Cold-stacking high-whiteness saving-type dyeing and finishing pretreatment process for towel fabric under reclaimed water condition

A treatment process and high whiteness technology, applied in the field of textile printing and dyeing, to achieve the effects of shortening working hours, significant indirect economic benefits, and reducing use costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Pure cotton 32s / 2 ply towel, white.

[0030] Cold pile high whiteness saving dyeing and finishing pretreatment process of towel fabric under the condition of reclaimed water, the specific operation steps are as follows:

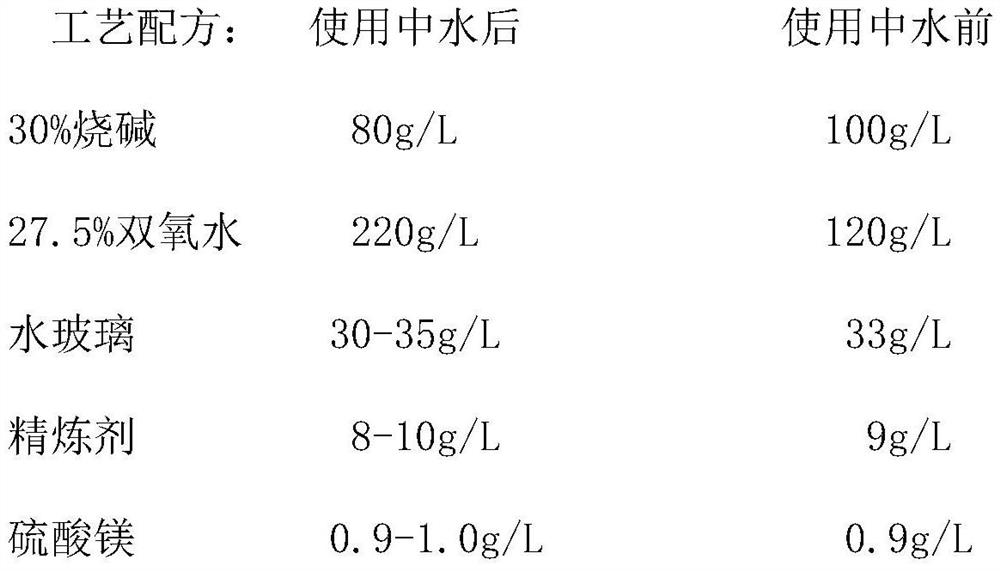

[0031] (1) Cold pile: the auxiliary agent and process consumption used are as shown in Table 1;

[0032] Table 1

[0033]

[0034]

[0035] (2) Boil the bottom: the auxiliary agent and process consumption used are as shown in table 2;

[0036] Table 2

[0037] Additive name Process usage 27.5% hydrogen peroxide 19g / L Brightener 4BK 0.4g / L Boiling temperature 98℃ Boil time 50min

Embodiment 2

[0039] Pure cotton 21s towel, camel color.

[0040] Cold pile high whiteness saving dyeing and finishing pretreatment process of towel fabric under the condition of reclaimed water, the specific operation steps are as follows:

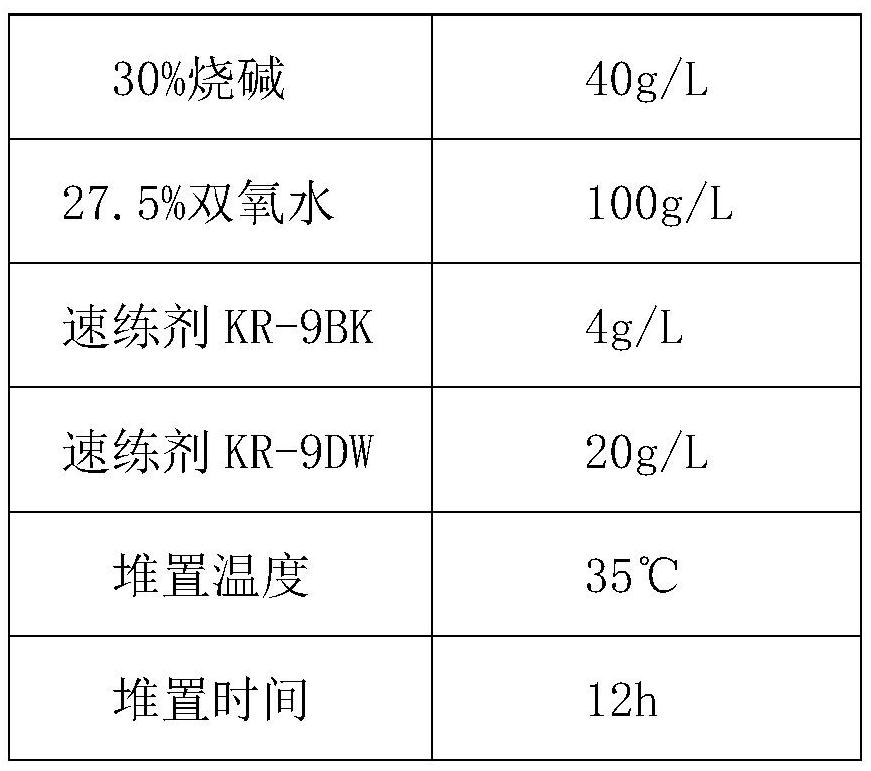

[0041] (1) Cold pile: the auxiliary agent and process consumption used are as shown in Table 3;

[0042] table 3

[0043]

[0044]

[0045] (2) Boil the bottom: the auxiliary agent and process consumption used are as shown in table 4;

[0046] Table 4

[0047] Additive name Process usage 27.5% hydrogen peroxide 9.6g / L Boiling temperature 98℃ Boil time 50min

[0048] The quick training agent used in the present invention is KR-9BK and KR-9DW, which is composed of KR-9BK and KR-9DW together to form a medium and low temperature rapid pretreatment process auxiliary system, wherein the quick training agent KR-9BK can be used under medium and low temperature conditions A scouring aid that exerts excellent emulsify...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com