Ultrasonic-assisted preparation method of 2219 aluminum-based high-entropy alloy composite material

A technology of aluminum alloy materials and high-entropy alloys, applied in the field of ultrasonic-assisted preparation of 2219 aluminum-based high-entropy alloy composite materials, can solve problems such as agglomeration, unfavorable composite material strength, and promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

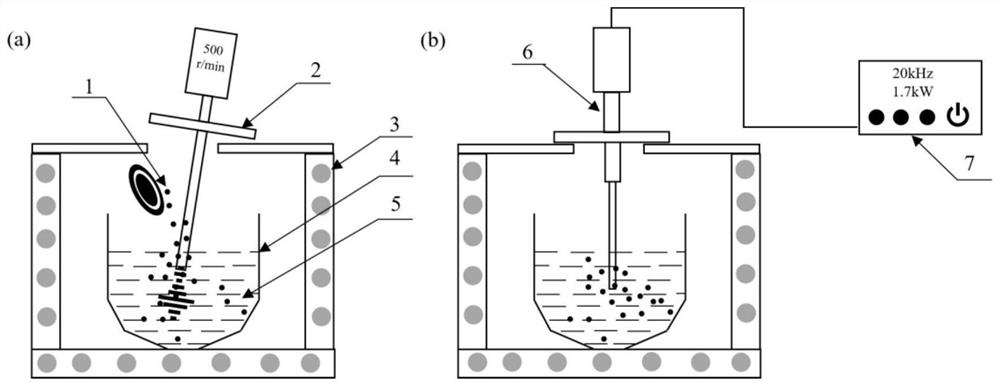

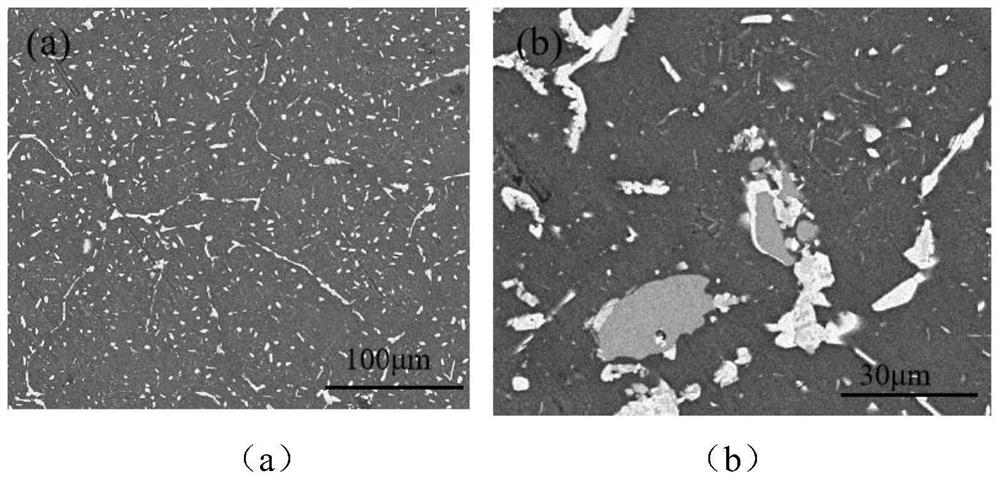

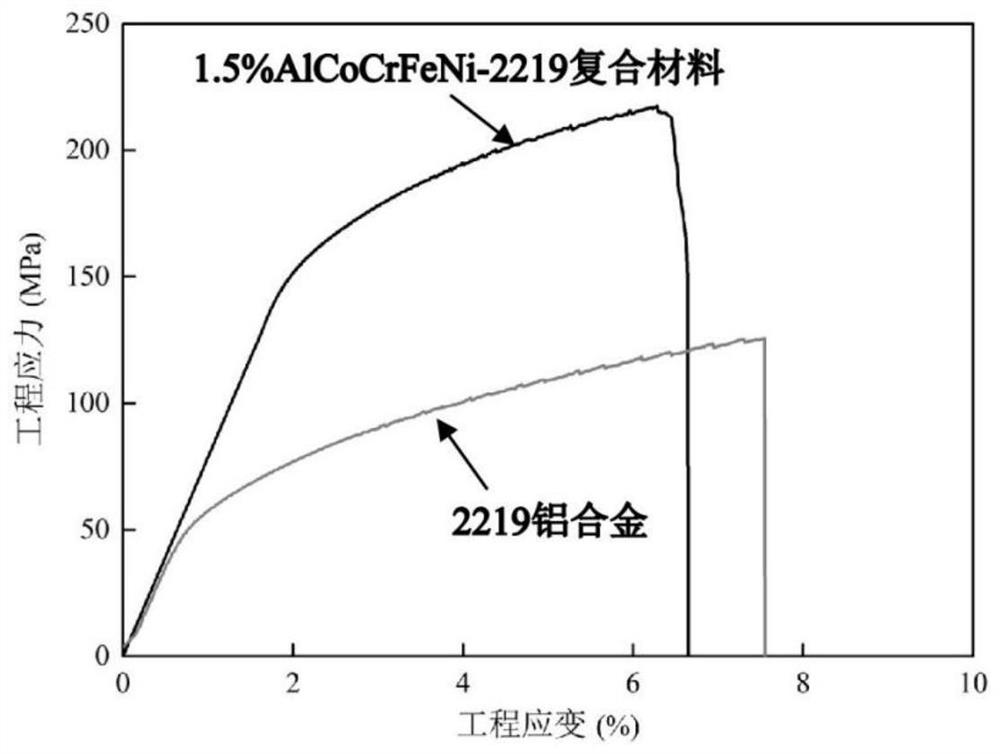

[0028] The purpose of the invention is to prepare a 2219 aluminum-based AlCoCrFeNi high-entropy alloy composite material, which is a metal-based composite material. The principle is to improve the wettability of AlCoCrFeNi high-entropy alloy particles in contact with melt atoms through the high-energy shock wave and high-speed micro-jet generated by ultrasonic cavitation bubble collapse, and promote the penetration of aluminum alloy melt atoms into the surface of high-entropy alloy particles and produce The boundary adsorption layer, on the one hand, promotes the preferential nucleation at the high-entropy alloy particles during the crystallization of the melt, on the other hand, improves the bonding interface structure between the high-entropy alloy particles and the melt, reduces the generation of defects such as bubbles and porosity, and impro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com