Heat stabilizer composition for transparent PVC (polyvinyl chloride) and application of heat stabilizer composition

A heat stabilizer and auxiliary heat stabilizer technology, applied in the production of bulk chemicals, etc., can solve problems such as odor, poisonous organotin, poor static thermal stability and dynamic thermal stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

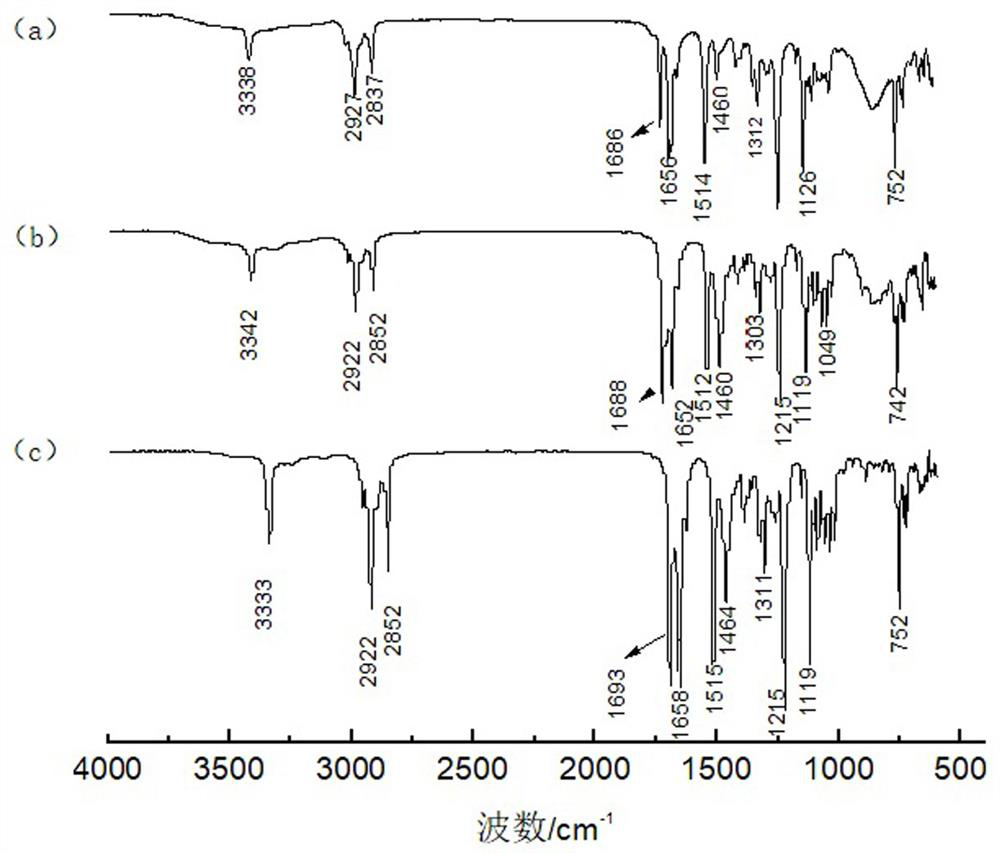

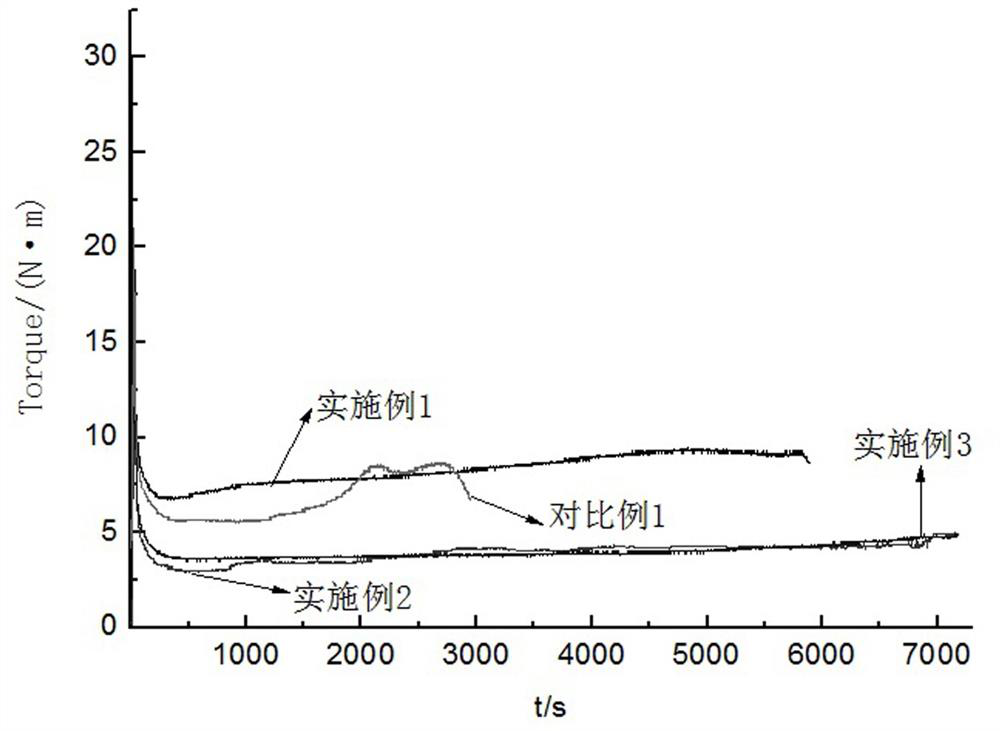

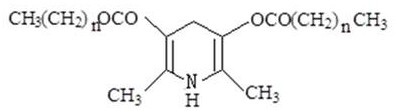

Method used

Image

Examples

Embodiment 1

[0036] Add 191.4 mL of CH to the flask 3 COCH 2 COOC 2 h 5 and a small amount of potassium hydroxide, in N 2 Stir and heat under the condition of gas protection. Add 223.2 mL of CH to the dropping funnel 3 (CH 2 ) 11 OH; when the temperature of the liquid in the flask reaches 175°C, CH 3 (CH 2 ) 11OH was dropped into the reaction flask, and the dropping speed was controlled to be 0.5 drops / s; after the addition of all the liquids, the reaction was continued at 175°C for 4 hours; Until there is a distillate, the product of the first step is obtained.

[0037] Prepare a new flask, add 324g of the product of the first step, and add a small amount of acetic acid until the liquid is weakly acidic; then add 77g of dried ammonium acetate and 7.29g of dried cetyltrimethylammonium bromide. 2 Stir, heat, and reflux under the condition of gas protection; dissolve 42.05g of urotropine in a small amount of distilled water and place it in the dropping funnel; Add the aqueous sol...

Embodiment 2

