Monatomic catalyst, preparation method and application thereof

A catalyst and atom technology, applied in the field of organic compound catalytic synthesis, can solve problems such as low dispersion, and achieve the effects of high selectivity, easy separation and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

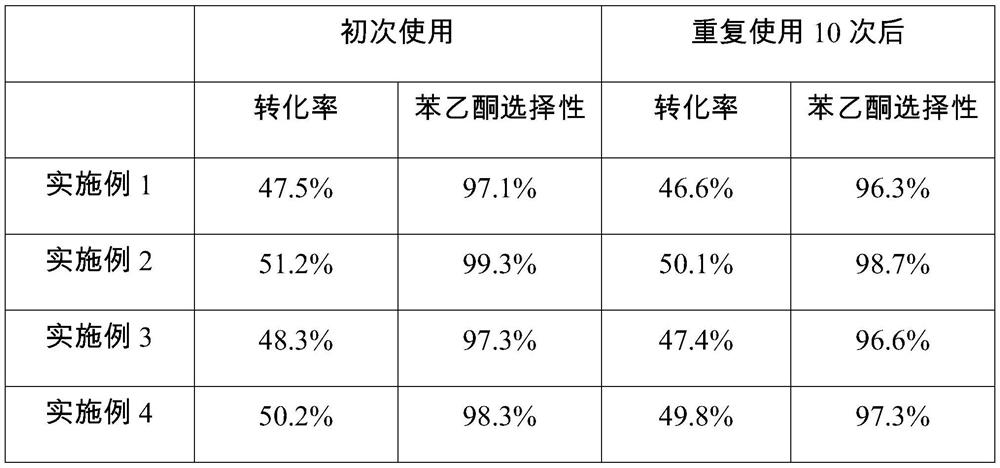

Examples

preparation example Construction

[0035] The preparation method of single atom catalyst of the present invention, comprises the steps:

[0036] (1) Add the MOFs material containing amino functional groups to an organic solvent, mix evenly, add an organic ligand and stir for reaction, the organic ligand contains carbon groups; the product after the reaction is washed and dried to obtain a mat-containing MOFs materials with alkali functional groups;

[0037] (2) Add the MOFs material containing the Schiff base functional group into the organic solvent, mix well, slowly add the transition metal precursor and continue to stir the reaction; wash and dry the reacted product, then pyrolyze at high temperature, pickle and dry , to obtain single-atom catalysts.

[0038] In the present invention, MOFs materials containing amino functional groups and organic ligands containing carbonyl and active nitrogen are used to form a mixed solution, and amino groups in MOFs materials are used to react with carbonyl groups in orga...

Embodiment 1

[0061] Take 1g of UiO66-NH2 and add it to 50mL of methanol, mix well, add 0.05g of pyridine-2-carboxaldehyde, stir and react at 20°C for 6h; wash the reacted product with deionized water, and dry at 50°C for 24h to obtain Schiff base-containing MOFs materials with functional groups; add MOFs materials containing Schiff base functional groups to 50mL methanol, mix well, slowly add 10mL 4g / L methanol solution of manganese acetate, stir and react at 20°C for 6h; wash the reacted product with deionized water After washing and drying at 50°C for 24 hours, it was pyrolyzed at 600°C for 1 hour, then washed with 0.5 mol / L sulfuric acid, and finally dried at 50°C for 24 hours to obtain a single-atom catalyst.

Embodiment 2

[0063] Take 1g of UiO66-NH2 and add it to 50mL of ethanol, mix well, add 0.1g of 2-dipyridyl ketone, stir and react at 30°C for 24h; wash the reacted product with deionized water and dry at 100°C for 12h to obtain the Schiff-containing MOFs materials with alkali functional groups; add MOFs materials containing Schiff base functional groups to 50mL ethanol, mix well, slowly add 10mL 100g / L ethanol solution of cobalt acetate, stir and react at 30°C for 24h; After washing with water and drying at 100°C for 12 hours, it was pyrolyzed at 800°C for 5 hours, then washed with 5 mol / L sulfuric acid, and finally dried at 100°C for 12 hours to obtain a single-atom catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com