Co@NCNT material prepared by reduction-oxidation-reduction strategy and preparation method of Co@NCNT material

A Strategic, Oxidative Technology for Porous Materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This example provides a method for preparing a Co@NCNT material prepared by a reduction-oxidation-reduction strategy, including the following steps:

[0038] (1) Dimethylimidazole (12mmol) was added into anhydrous methanol (75mL), dissolved by ultrasonication for 3min to obtain an organic ligand solution; Co(NO 3 ) 2 ·6H 2 O (3mmol) was dissolved in anhydrous methanol (75mL) to obtain a Co salt solution;

[0039] (2) Add the Co salt solution in step (1) to the organic ligand solution, stir at room temperature for 15 minutes, and after standing for 24 hours, filter the resulting solution, wash with anhydrous methanol three times, and dry at 60°C to obtain the ZIF-67 material ;

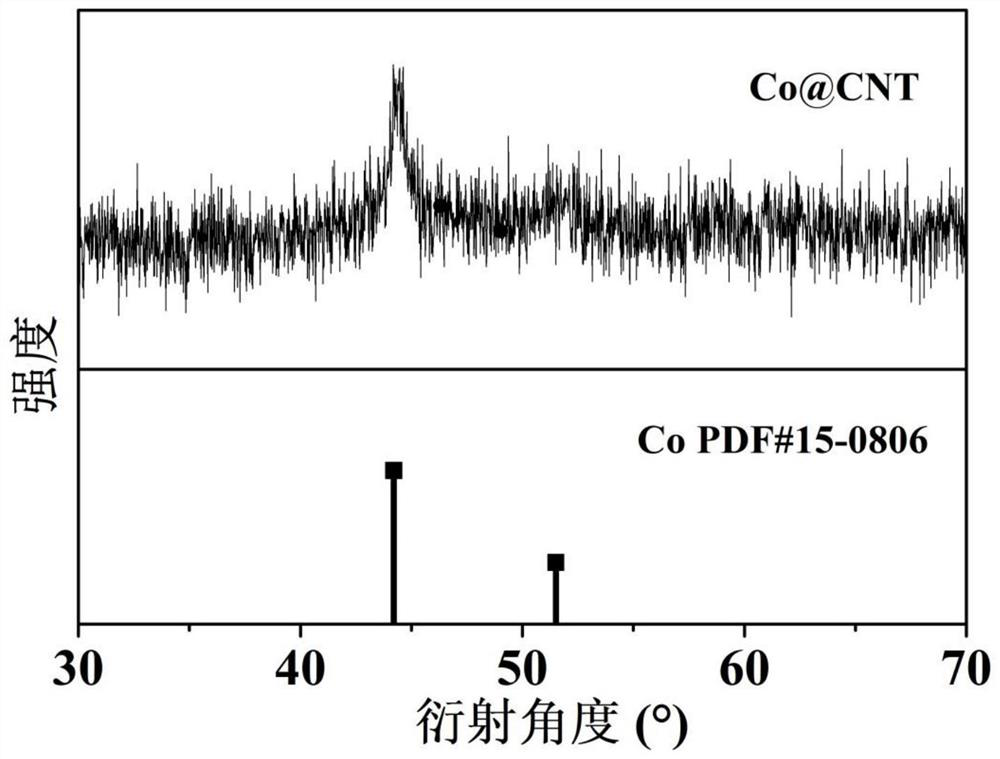

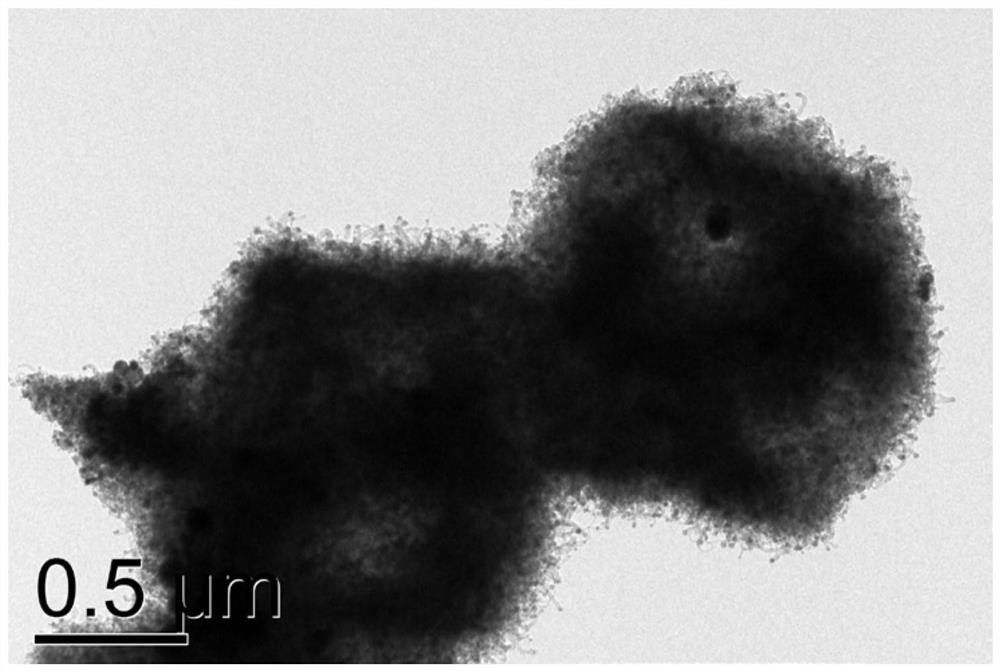

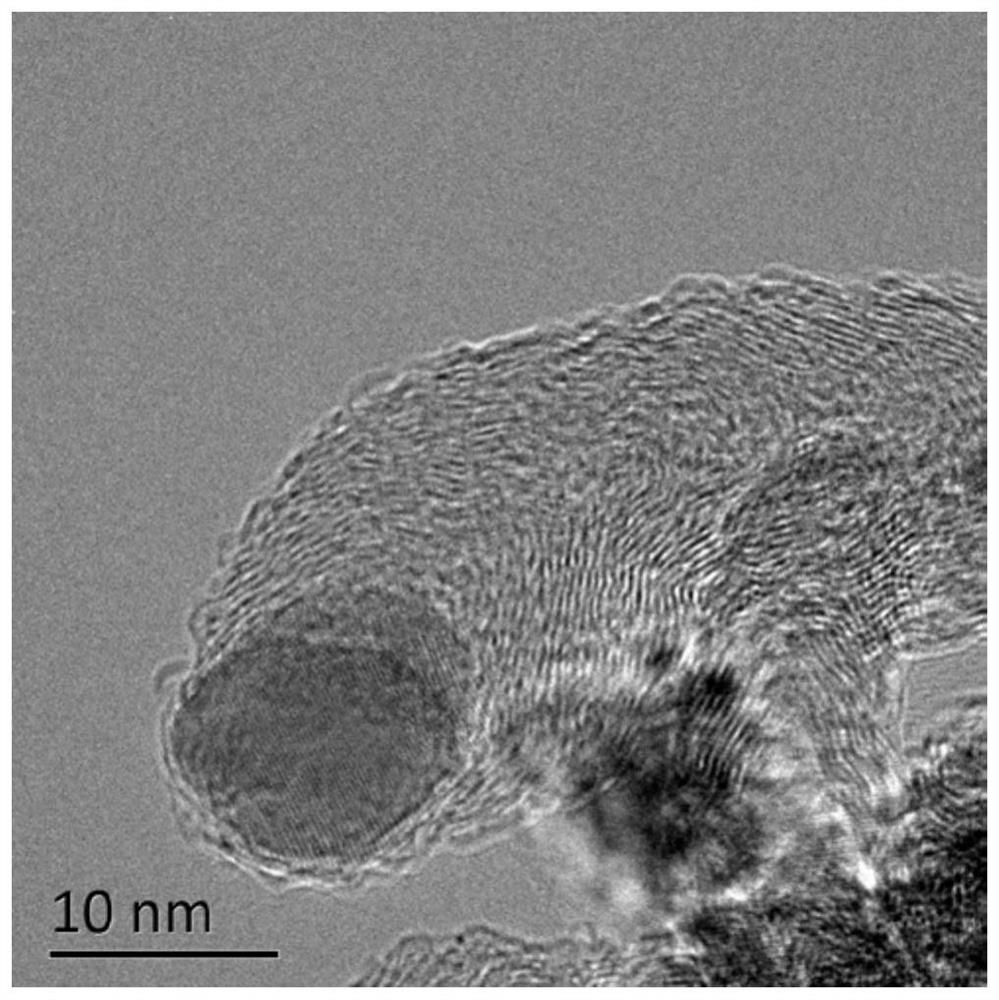

[0040] (3) Weigh 0.5g of ZIF-67 obtained in step (2), spread it on a quartz boat, place it in a tube furnace for pyrolysis, and pyrolyze it at 600°C for 3 hours at a constant temperature to obtain Co nano A Co@C@NCNT material covered with a carbon film on the particle surface.

[0041] (4) W...

Embodiment 2

[0047] This example provides a method for preparing a Co@NCNT material prepared by a reduction-oxidation-reduction strategy, including the following steps:

[0048] (1) Dimethylimidazole (12mmol) was added into anhydrous methanol (75mL), dissolved by ultrasonication for 3min to obtain an organic ligand solution; Co(NO 3 ) 2 ·6H 2 O (3mmol) was dissolved in anhydrous methanol (75mL) to obtain a Co salt solution;

