Method for preparing polybenzazole fiber

A technology of phenylidene benzene and bisoxazole, which is applied in the field of polymer material preparation, can solve problems such as affecting the strength of the final product, incomplete closure of fiber holes, and increasing equipment load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

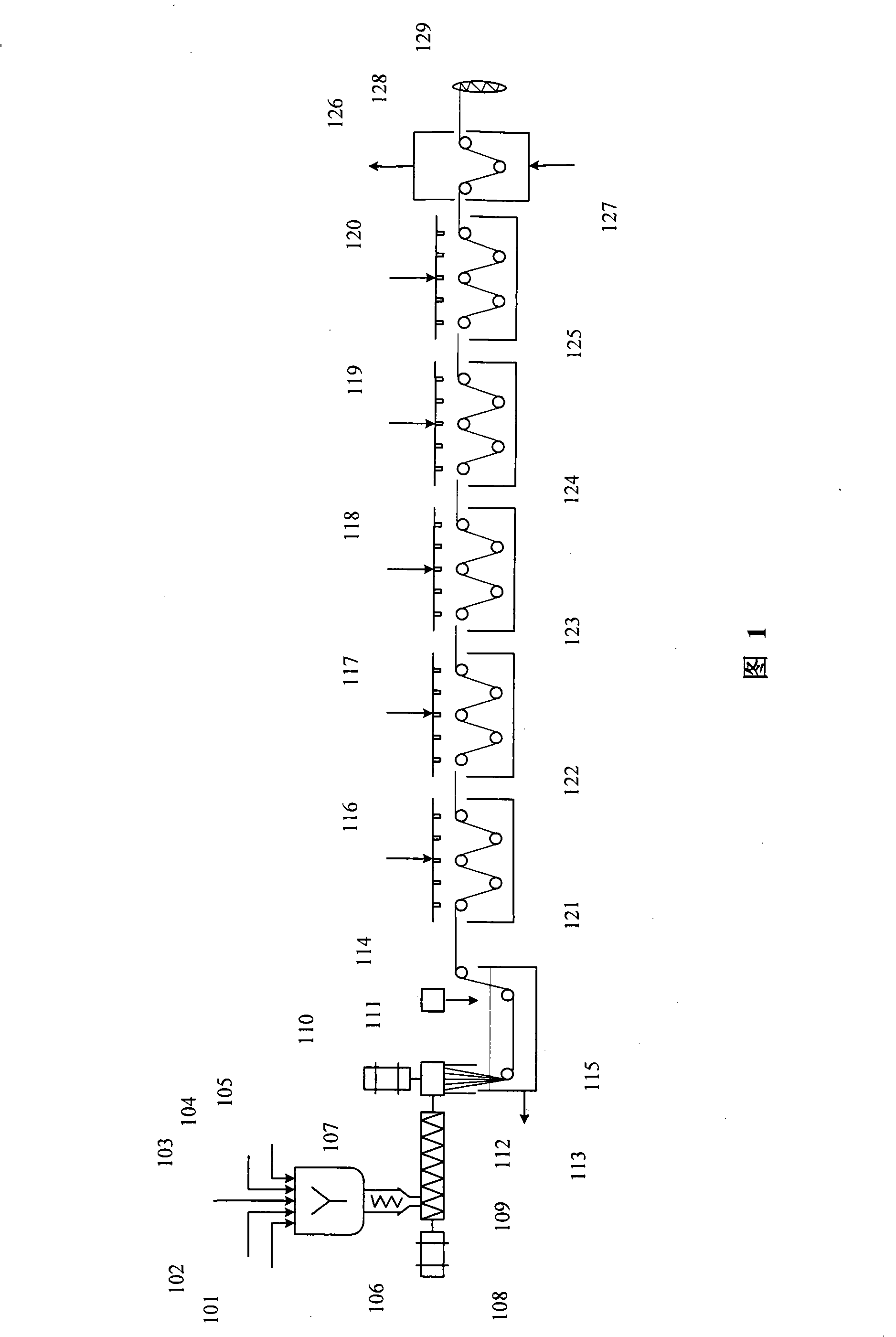

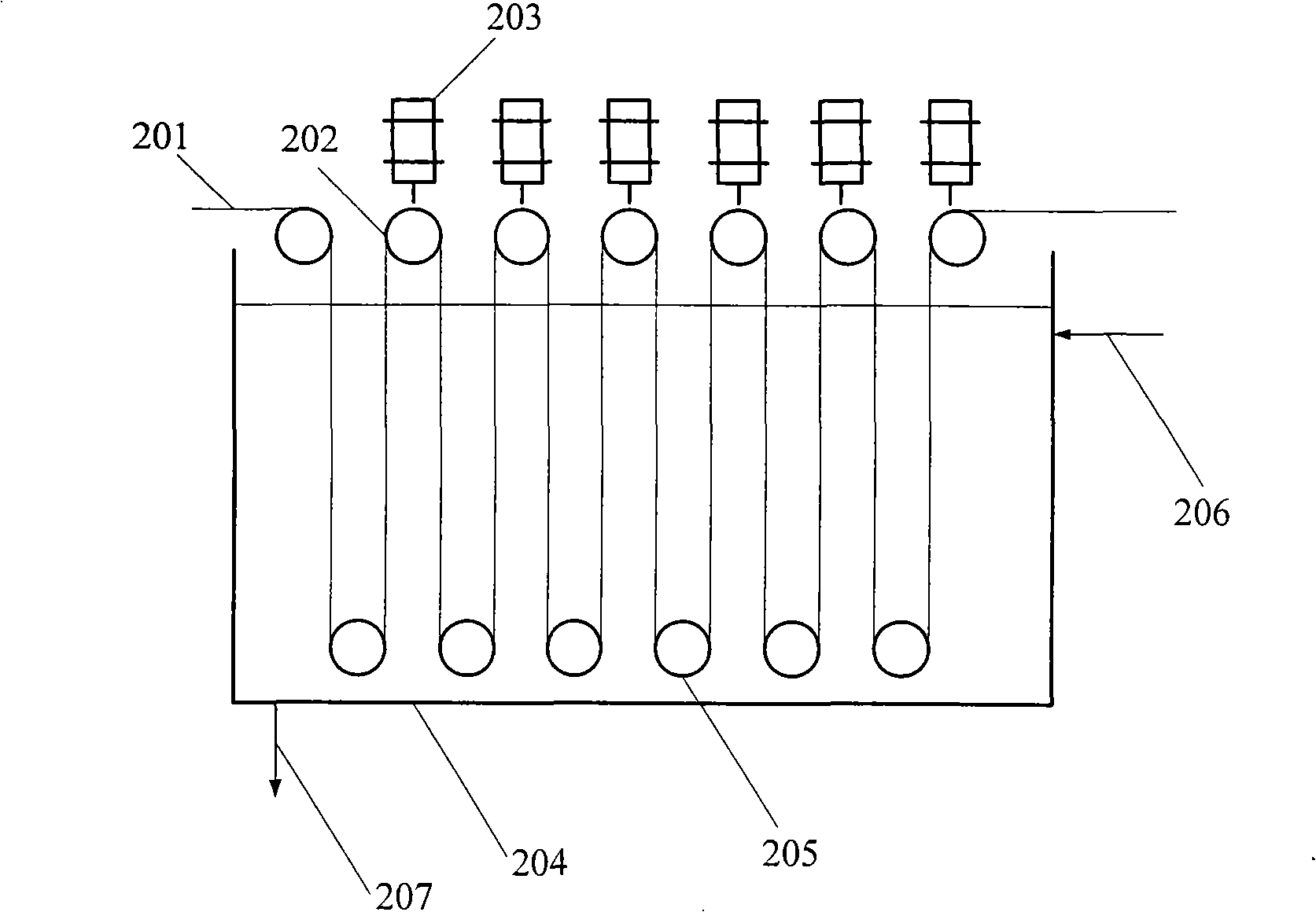

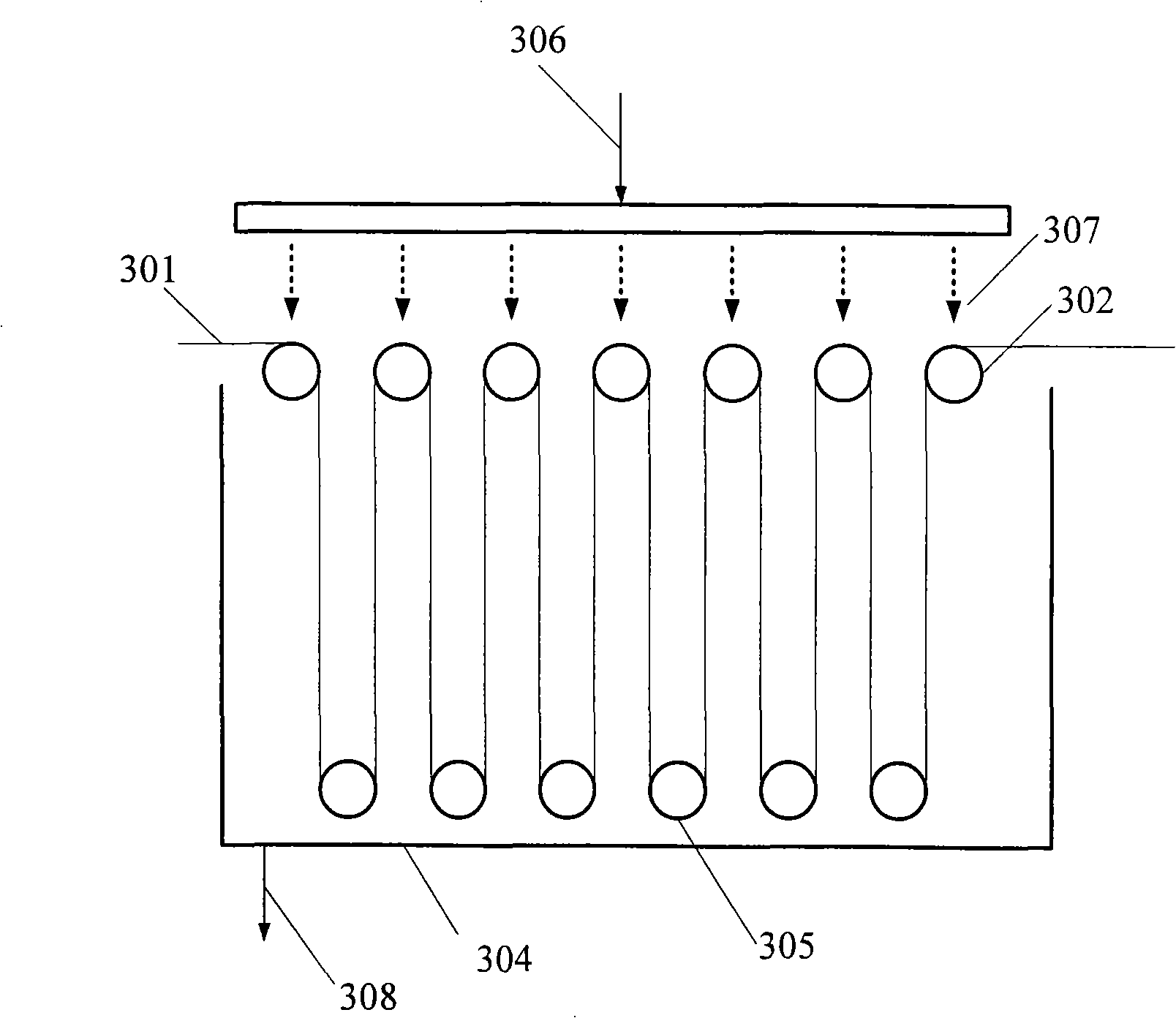

Method used

Image

Examples

Embodiment 1

[0047] The raw materials are diaminoresorcinol and terephthalic acid in a molar ratio of 1:1, and 0.5% stannous chloride antioxidant of the total mass of the raw materials is added to prepare the DAR compound salt. The pre-polymerization adopts a tank-type stirred reactor (made of 316L stainless steel) with a volume of 3 cubic meters. Gradually raise the temperature, and when the temperature reaches 90°C, start to add 60 kg of polyphosphoric acid, 30 kg of phosphorus pentoxide, 15 g of stannous chloride antioxidant, and 30 kg of DAR compound salt. Agitation was applied to the reactor during the addition. After the addition was completed, the temperature was continued