[0042] Add 191.4 mL of CH to the flask 3 COCH 2 COOC 2 h 5 and a small amount of potassium hydroxide, in N 2 Stir and heat under protected conditions. When the temperature of the liquid in the flask reached 190°C, 354.6g of CH 3 (CH 2 ) 23 OH was divided into 20 equal parts according to the principle of a small amount of multiple times, and added to the reaction flask in 20 times, adding one equal part every 10 minutes; 3 (CH 2 ) 23 After adding all the OH, continue the reaction at 190°C for 10 hours. After the reaction, lower the temperature to 80°C, and distill under reduced pressure until there is no more distillate, and the product of the first step is obtained.

[0043] Prepare a new flask, add 525.6g of the product from the first step, and add a small amount of acetic acid until the liquid appears weakly acidic. Then add 77g of dried ammonium acetate and 7.29g of dried cetyltrimethylammonium bromide, in N 2 Stirring, heating, and reflux under protected conditi...

Embodiment 3

[0047] Add 204.1 mL of CH to the flask 3 COCH 2 COOC 2 h 5 and a small amount of potassium hydroxide, in N 2 Stirring, heating, and reflux under protected conditions. When the temperature of the liquid in the flask reached 190°C, 354.6g of CH 3 (CH 2 ) 23 According to the principle of a small amount of multiple times, OH is divided into 20 parts, and added to the reaction flask in 20 times, one part is added every 10 minutes, and the CH 3 (CH 2 ) 23 After all the OH was added, the reaction was continued at 190°C for 10 hours. After the reaction was over, the temperature was lowered to 80°C, and distillation was performed under reduced pressure until there was no more distillate. , that is, the product of the first step is obtained.

[0048] Prepare a new flask, add 591.3g of the product from the first step, and add a small amount of acetic acid until the liquid becomes weakly acidic. Then add 79.06g of dried ammonium bicarbonate and 7.29g of dried cetyltrimethylammo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| transparency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com