Etchant solution and method for displaying grain size of 0Cr17Ni4Cu4Nb precipitation hardening stainless steel

A technology of 0cr17ni4cu4nb and corrosion solution, which is applied in the field of metallographic detection and can solve the problem of unclear display of grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

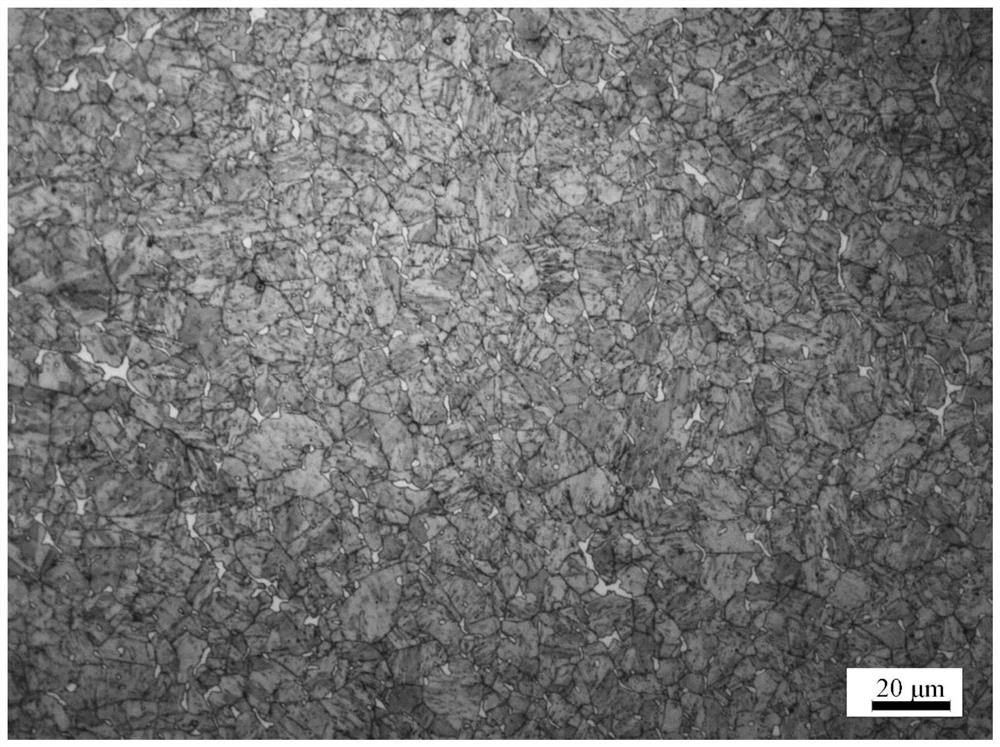

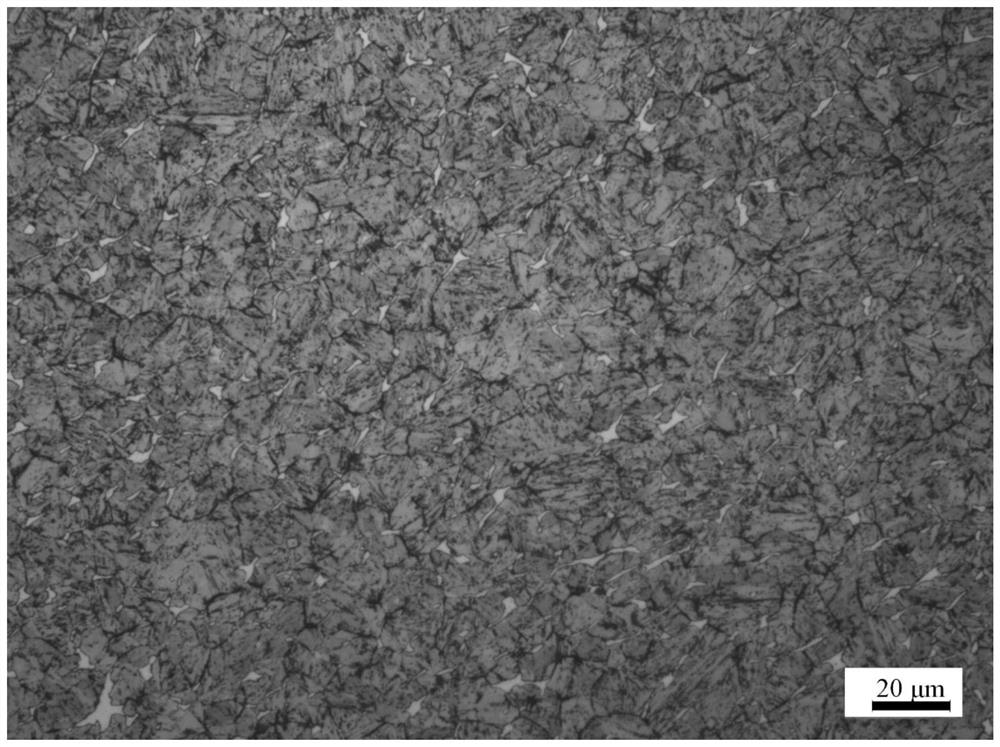

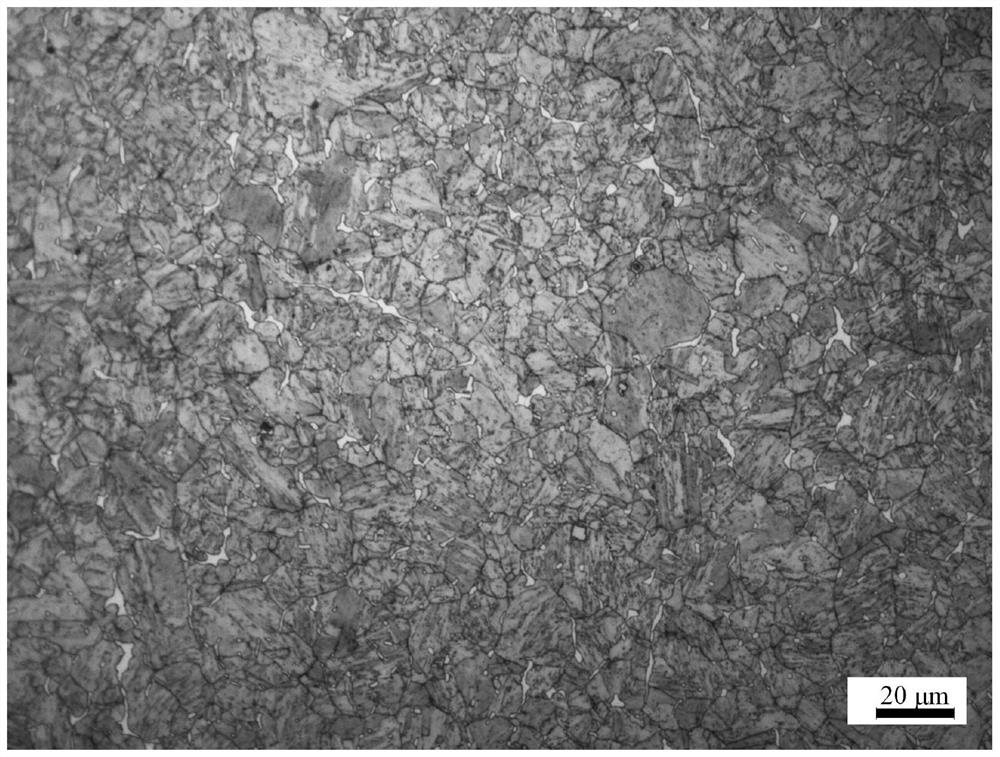

Image

Examples

Embodiment 1

[0027] Example 1 This example provides a corrosion solution for displaying the grain size of 0Cr17Ni4Cu4Nb precipitation hardening stainless steel, which includes two parts of corrosion solution A and corrosion solution B, wherein:

[0028] Corrosion solution A includes 10-15ml of 37% hydrochloric acid, 10-15g of ferric chloride and 85-90ml of deionized water;

[0029] Corrosion solution B includes 3-4ml of 40% HF solution, 10-15ml of alcohol (analytical grade), 6-7ml of 68% nitric acid solution, and 75-80ml of deionized water.

[0030] In this embodiment, the corrosion solution A is prepared with hydrochloric acid, which can prevent the hydrolysis of ferric ions in the ferric chloride solution during the process of corroding 0Cr17Ni4Cu4Nb precipitation hardened stainless steel. Since the potential of the ferric ions in the corrosion solution A is higher than that of the ferrous ions, the ferric ions can oxidize iron into ferrous ions and dissolve.

[0031] And due to the hig...

Embodiment 2

[0032] Example 2 This example provides a corrosion method for displaying the grain size of 0Cr17Ni4Cu4Nb precipitation hardening stainless steel, which includes the following steps:

[0033] Step 1. After inlaying and fixing the 0Cr17Ni4Cu4Nb precipitation hardened stainless steel sample through an automatic inlay machine, the inlay surface of the sample is polished on 180#, 400#, 1000#, 2000# water abrasive paper in turn——180#, 400 #, 1000#, and 2000# correspond to two coarse grinding processes and two fine grinding processes respectively, and then polish on a polishing machine until there are no scratches. Rinse with clean water first, then wash and dry with alcohol to make the sample to be corroded.

[0034] Step 2. Put 10-15ml of 37% hydrochloric acid, 10-15g of ferric chloride and 85-90ml of deionized water in proportion. Pour ferric chloride into deionized water fully, and stir fully with a glass until Dissolve everything to obtain solution a, then use a glass rod to dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com