Collagenous fiber-based flexible pressure sensing material and preparation method thereof

A technology of collagen fibers and sensing materials, applied in the field of flexible sensing, which can solve the problems of complex preparation process, difficulty in large-scale industrial production, and large thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

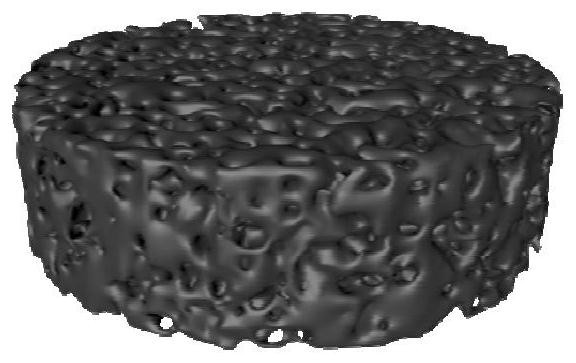

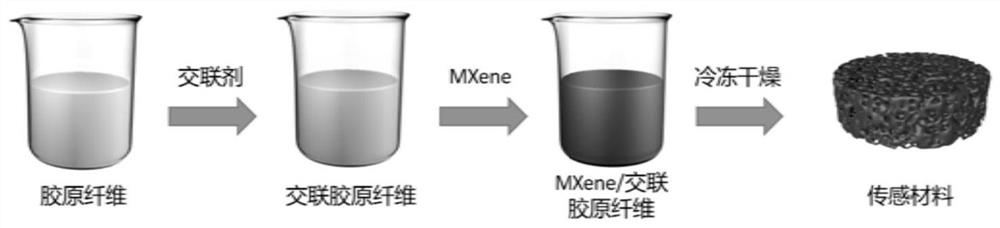

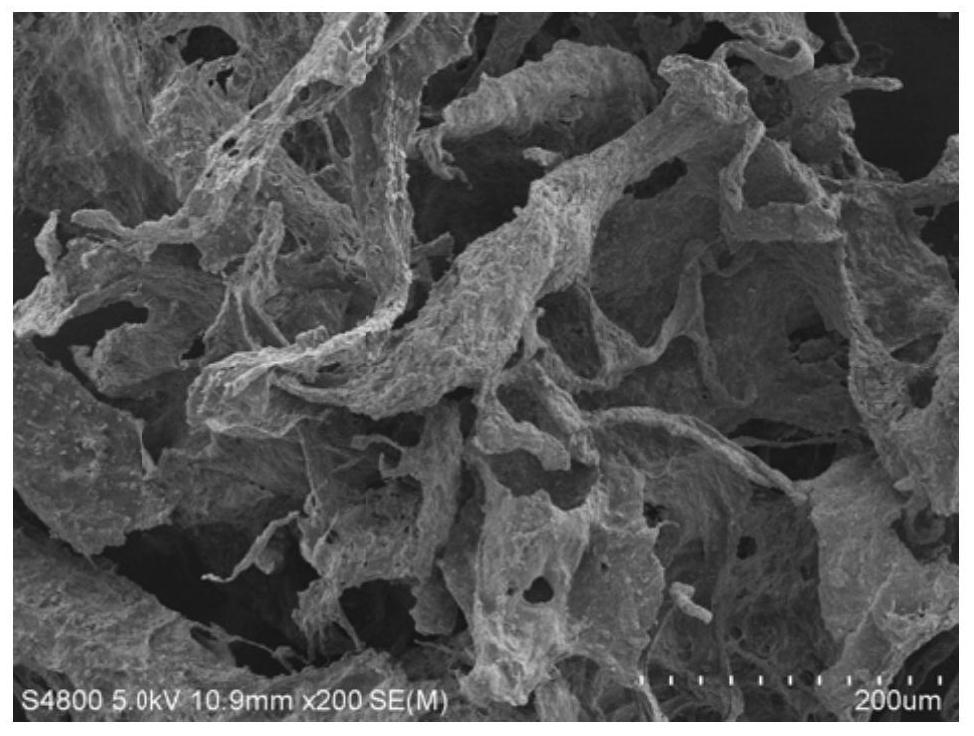

Embodiment 1

[0043] Select sheepskin collagen fiber as base material, when pH=5.5, mix the 25% glutaraldehyde aqueous solution of the mass concentration 0.8% collagen fiber suspension of 10g with 0.032g (the solid content in the collagen fiber suspension and the quality of cross-linking agent ratio of 1:0.4), stirred at 25°C for 4h, and stirred at 45°C for 4h to obtain a suspension of cross-linked collagen fibers. Add 1.4% Ti by mass fraction to the resulting suspension of crosslinked collagen fibers 3 C 2 Dispersion liquid 3.14g (mass ratio of the solid content in the cross-linked collagen fiber suspension to the solid content in the MXene dispersion liquid is 1:0.5), after fully mixing, adjust the pH value to 3, and then stir for 1h to obtain Ti 3 C 2 / collagen fiber composite suspension. Ti 3 C 2 / collagen fiber composite suspension was put into a 25mL beaker, and freeze-dried at -30°C and 0.1Pa for 24h to obtain a sponge-like porous collagen fiber-based flexible pressure sensing m...

Embodiment 2

[0046] Select cowhide collagen fibers as the base material, and when pH=6, mix 10 g of the mass concentration 1% collagen fiber suspension with 0.012 g of genipin (the mass ratio of the solid content in the collagen fiber suspension to the crosslinking agent is 1 :0.12), stirred at 25°C for 24h to obtain a suspension of cross-linked collagen fibers. Add 0.5% Mo by mass fraction to the obtained suspension of crosslinked collagen fibers 2 Ti 2 C 3 Dispersion liquid 8.96g (mass ratio of the solid content in the cross-linked collagen fiber suspension to the solid content in the MXene dispersion liquid is 1:0.4), after fully mixing, adjust the pH value to 5, and then stir for 1.5h to obtain Mo 2 Ti 2 C 3 / collagen fiber composite suspension. The resulting Mo 2 Ti 2 C 3 / collagen fiber composite suspension was put into a 25mL beaker, and freeze-dried at -40°C and 0.1Pa for 40h to obtain a collagen fiber-based flexible pressure sensing material with a sponge-like porous struc...

Embodiment 3

[0048] Select pigskin collagen fibers as the base material, and when pH=5, mix 5 g of 3% collagen fiber suspension with a mass concentration of 0.012 g of catechin (the mass ratio of the solid content in the collagen fiber suspension to the crosslinking agent is 1:0.08), stirred at 35°C for 10 h to obtain a suspension of cross-linked collagen fibers. Add 0.78% Ti by mass fraction to the resulting suspension of crosslinked collagen fibers 2 C dispersion liquid 5.7g (mass ratio of the solid content in the cross-linked collagen fiber suspension to the solid content in the MXene dispersion liquid is 1:0.3), after fully mixing, adjust the pH value to 4, and then stir for 0.5h to obtain Ti 2 C / collagen fiber composite suspension. Ti 2 The C / collagen fiber composite suspension was put into a 25mL beaker, and freeze-dried at -20°C and 0.1Pa for 48h to obtain a collagen fiber-based flexible pressure sensing material with a sponge-like porous structure. The sensitivity of the obtaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com