Environment-friendly dust removal equipment for coal yard

A technology of environmental protection equipment and coal yards, which is applied to the separation of dispersed particles, chemical instruments and methods, and the use of liquid separation agents, etc., which can solve problems such as the obstruction of liquid atomization and diffusion, and the reduction of liquid diffusion area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025]Appendfigure 1 AdherentFigure 5 Down:

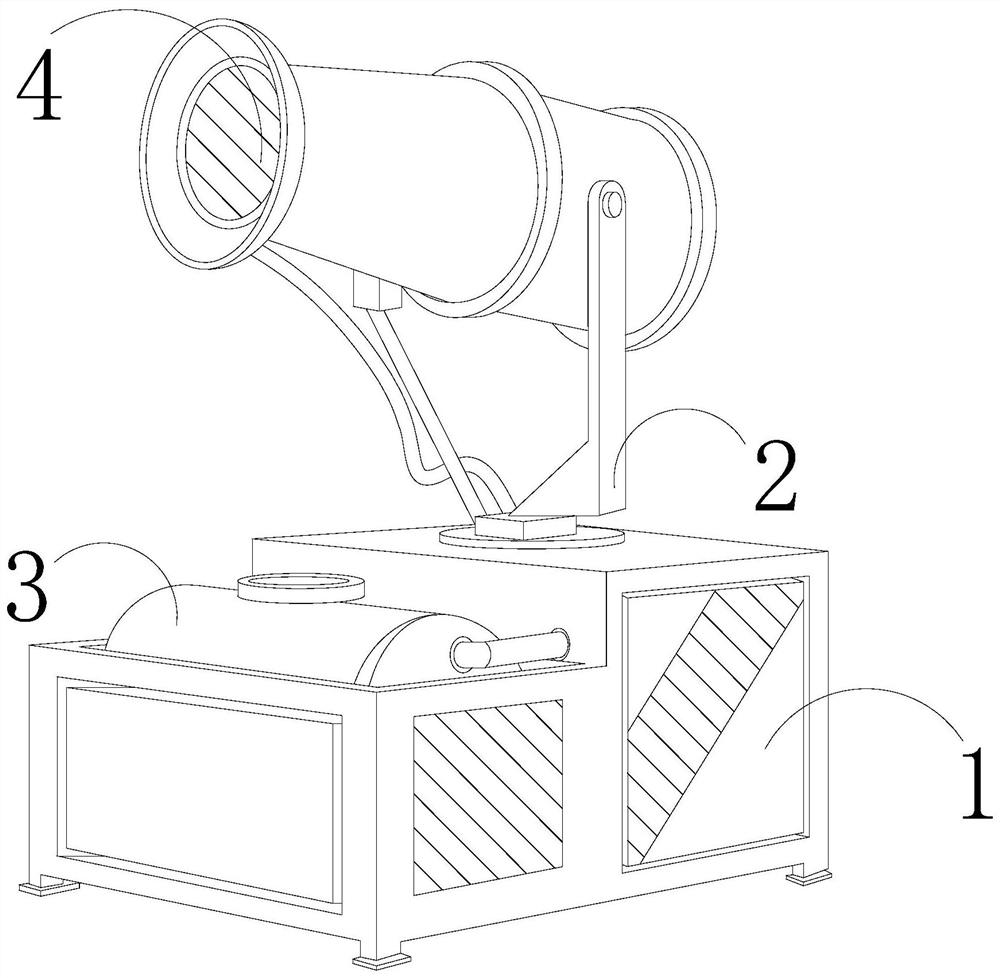

[0026]The present invention provides a coal field dust removal environmental protection device including a body 1, a support table 2, a water tank 3, an atomizer 4, and the support table 2 is attached to the center position of the body 1, the water tank 3 set in the body 1 On the top left, the atomizer 4 is fixed at the top of the support table 2.

