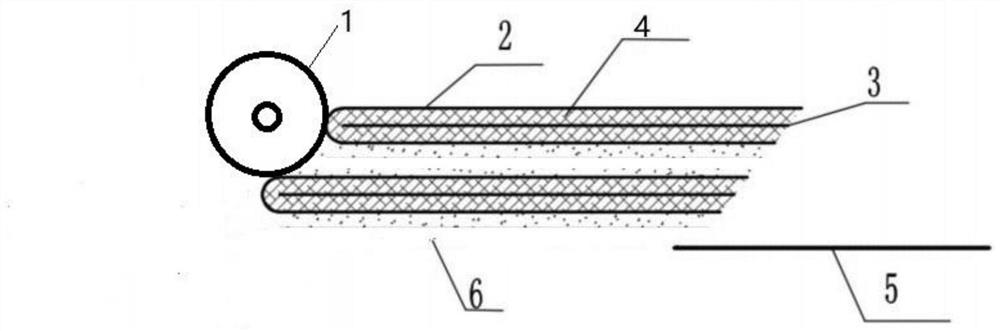

[0059] Adopt the polyamide composite membrane prepared by embodiment 6, make effective membrane area be 0.5m 2 , a separation membrane element with an outer diameter of 1.8 inches and a length of 12 inches. Structural diagram such as image 3 As shown, the specific method is:

[0060] Fold a piece of polyamide composite membrane 2 in half to form a polyamide composite membrane facing oppositely; fix the short sides of the polyamide composite membrane on the outer wall of the central tube 1 by pasting the two pages; The raw water flow path (circulation raw water 4) is formed between the fronts of the polyamide composite sheet, and the reverse side of the polyamide composite membrane in a single polyamide composite membrane or adjacent two polyamide composite membranes A water outlet channel (circulating water production 6 ) is formed between the membrane pieces, and the water outlet channel communicates with the pure water channel hole; finally, a sealing tape 5 is used for f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tension | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com