IPDI type transparent high-strength polyurethane plate and preparation method thereof

A high-strength, polyurethane technology, used in chemical instruments and methods, mixers, mixers with rotary stirring devices, etc., can solve problems such as low transparency, incomplete crystallization of raw materials, and incomplete cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

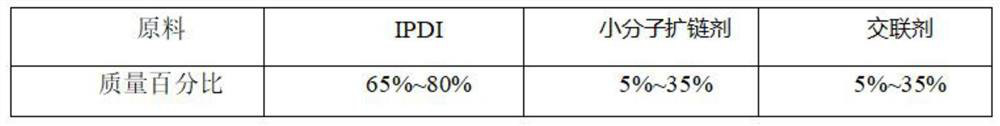

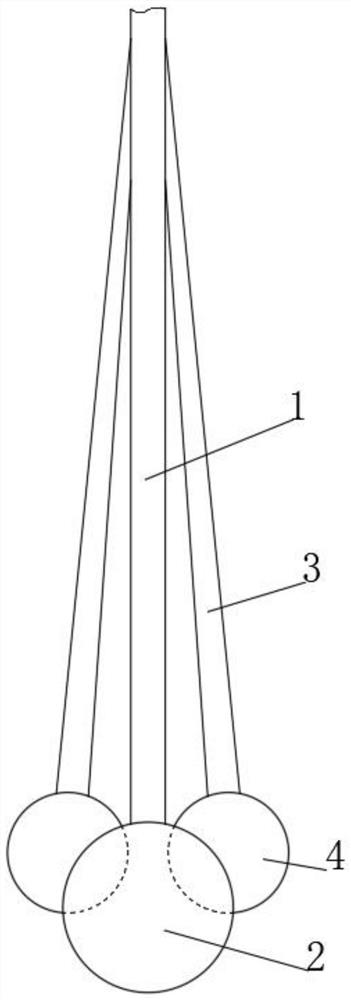

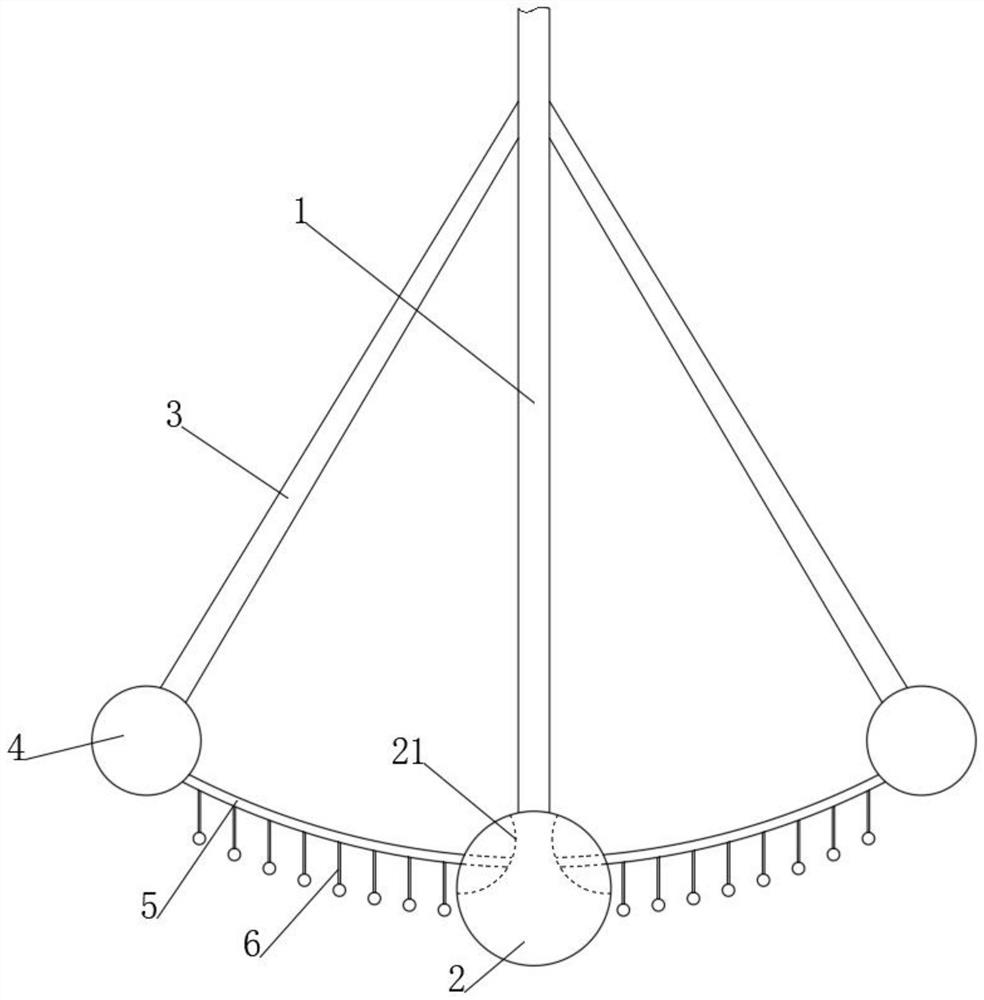

[0046]Seefigure 1 An IPDI-type transparent high-intensity polyurethane sheet comprising: 71% isophorone diisocyanate IPDI, 14% small molecular chain extender, and 15% crosslinking agent.

[0047]An IPDI-type transparent high strength polyurethane sheet, the preparation method thereof includes the following steps:

[0048]S1, A material preparation:

[0049]S11, add BDO to a three-mouth flask equipped with a toner mixer, heated to 110 ° C, dehydrated under vacuum, so that the mass fraction of water in the material is not higher than 0.05%, and the temperature is lowered to 80 ° C;

[0050]S12, the dehydrated BDO is added to the measured IPDI, maintaining the heating of the heating at 80 ° C for 3 h, reaching the theoretical NCO content;

[0051]S2, B material preparation: Heat the crosslinking agent to 80 ° C as B material.

[0052]S3, pouring: mixing A, B material, stirred for 3 minutes, cast into the mold, and standing at 80 ° C for 2 h, then demolding, resulting in finished products;

[0053]S4, test:...

Embodiment 2

[0057]Seefigure 1 An IPDI-type transparent high-intensity polyurethane sheet comprising the following components of mass sharing: 65% isophorone diisocyanate IPDI, 5% small molecular chain extender and 35% crosslinking agent.