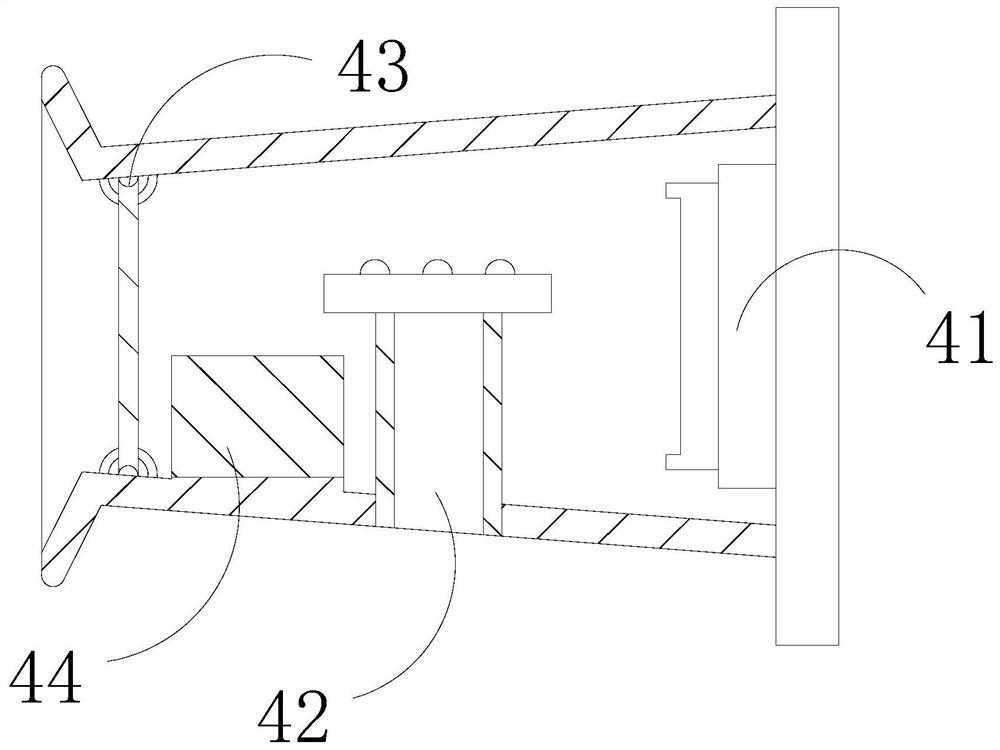

[0027]The atomizer 4 is provided with a fan 41, a nozzle 42, an atomizing mesh 43, a push mechanism 44, and the fan 41 is mounted at the inner wall inner wall of the atomizer 4, the nozzle 42 is disposed at the center of the atomizer 4. The atomization mesh 43 is inner inside the left end of the atomizer 4, the push mechanism 44 being fixed to the left end of the atomizer 4 and is located on the right side of the atomization network 43.

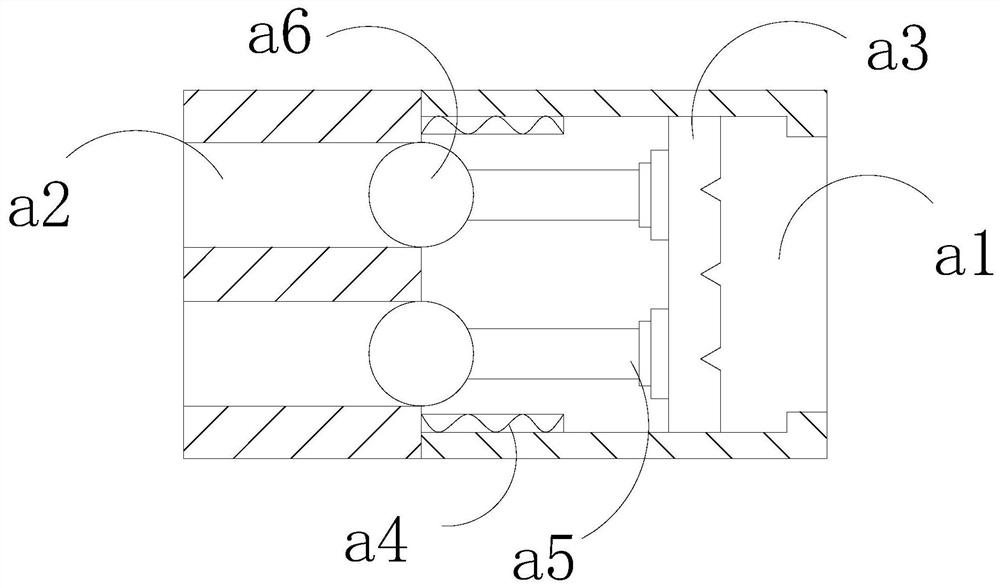

[0028]Wherein, the push mechanism 44 is provided with a bulk chamber A1, a rail A2, a restricted plate A3, a reset block A4, a connecting rod A5, a push ball A6, and...

Embodiment 2

[0034]AppendFigure 6 AdherentFigure 7Down:

[0035]Wherein, the push block D2 is provided with a block R1, a clear roller R2, a spray hole R3, and the top of the block R1 is provided with a clear roller R2, and the spray hole R3 penetrates the right side and the interior of the block R1, The spray hole R3 is in communication with the bottom surface of the purge roller R2, facilitating the trimming of the liquid roller R2 and the substance impact of the outer wall of the cleaning roller R2 can be removed.

[0036]Wherein, the cleaning roller R2 is provided with a support shaft T1, a roller t2, a push rod T3, a cleaning sheet T4, and the support shaft T1 located in the middle of the purge roller R2, the roller t2, which is outside the support shaft T1, which The cleaning tab T4 is mounted on the outer wall of the roller T2 by the push rod T2, and the outer wall of the roller t2 is a surface of the uneven, which can increase the force area of the outer wall of the roller T2 such that the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com