Nitrosation SBR device for promoting short-cut nitrification by adding hydrazine and improved process

A short-range nitrification and nitrosation technology, applied in the field of nitrosation SBR reactor to promote short-range nitrification, can solve the problems of inability to be biodegraded, eutrophication of water body, carcinogenicity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

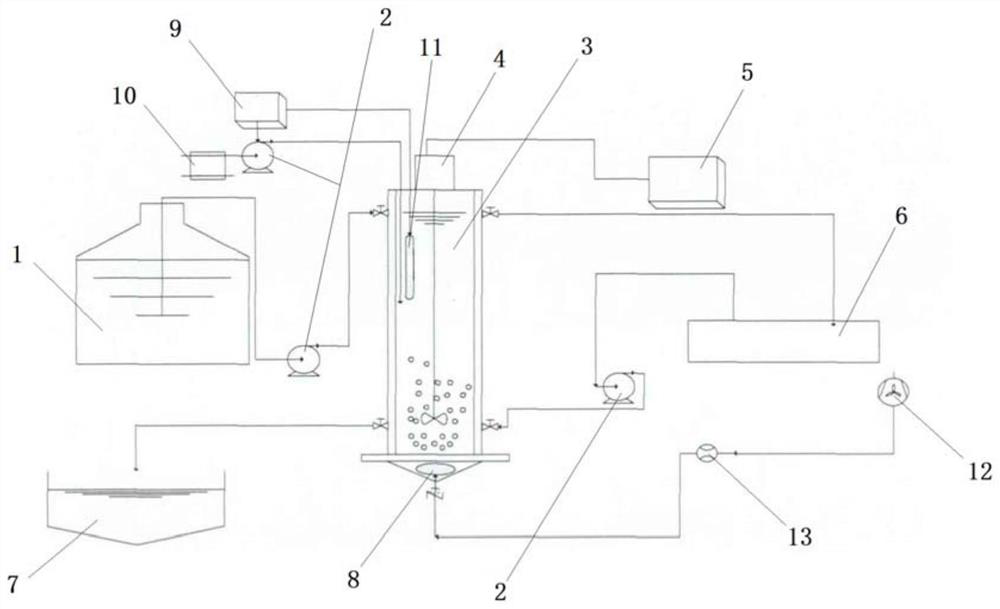

Method used

Image

Examples

Embodiment 1

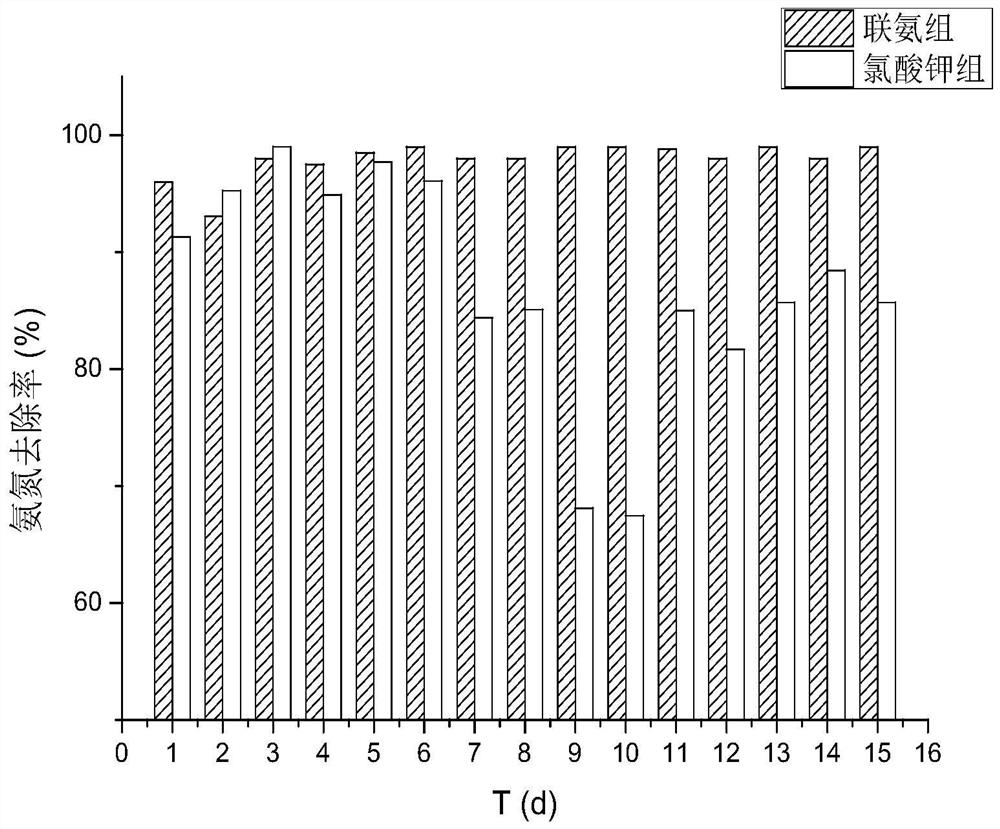

[0043] In this embodiment, the ammonia nitrogen removal rate of the nitrosation SBR improved process of adding hydrazine is as follows: figure 2 As shown, during the 15-day operation, the ammonia nitrogen removal rate of the hydrazine group was stable at 98%-99%.