[0058]An IPDI-type transparent high strength polyurethane sheet, the preparation method thereof includes the following steps:

[0059]S1, A material preparation:

[0060]S11, add BDO to a three-mouth flask equipped with a toner mixer, heated to 110 ° C, dehydrated under vacuum, so that the mass fraction of water in the material is not higher than 0.05%, and the temperature is lowered to 80 ° C;

[0061]S12, the dehydrated BDO is added to the measured IPDI, maintaining the heating of the heating at 80 ° C for 3 h, reaching the theoretical NCO content;

[0062]S2, B material preparation: Heat the crosslinking agent to 80 ° C as B material.

[0063]S3, pouring: mixing A, B material, stirred for 1.5 minutes, cast into the mold, and standing at 80 ° C for 2 h, then demolding, resul...

Embodiment 3

[0066]Seefigure 1 An IPDI-type transparent high-strength polyurethane sheet, including the following components of mass: 80% isophorone diisocyanate IPDI, 35% small molecular chain extender and 5%-crosslinking agent.

[0067]An IPDI-type transparent high strength polyurethane sheet, the preparation method thereof includes the following steps:

[0068]S1, A material preparation:

[0069]S11, add BDO to three flasks equipped with a very temperature mixer, a thermometer, heated to 100 ° C, dehydrated under vacuum, so that the mass fraction of water in the material is not higher than 0.05%, and the temperature is reduced to 80 ° C.

[0070]S12, the dehydrated BDO is added to the measured IPDI, and the heating and stirring reaction at 80 ° C is maintained at 80 ° C for 2 h, reaching the theoretical NCO content;

[0071]S2, B material preparation: Heat the crosslinking agent to 80 ° C as B material.

[0072]S3, pouring: mixing A, B material, stirred for 2 minutes, cast into the mold, and standing at 80 ° C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com