[0049] (2) Add the Co salt solution in step (1) to the organic ligand solution, stir at room temperature for 15 minutes, and after standing for 24 hours, filter the resulting solution, wash with anhydrous methanol three times, and dry at 60°C to obtain the ZIF-67 material ;

[0050] (3) take by weighing the ZIF-67 that 0.5g step (2) obtains, tile in the quartz boat, place tube furnace pyrolysis, pyrolysis atmosphere is the mixed gas of hydrogen and argon (H 2 :Ar=10:90), pyrolyzed at 600°C for 3h at a constant temperature to obtain a Co@C@NCNT material covered wit...

Embodiment 3

[0055] This example provides a method for preparing a Co@NCNT material prepared by a reduction-oxidation-reduction strategy, including the following steps:

[0056] (1) Dimethylimidazole (12mmol) was added into anhydrous methanol (75mL), dissolved by ultrasonication for 3min to obtain an organic ligand solution; Co(NO 3 ) 2 ·6H 2 O (3mmol) was dissolved in anhydrous methanol (75mL) to obtain a Co salt solution;

[0057] (2) Add the Co salt solution in step (1) to the organic ligand solution, stir at room temperature for 15 minutes, and after standing for 24 hours, filter the resulting solution, wash with anhydrous methanol three times, and dry at 60°C to obtain the ZIF-67 material ;

[0058] (3) take by weighing the ZIF-67 that 0.5g step (2) obtains, tile in the quartz boat, place tube furnace pyrolysis, pyrolysis atmosphere is the mixed gas of hydrogen and argon (H 2 :Ar=10:90), pyrolyzed at 600°C for 3h at a constant temperature to obtain a Co@C@NCNT material covered wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com