Chemical-resistant transparent polycarbonate composite material with high glowing filament ignition temperature and preparation method thereof

A technology of ignition temperature and polycarbonate, applied in the field of polymer materials, can solve the problem that the flame retardant system cannot meet the high glow wire non-ignition of PC composite materials, so as to improve the flame retardant effect, simple raw materials, and expand the application field Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] A method for preparing a chemically resistant transparent polycarbonate composite material with a high glow wire ignition temperature of the present invention comprises the following steps:

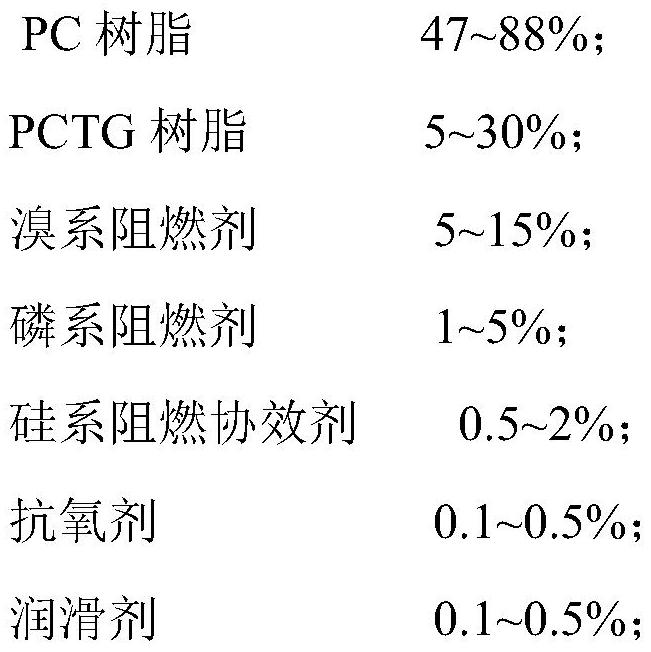

[0035] Step 1. Weigh each component successively according to the weight percentage of the above-mentioned raw materials, and take the PC resin, PCTG resin, brominated flame retardant, phosphorus flame retardant, silicon flame retardant synergist, antioxidant and The lubricant is mixed in a high-speed mixer for 5-10 minutes;

[0036] Step 2. Melting and extruding through a twin-screw extruder, cooling, and pelletizing to obtain a chemical-resistant transparent flame-retardant polycarbonate composite material with a high glow wire ignition temperature;

[0037] Wherein, the temperature setting of the twin-screw extruder in step 2 is: 200-230°C in the first zone, 230-250°C in the second zone, 230-250°C in the third zone, 230-250°C in the fourth zone, 230-250°C in the fifth zone, The...

Embodiment 1

[0046] According to the mass, put 47 parts of PC, 30 parts of PCTG, 15 parts of brominated flame retardant, 5 parts of phosphorus flame retardant, 2 parts of silicon flame retardant synergist, 0.5 part of antioxidant and 0.5 part of lubricant into the high speed In the mixer, mix at room temperature for 5 minutes and take it out; the above-mentioned uniformly mixed blend is melted and extruded through a twin-screw extruder, cooled, and granulated. The temperature of the twin-screw extruder is set at 200 ° C in the first zone. The second zone is 230°C, the third zone is 230°C, the fourth zone is 230°C, the fifth zone is 230°C, the sixth zone is 230°C, the seventh zone is 230°C, the eighth zone is 230°C, the head temperature is 230°C, and the screw speed of the extruder is controlled at 280r / min; and the obtained pellets were dried in a drying oven at a temperature of 100° C. for 3 hours to obtain a transparent PC material.

Embodiment 2

[0048]According to the mass, put 67.5 parts of PC, 17.5 parts of PCTG, 11.3 parts of brominated flame retardant, 3 parts of phosphorus flame retardant, 0.5 part of silicon flame retardant synergist, 0.1 part of antioxidant and 0.1 part of lubricant into the high speed In the mixer, mix at room temperature for 8 minutes and take it out; the above-mentioned uniformly mixed blend is melted and extruded through a twin-screw extruder, cooled, and granulated. The temperature of the twin-screw extruder is set at 215°C in the first zone. The second zone is 240°C, the third zone is 240°C, the fourth zone is 240°C, the fifth zone is 240°C, the sixth zone is 240°C, the seventh zone is 240°C, the eighth zone is 240°C, the head temperature is 240°C, and the extruder screw speed is controlled at 340r / min; and the obtained pellets were dried in a drying oven at a temperature of 105° C. for 4 hours to obtain a transparent PC material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com