Pure organic material with near-infrared phosphorescence emission as well as preparation method and application of pure organic material

A phosphorescent emission and organic material technology, applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of short wavelength and low mass production, and achieve the effects of stable luminescence properties, wide sources, and long phosphorescence life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

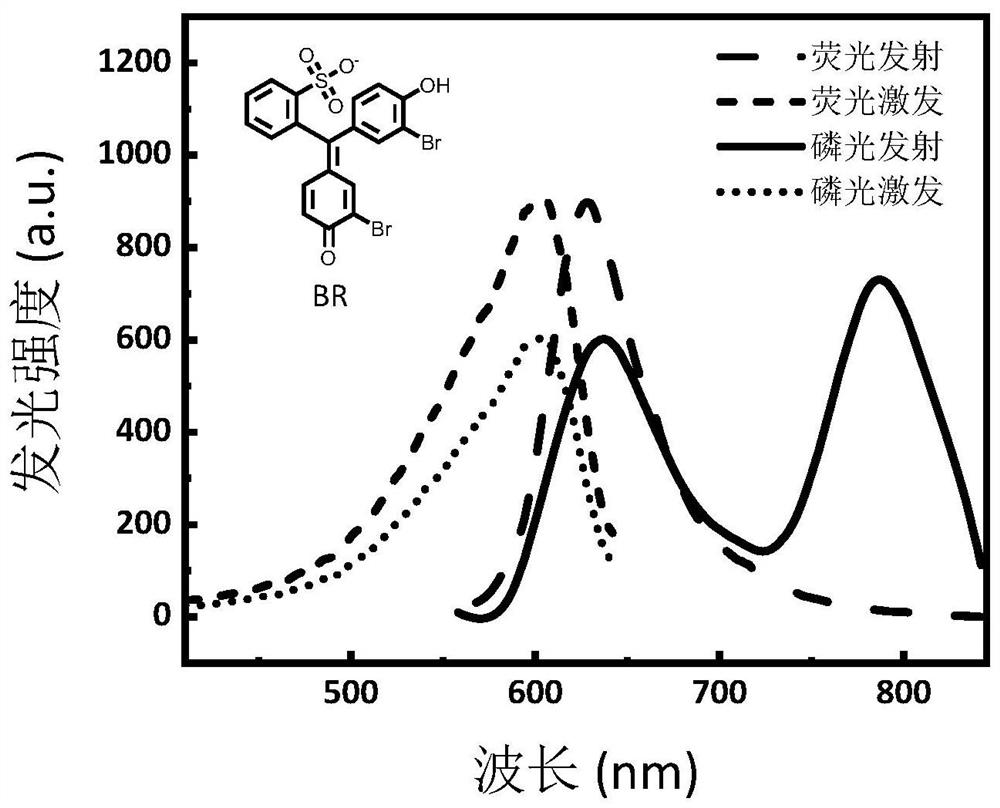

[0030] The pure organic material with near-infrared phosphorescent emission provided in this example comprises a guest material compound 1 (the structural formula is shown in formula I-1) and a host material polyvinyl alcohol (the structural formula is shown in formula II-1). Both were purchased directly from reagent companies. The specific steps for preparing pure organic materials with near-infrared phosphorescent emission by solvent method are:

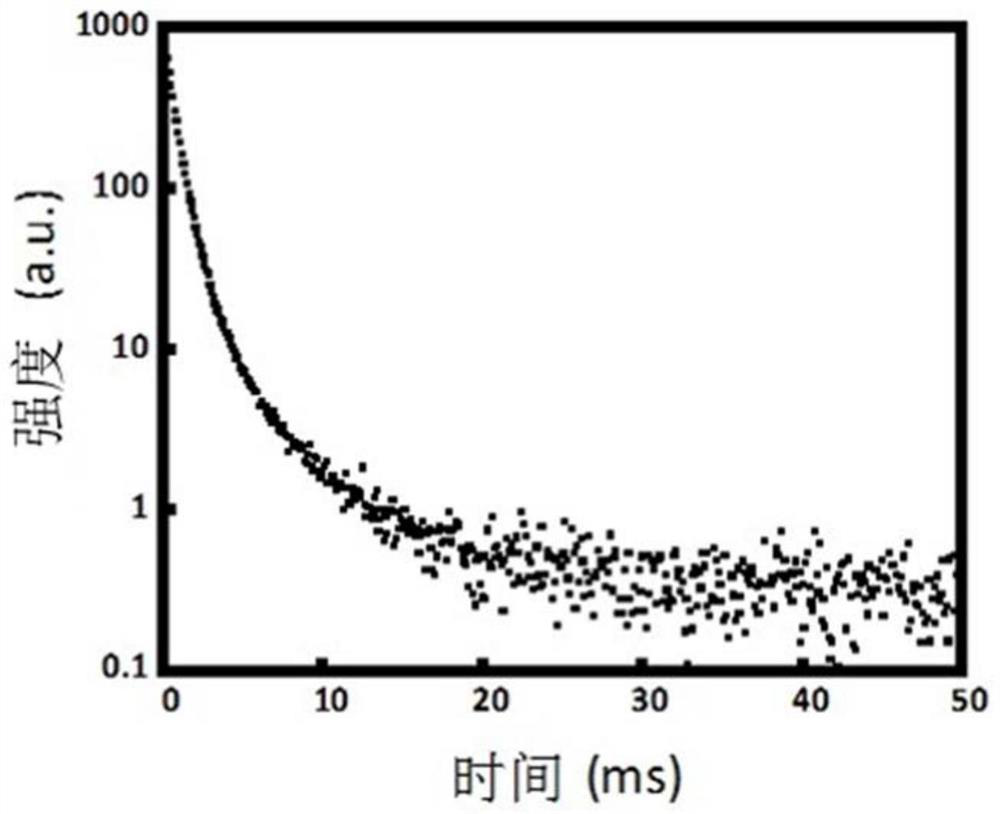

[0031] Compound 1 and polyvinyl alcohol were completely dissolved to make an aqueous solution, and then the two aqueous solutions were fully miscible to obtain a mixed solution (the mass ratio of compound 1 and polyvinyl alcohol was 1:100). The water in the system was removed from the mixed solution through a rotary evaporator to obtain a doped film. After vacuum drying the doped film for 12 h, a pure organic amorphous material with near-infrared phosphorescent emission was obtained. Its absolute phosphorescent quantum yield (int...

Embodiment 2

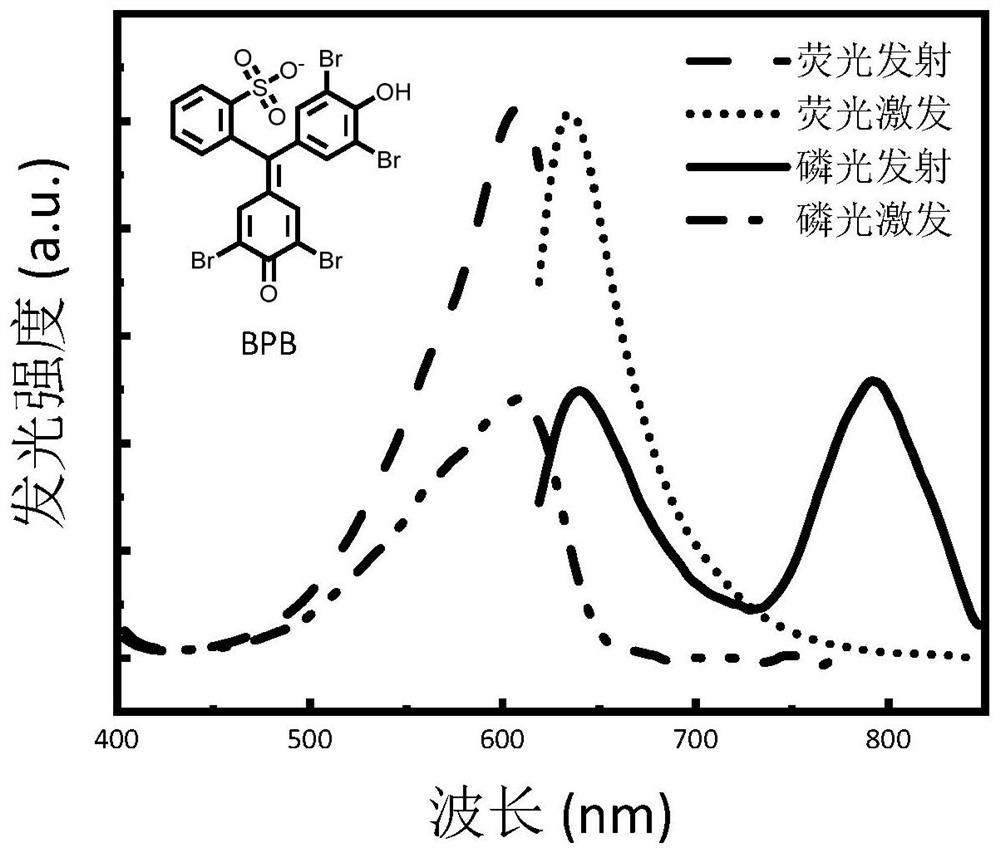

[0033] The pure organic material with near-infrared phosphorescence emission provided in this embodiment includes compound 2 (the structural formula is shown in formula I-2) and polyvinyl alcohol (the structural formula is shown in formula II-1). Both were purchased directly from reagent companies. The specific steps for preparing pure organic materials with near-infrared phosphorescent emission by solvent method are:

[0034] Compound 2 and polyvinyl alcohol were completely dissolved to make an aqueous solution, and then the two aqueous solutions were fully miscible to obtain a mixed solution (the mass ratio of compound 2 and polyvinyl alcohol was 1:100). The water in the system was removed from the mixed solution through a rotary evaporator to obtain a doped film. After vacuum drying the doped film for 12 h, a pure organic amorphous material with near-infrared phosphorescent emission was obtained. Its absolute phosphorescent quantum yield (integrating sphere method) is 2.6...

Embodiment 3

[0036] The pure organic material with near-infrared phosphorescent emission provided in this embodiment includes compound 3 (the structural formula is shown in formula I-3) and polyvinyl alcohol (the structural formula is shown in formula II-1). The specific steps for preparing pure organic materials with near-infrared phosphorescent emission by solvent method are:

[0037] Compound 3 and polyvinyl alcohol were completely dissolved to make an aqueous solution, and then the two aqueous solutions were fully miscible to obtain a mixed solution (the mass ratio of compound 3 and polyvinyl alcohol was 1:100). The water in the system was removed from the mixed solution through a rotary evaporator to obtain a doped film. After vacuum drying the doped film for 12 h, a pure organic amorphous material with near-infrared phosphorescent emission was obtained. Its absolute phosphorescent quantum yield (integrating sphere method) is 3.0%, and the phosphorescent emission peak is around 819nm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com