Polymerization curing device and preparation method for preparing polyimide patterned film

A technology for preparing polyimide and thin films, which is applied in the manufacture of semiconductor/solid-state devices, electrical components, circuits, etc., can solve the problems of limiting the density of packaging and wiring, deformation of the three-dimensional topography of the film, and changing the topography integrity of the patterned film.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

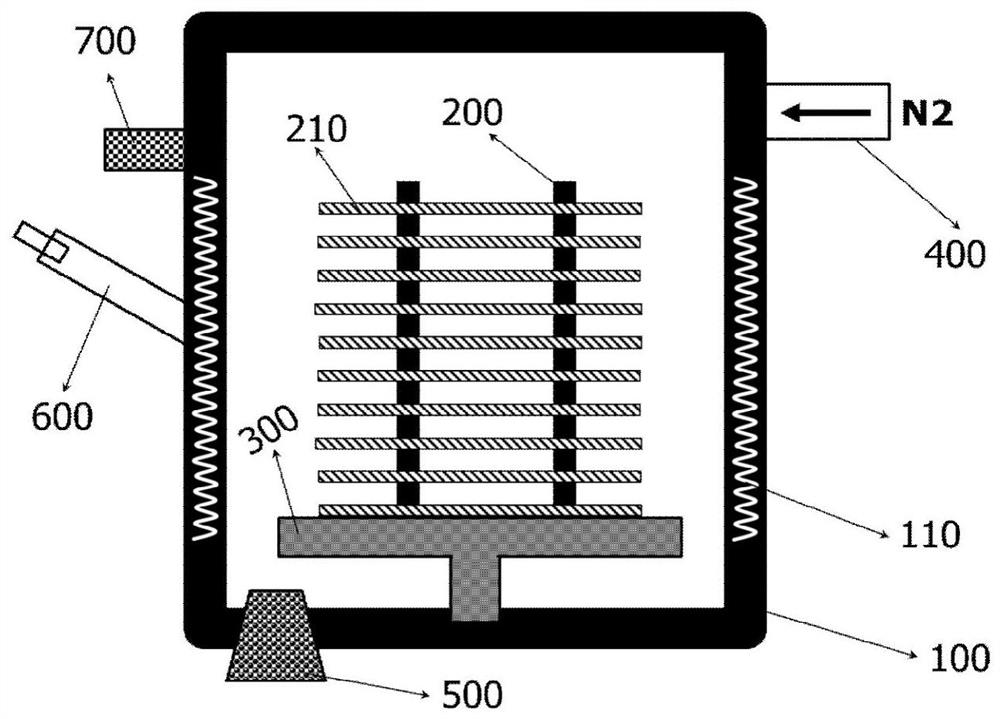

[0035] Such as figure 1 As shown, a polyimide patterned film preparation polymerization curing device, including a cavity 100, on the cavity 100 can be completely isolated from the outside world can be closed door (not shown), the cavity 100 side wall pre-prepared A number of cooling circulating water pipes 110 are buried, and a lifting platform 300 is provided in the cavity 100. A wafer support 200 is provided on the lifting platform 300. The wafer support 200 is provided with a plurality of heating plates that can individually heat the wafer along the vertical direction. 210, the cavity 100 is also provided with a nitrogen gas inlet 400, an air pressure detection device 700, a temperature detection device 600, and a vacuum pump 500, the temperature detection device 600 is a temperature sensor, and the detection direction of the temperature sensor is directed toward any wafer The heating plate 210 on the support 200.

[0036] A nitrogen inlet and a vacuum pump connected to t...

Embodiment 2

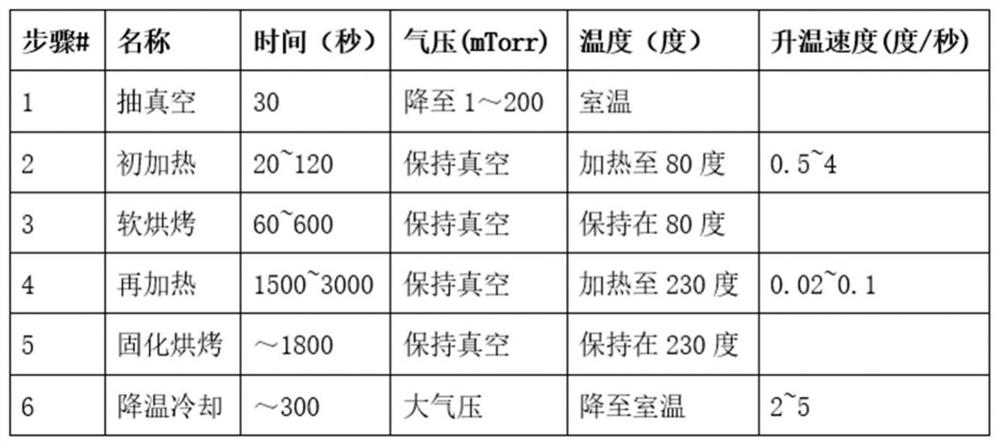

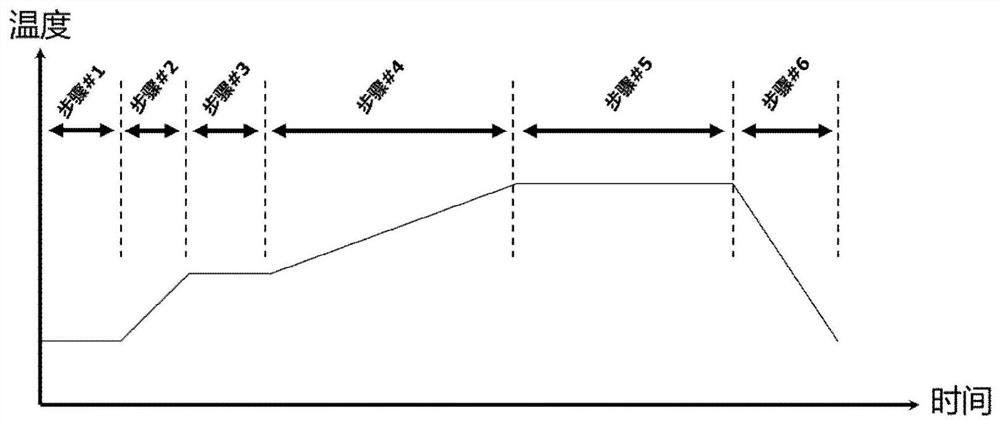

[0047] Such as Figure 1 to Figure 4 Shown, a kind of preparation method of polyimide patterned film comprises the following steps:

[0048] 1) The manipulator clamps and transports multiple wafers to each heating plate 210 in the cavity 100;

[0049] 2) Close the sealable door, and vacuumize the cavity 100, so that the air pressure in the cavity 100 reaches a vacuum state of the order of mTorr;

[0050] 3) heating the cavity 100 at a rate of 0.5-4°C / s to 80°C;

[0051] 4) The cavity 100 is kept at 80°C for 60-600s;

[0052] 5) heating the cavity 100 at a rate of 0.02-0.1°C / s to 230°C;

[0053] 6) The cavity 100 is kept at 230°C for 1800s;

[0054] 7) Cool down the cavity 100 at a rate of 2-5° C. / s to room temperature.

[0055] In step 2) to step 6), the vacuum state of mTorr level is always maintained in the cavity 100 .

[0056] In step 2) to step 6), while the nitrogen generator is supplying nitrogen, the vacuum pump 500 is turned on at the same time to evacuate, so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com