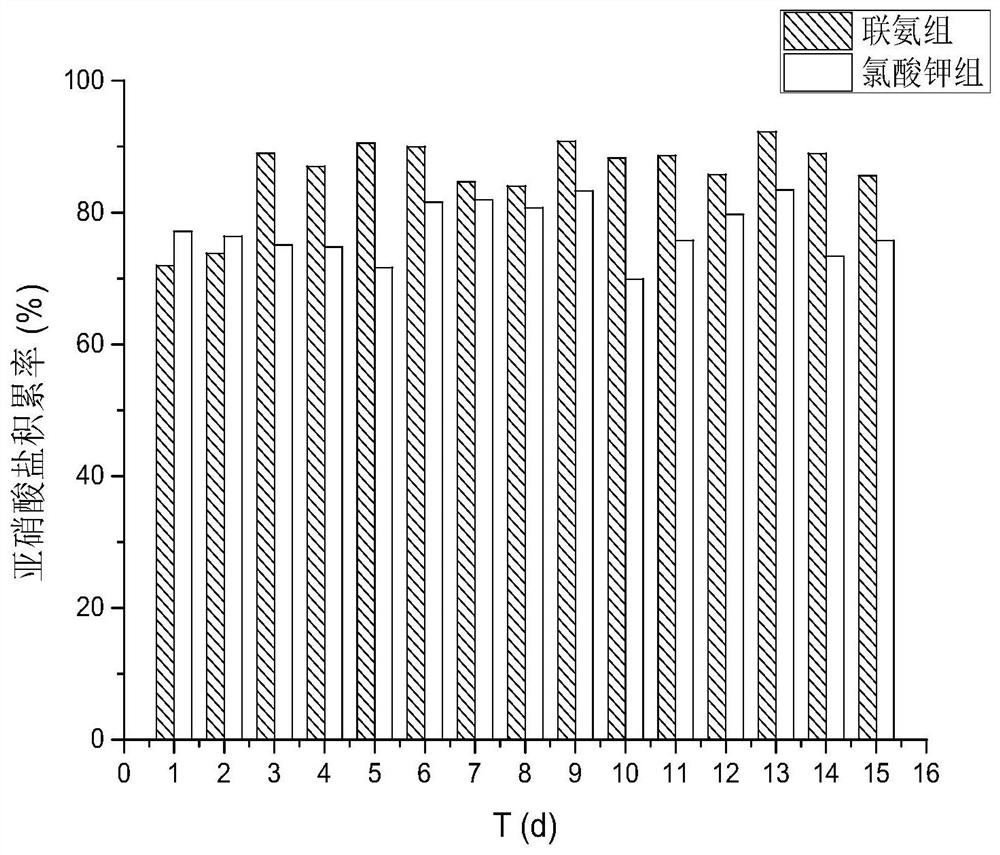

[0044] In this embodiment, the nitrite accumulation rate of the nitrosation SBR improved process of adding hydrazine is as follows: image 3 It was shown that during the 15-day operation, the highest nitrite accumulation rate of the hydrazine group could reach 92.26%, and the average nitrite accumulation rate was 86.08%.

[0045] In this embodiment, the sludge concentration change of the nitrosation SBR improvement process of adding hydrazine is as follows: Figure 4 As shown, during the 15-day operation, although the sludge growth was limited to some extent, it did not adversely affect the system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com