Preparation method of large-flux and high-density graphene heat-conducting film and product obtained

A large-flux, graphene technology, applied in the field of graphene, can solve the problems of the orderliness and compactness of the internal structure of the finished film, the long preparation time of the finished film, and the difficulty in reducing the production cost of the heat-conducting film, etc., to improve the preparation Efficiency and finished product quality, adjustable thickness, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

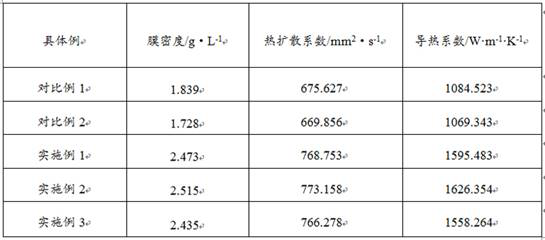

Examples

Embodiment 1

[0028] A method for preparing a large-flux and high-density graphene heat-conducting film, comprising the following steps:

[0029] Granulate graphene oxide into 0.5mm particles, weigh 10g of deionized water, weigh granulated graphene oxide according to 1% of the quality of deionized water, add it to deionized water, and use a high-speed mixer at 1500rpm to stir and disperse for 10min. Then carry out 120MPa homogeneous treatment to obtain a coating slurry with a viscosity of 10000MPa s;

[0030] Using an injection molding process, inject the obtained coating slurry into a glass substrate model with a length and width of 1cm×1cm and a thickness of 1mm through an injection molding machine;

[0031] Put the obtained base film into a microwave vacuum machine for a microwave treatment, the microwave power is 500W, and the treatment time is 1000s to obtain a dry film;

[0032] The obtained primary dry film is subjected to a rolling process using a roller machine, and the rolling pr...

Embodiment 2

[0036] A method for preparing a large-flux and high-density graphene heat-conducting film, comprising the following steps:

[0037] Granulate graphene oxide into 2mm particles, weigh 1kg of deionized water, weigh granulated graphene oxide according to 4% of the quality of deionized water, add it to deionized water, use a high-speed mixer at 1800rpm to stir and disperse for 15min, and then Carry out 150MPa homogeneous treatment to obtain a coating slurry with a viscosity of 80000MPa s;

[0038] Using injection molding process, the obtained coating slurry is injected into the mold of the glass substrate with a length and width of 25cm×30cm and a thickness of 5mm through an injection molding machine;

[0039] Put the obtained base film into a microwave vacuum machine for a microwave treatment, the microwave power is 1000W, and the treatment time is 500s to obtain a dry film;

[0040] The obtained primary dry film is subjected to a rolling process using a roller machine, and the ro...

Embodiment 3

[0044] A method for preparing a large-flux and high-density graphene heat-conducting film, comprising the following steps:

[0045] Graphene oxide was granulated into 1cm particles, weighed 10kg of deionized water, weighed granulated graphene oxide according to 20% of the quality of deionized water, added to deionized water, and stirred and dispersed with a high-speed mixer at 3000rpm for 60min, and then Carry out 180MPa homogeneous treatment to obtain a coating slurry with a viscosity of 100000MPa s;

[0046] Using injection molding process, the obtained coating slurry is injected into the mold of the glass substrate with a length and width of 40cm×40cm and a thickness of 10mm through an injection molding machine;

[0047] Put the obtained base film into a microwave vacuum machine for a microwave treatment, the microwave power is 1500W, and the treatment time is 10s to obtain a dry film;

[0048] The obtained primary dry film is subjected to a rolling process using a roller ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com