to rise to 100° C., and the reaction was carried out for 10 hours, and the reactor was filled with nitrogen for protection. After the reaction is completed, open the channel connecting the lower part of the reactor to the inlet of the twin-screw extruder, increase the nitrogen pressure to 5 standard atmospheres, ...

Embodiment 2

[0049] Diaminoresorcinol and terephthalic acid are prepared according to the molar ratio of 1:1.1, and 1.2% stannous chloride antioxidant is added to prepare DAR compound salt. The pre-polymerization adopts a tank-type stirred reactor with a volume of 3 cubic meters. Gradually raise the temperature, and when the temperature reaches 100°C, start to add 91.5 kg of polyphosphoric acid, 45 kg of phosphorus pentoxide, 1500 g of stannous chloride antioxidant, and 12 kg of DAR compound salt. Agitation was applied to the reactor during the addition. After the addition was completed, the temperature was further raised to 110° C., and the reaction was carried out for 9 hours, and the reactor was filled with argon for protection. After the reaction is completed, open the channel connecting the lower part of the reactor to the inlet of the twin-screw extruder, increase the argon pressure to 6 standard atmospheres, and press the material into the screw extruder. The temperature of the sc...

Embodiment 3

[0051]Diaminoresorcinol and terephthalic acid are prepared according to the molar ratio of 1:0.9, and 0.1% stannous chloride antioxidant is added to prepare DAR compound salt. The pre-polymerization adopts a tank-type stirred reactor with a volume of 3 cubic meters and the upper part is filled with nitrogen. Gradually raise the temperature, and when the temperature reaches 120°C, start to add 41 kg of polyphosphoric acid, 50 kg of phosphorus pentoxide, 1000 g of stannous chloride antioxidant, and 8 kg of DAR compound salt. Agitation was applied to the reactor during the addition. After the addition was completed, the temperature was continued to rise to 120° C., and the reaction was carried out for 10 hours, and the reactor was filled with nitrogen for protection. After the reaction is completed, open the channel connecting the lower part of the reactor to the inlet of the twin-screw extruder, increase the nitrogen pressure to 7 standard atmospheres, and press the material in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com