System for achieving mixed combustion with refuse derived fuel in pulverized coal boiler and operation method thereof

A technology for waste-derived fuel and pulverized coal boilers, which is applied in combustion methods, combustion using lump fuel and powder fuel, incinerators, etc., can solve the difficulty of site selection for waste incineration power plants, increase the risk of disease, and the NIMBY effect. highlight etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

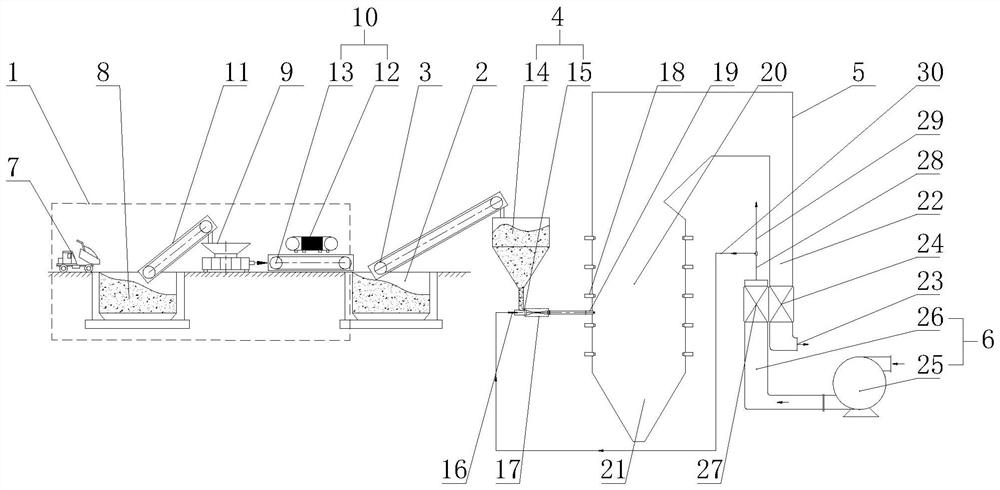

[0028] Embodiment 1 of the present invention: a pulverized coal boiler mixed-fired garbage-derived fuel system, including garbage-derived fuel pretreatment system 1, garbage-derived fuel product storage pit 2, A belt conveyor 3, garbage-derived fuel transfer device 4, Pulverized coal boiler 5 and air heating system 6, garbage-derived fuel pretreatment system 1 is connected with garbage-derived fuel finished product storage pit 2, garbage-derived fuel finished product storage pit 2 is connected with garbage-derived fuel transfer device 4 through A belt conveyor 3, garbage-derived fuel The derived fuel transfer device 4 is connected to the pulverized coal boiler 5, and the air heating system 6 is connected to the garbage derived fuel transfer device 4; it is upgraded on the existing waste incineration unit, with simple and reasonable structure, high equipment integration, simple operation and reliable operation , It solves the problem of difficult site selection for waste inciner...

Embodiment 2

[0029]Embodiment 2 of the present invention: a pulverized coal boiler mixed-fired garbage-derived fuel system, including garbage-derived fuel pretreatment system 1, garbage-derived fuel product storage pit 2, A belt conveyor 3, garbage-derived fuel transfer device 4, Pulverized coal boiler 5 and air heating system 6, garbage-derived fuel pretreatment system 1 is connected with garbage-derived fuel finished product storage pit 2, garbage-derived fuel finished product storage pit 2 is connected with garbage-derived fuel transfer device 4 through A belt conveyor 3, garbage-derived fuel The derived fuel transfer device 4 is connected to the pulverized coal boiler 5, and the air heating system 6 is connected to the garbage derived fuel transfer device 4; it is upgraded on the existing waste incineration unit, with simple and reasonable structure, high equipment integration, simple operation and reliable operation , which solves the problem of difficult site selection for waste incin...

Embodiment 3

[0030] Embodiment 3 of the present invention: a pulverized-coal boiler mixed-burning garbage-derived fuel system, including garbage-derived fuel pretreatment system 1, garbage-derived fuel product storage pit 2, A belt conveyor 3, garbage-derived fuel transfer device 4, Pulverized coal boiler 5 and air heating system 6, garbage-derived fuel pretreatment system 1 is connected with garbage-derived fuel finished product storage pit 2, garbage-derived fuel finished product storage pit 2 is connected with garbage-derived fuel transfer device 4 through A belt conveyor 3, garbage-derived fuel The derived fuel transfer device 4 is connected to the pulverized coal boiler 5, and the air heating system 6 is connected to the garbage derived fuel transfer device 4; it is upgraded on the existing waste incineration unit, with simple and reasonable structure, high equipment integration, simple operation and reliable operation , which solves the problem of difficult site selection for waste in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com